Terrace construction equipment capable of preventing dust pollution

A technology for construction equipment and dust pollution, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of difficult operation, insufficient humanization, complex structure design, etc., to reduce dust pollution and human nature. Good chemical design, good effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

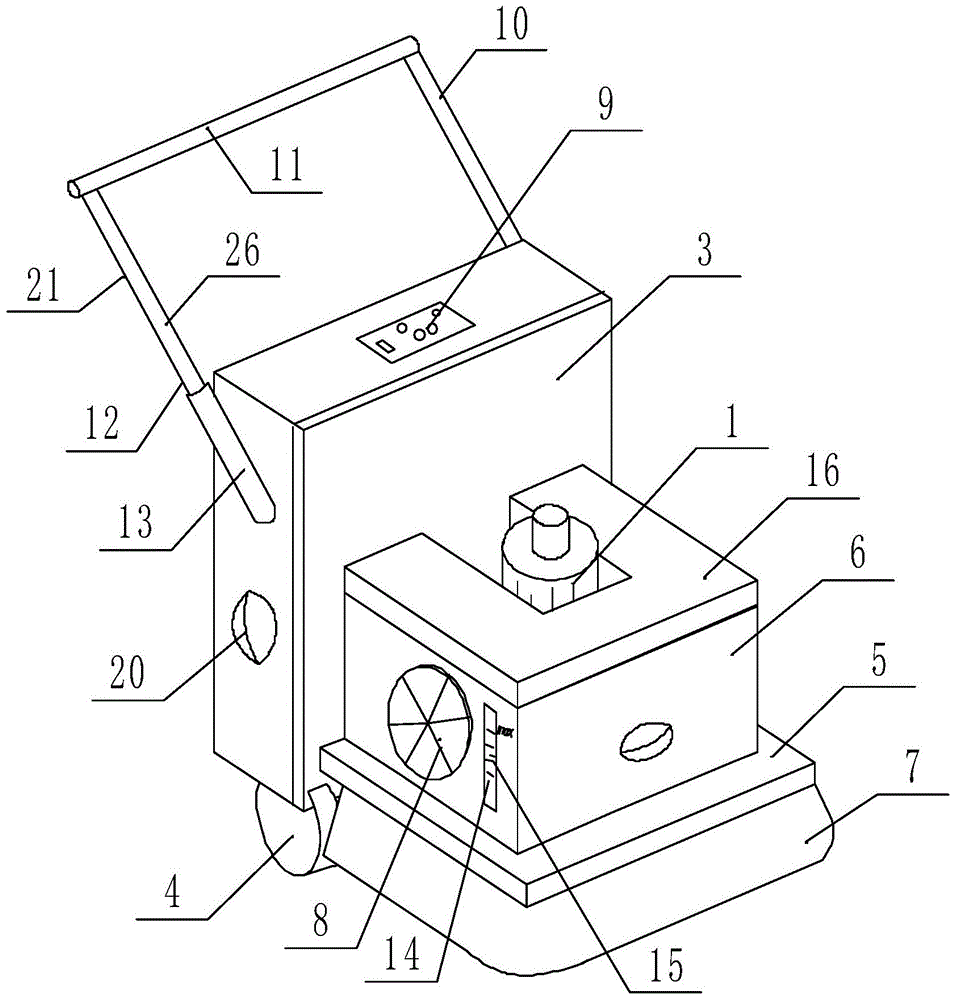

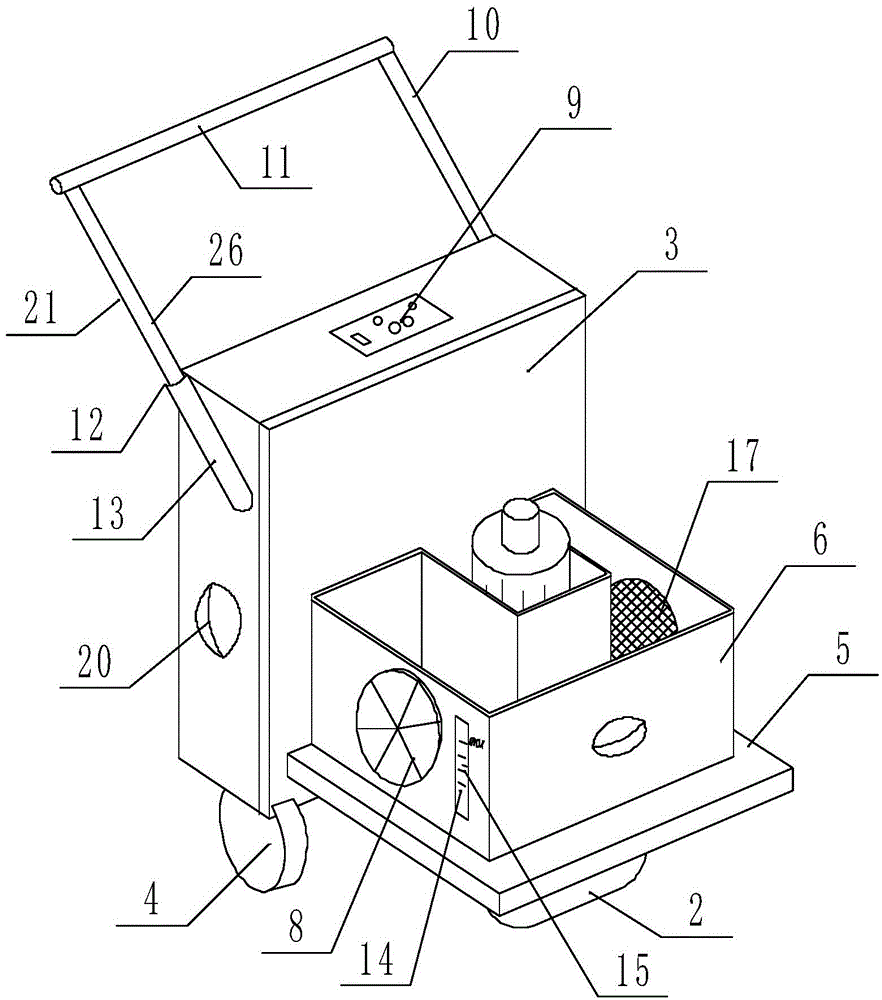

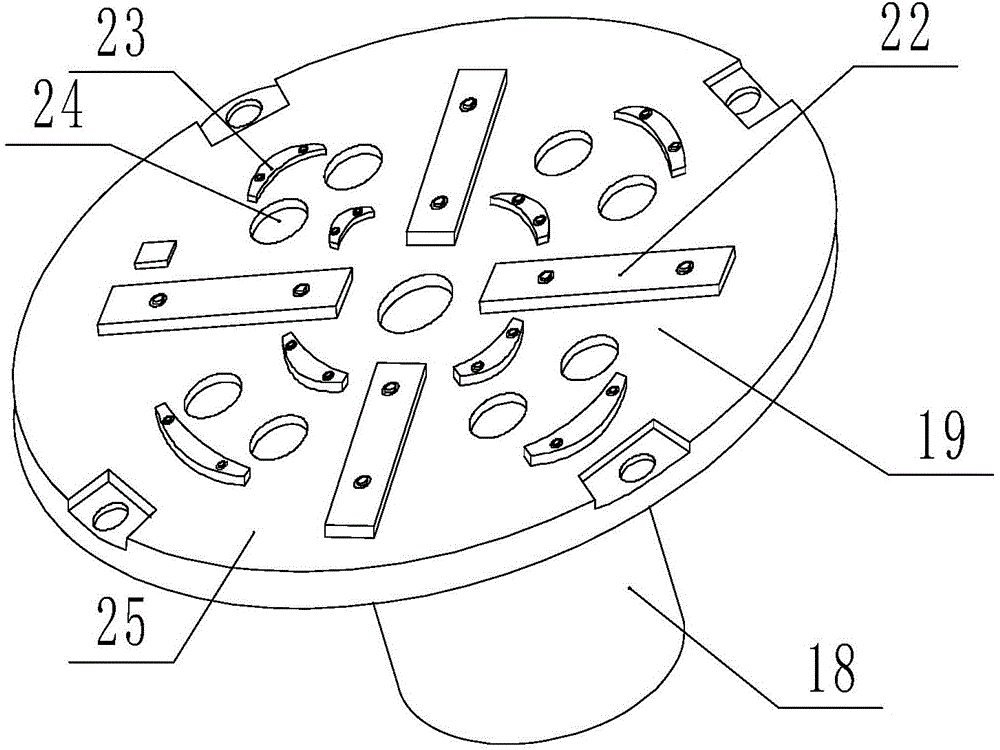

[0027] refer to Figure 1 ~ Figure 3 A floor construction equipment capable of preventing dust pollution, comprising a motor 1, a working head 2, a workbench 3, a walking wheel 4, a base 5, a dust collecting box 6, a dust collecting cover 7 and a fan 8; the working head 2 It includes a fixed seat 18 connected to the output shaft of the motor 1 and a polishing disc 19 installed on the fixed seat 18; the polishing disc 19 includes a grinding block 22, a soil breaking knife 23, a suction hole 24 and a disc-shaped base 25 The grinding block 22 is installed with several evenly distributed along the circumferential direction of the base 25 on the lower end surface of the base 25; at least one earth-breaking knife is arranged between every two grinding blocks 22 on the base 25 23 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com