Flue gas desulfurization and denitrification device and method of coal fired boiler

A coal-fired boiler, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of complex process, large investment, unstable effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

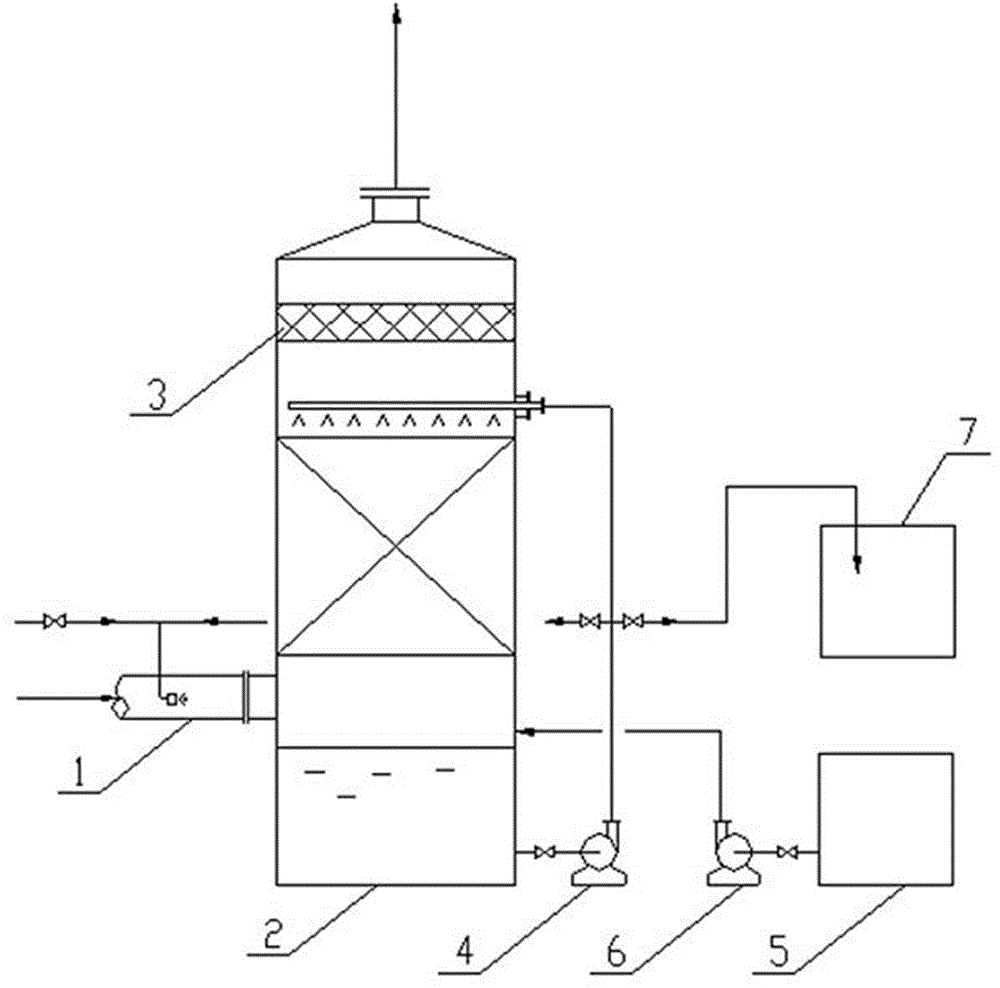

[0008] For better illustration and implementation, the present invention will be described in detail below in conjunction with flow charts and specific examples.

[0009] One set of three-waste mixed-combustion boiler, the combustion components are synthetic ammonia gas blowing gas, ammonia storage tank discharge gas and air release, gas-making slag, coal and other mixed combustion, the boiler evaporation capacity is 35 tons / h, and the flue gas after boiler combustion is 55000Nm 3 / h, containing sulfur dioxide 530mg / Nm 3 , nitrogen oxides 260mg / Nm 3 After being dedusted by the post-furnace dust collector, cooled by the economizer, and dedusted by the electrostatic precipitator, the flue gas temperature is 120°C, first enters the pre-cooler 1, and sprays the cooling liquid through the branch a of the circulation pipeline to cool down to 70°C, and then the flue gas The gas enters the absorber 2, and after the circulating absorption liquid sprayed by the circulating pump 3 absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com