Through-type cleaner for cutting oil liquid

A technology of cleaner and cutting oil, applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve problems such as difficult to solve, and achieve the effect of sufficient separation, high processing efficiency, and easy recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

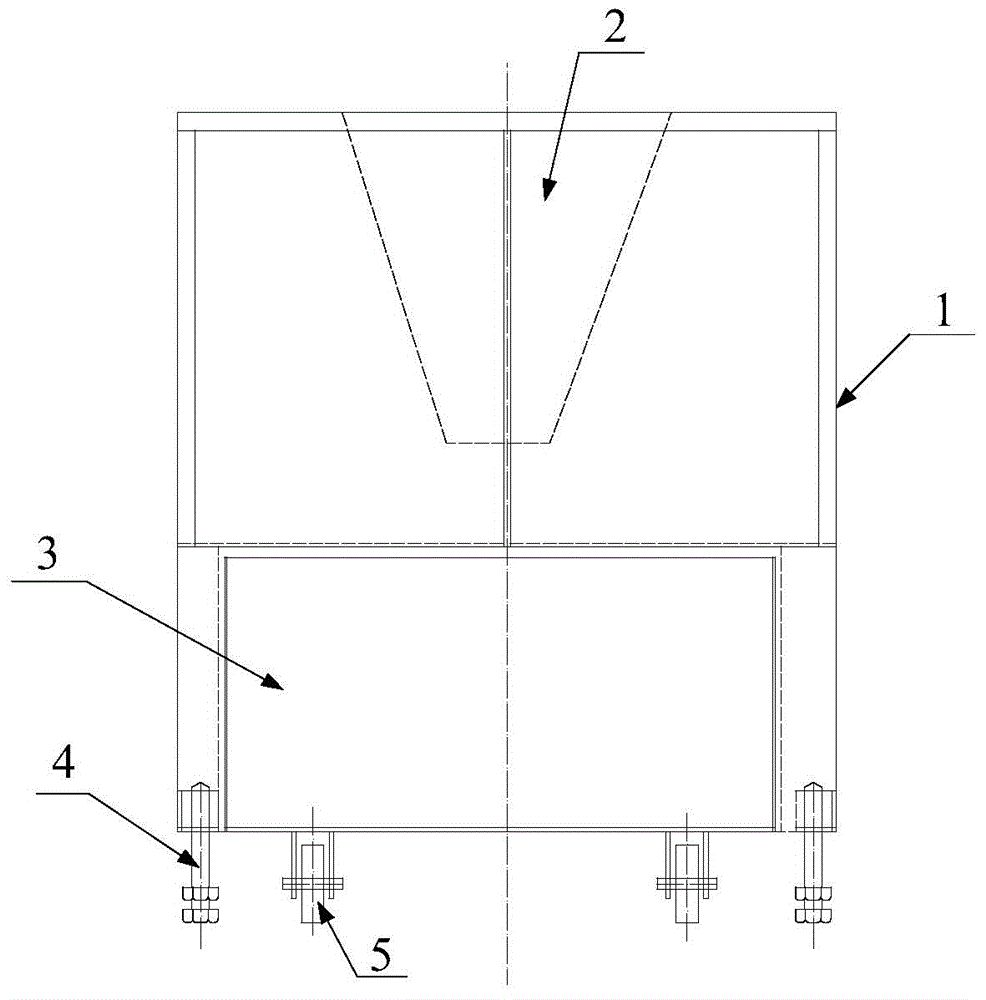

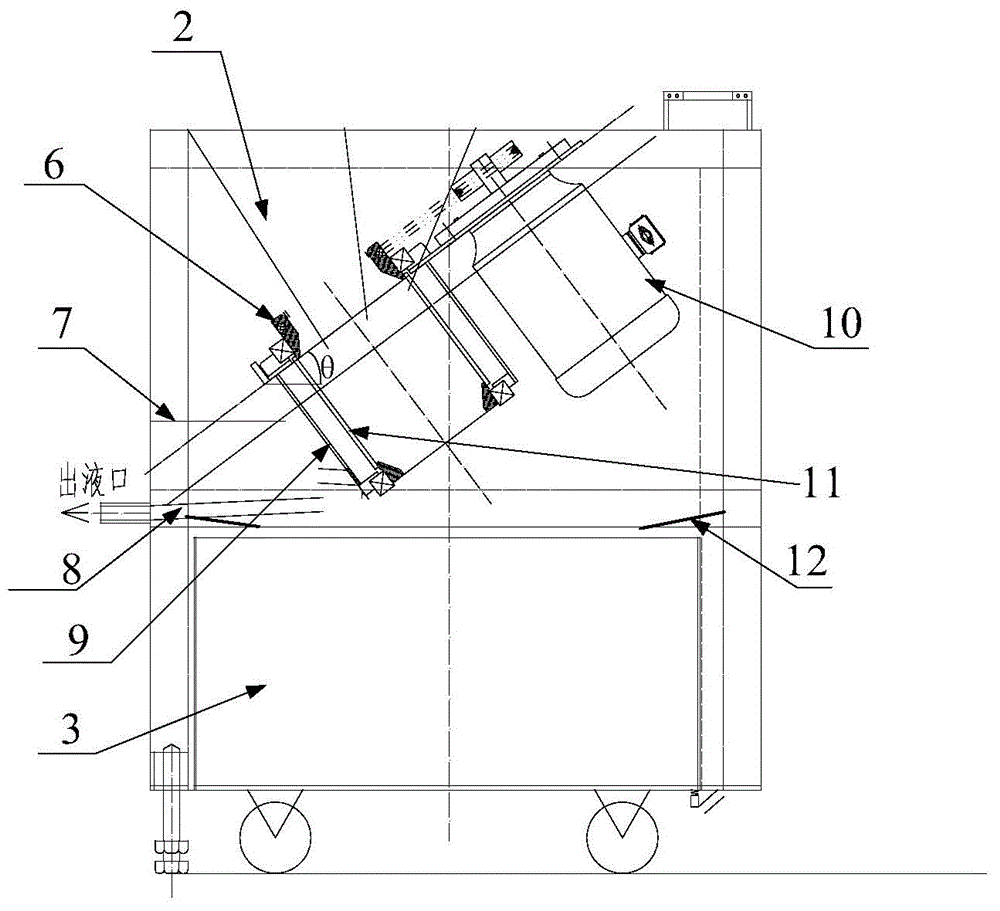

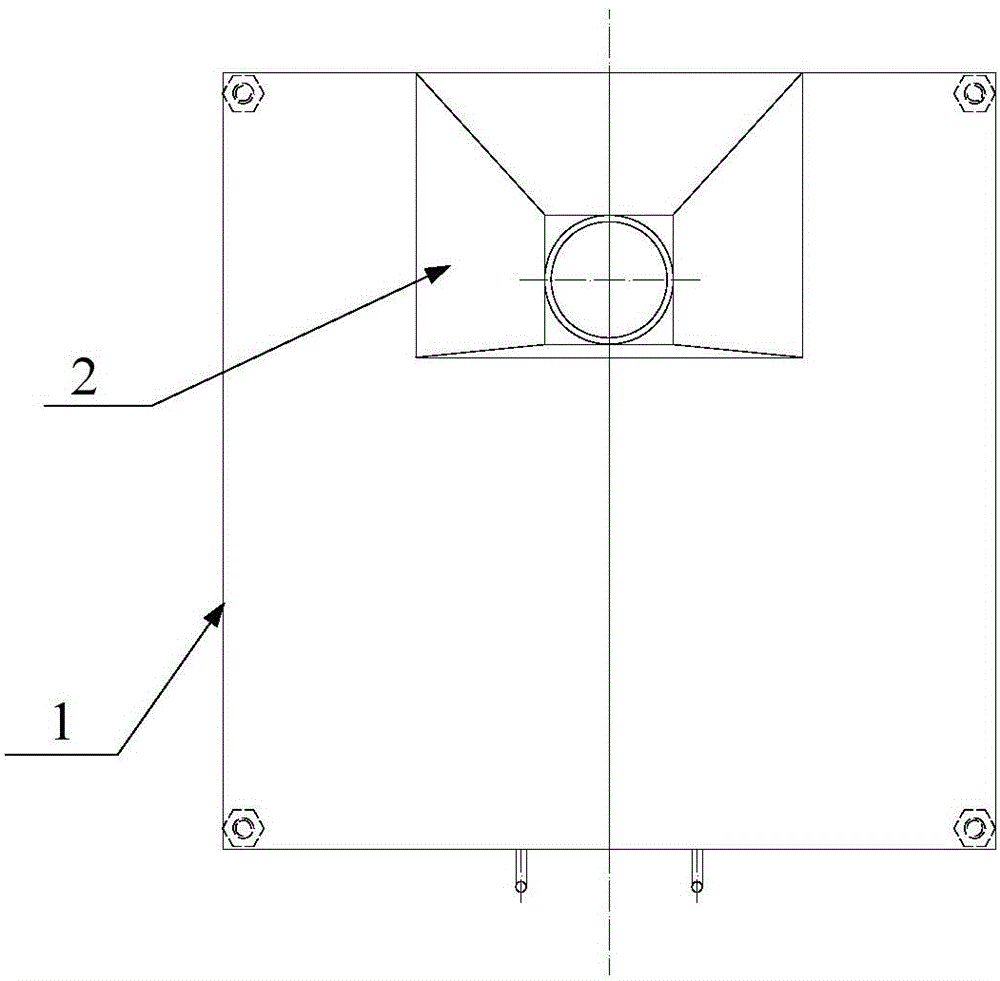

[0053] The present invention is an independent equipment unit, which is composed of main parts such as chip inlet, separator 9, frequency conversion motor 10, electric control unit, liquid outlet, chip receiving box 3, chip discharge controller and alarm.

[0054] see Figure 1 to Figure 3 , the present invention comprises cabinet body 1, and rail 7 is arranged in cabinet body 1, and cylindrical separator 9 is fixedly installed on rail 7, and the fixed position of separator 9 can be adjusted on rail 7 according to usage conditions, and separator 9 It is used to separate cutting oil and chips; the separator 9 is set obliquely, and there is an angle θ between its end face and the horizontal plane, such as figure 2 As shown, in order to be suitable for chips of different materials, the angle θ ranges from 27° to 75°, which can meet the different angle requirements of carbon fiber materials, non-ferrous metals, steel parts, hard alloys and diamonds.

[0055] The separator 9 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com