Silkworm seed producing process

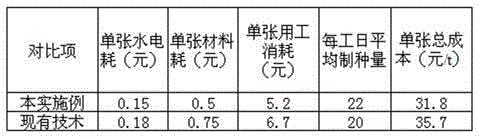

A silkworm seed and process technology, applied in the field of breeding, can solve problems such as affecting work quality and work efficiency, female moths are not fully mature, and increase production costs, so as to reduce the chance of contacting dead pupae, reduce the probability of infection, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A silkworm egg seed production process, the process comprises the steps of:

[0036] (1) Cocoon cutting: Carefully cut open the collected silk cocoons with a cocoon cutting tool, pour out the silkworm chrysalis and lay them on the plaque;

[0037] (2) Identification of pupae: sort the female pupae laid in the plaque into the empty plaque, and leave the male pupae in the original plaque, and re-identify the pupae while identifying the pupae, and control the accuracy rate of female and male identification > 99%;

[0038] (3) Laying pupae: Spread the male pupae obtained in step (2) in time into the seed production box covered with sawdust at the bottom and cover with moth cloth, and stack the seed production box with male pupae in the moth hair room In step (2), spread the female pupae obtained in step (2) on a plaque covered with sawdust at the bottom and then cover with moth cloth; the pupa density is 700-900 pupae / ㎡; the moth cloth is hygroscopic Good pure cotton mat...

Embodiment 2

[0052] A silkworm egg seed production process, the process comprises the steps of:

[0053] (1) Cocoon cutting: Carefully cut open the collected silk cocoons with a cocoon cutting tool, pour out the silkworm chrysalis and lay them on the plaque;

[0054] (2) Identification of pupae: Sorting the female pupae spread in the plaque into the empty plaque, leaving the male pupae in the original plaque, and re-identifying pupae while identifying pupae, controlling the accuracy rate of female and male identification > 99%;

[0055] (3) Laying pupae: spread the male pupae obtained in step (2) in time to the seed production box covered with sawdust at the bottom, cover with moth cloth, and stack the seed production box with male pupae in the moth chamber In step (2), spread the female pupae obtained in step (2) to the plaque covered with sawdust at the bottom and then cover with moth cloth; the pupae density is 900 pupae / ㎡;

[0056] (4) Hair moths: By adjusting the temperature, ensure...

Embodiment 3

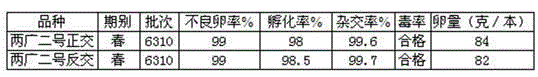

[0074] A kind of seed production technique of Liangguang No. 2 flat seed, the technique comprises the following steps:

[0075] (1) Cocoon cutting: Carefully cut open the collected silk cocoons with a cocoon cutting tool, pour out the silkworm chrysalis and lay them on the plaque;

[0076] (2) Identification of pupae: Sorting the female pupae spread in the plaque into the empty plaque, leaving the male pupae in the original plaque, and re-identifying pupae while identifying pupae, controlling the accuracy rate of female and male identification > 99%;

[0077] (3) Laying pupae: spread the male pupae obtained in step (2) in time to the seed production box covered with sawdust at the bottom, cover with moth cloth, and stack the seed production box with male pupae in the moth chamber In step (2), spread the female pupae obtained in step (2) in time on a plaque covered with sawdust at the bottom and cover with moth cloth; the pupa density is 800 pupae / ㎡; the moth cloth has good hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com