Pouring mold of precast pre-stressed concrete T-shaped beam

A concrete and prestressed technology, applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of large formwork loss, high labor intensity, and low efficiency, and achieve small maintenance workload, reduce labor intensity, and save time. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

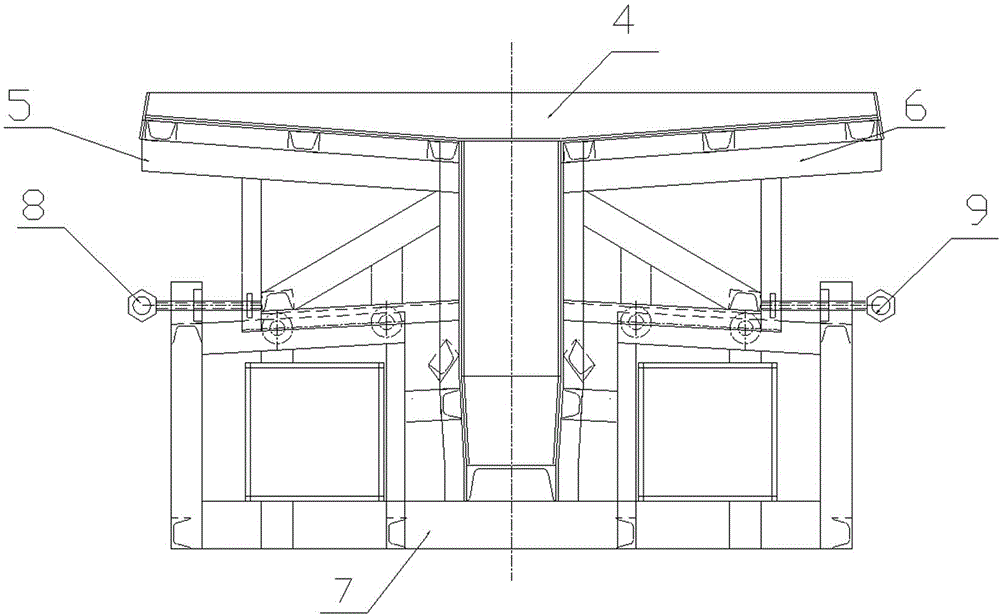

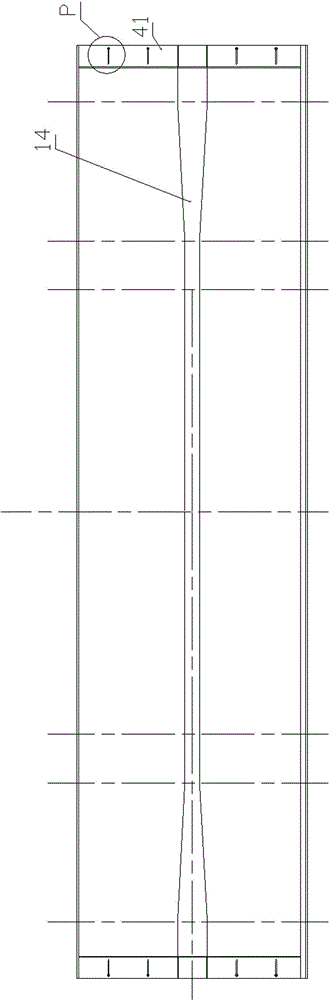

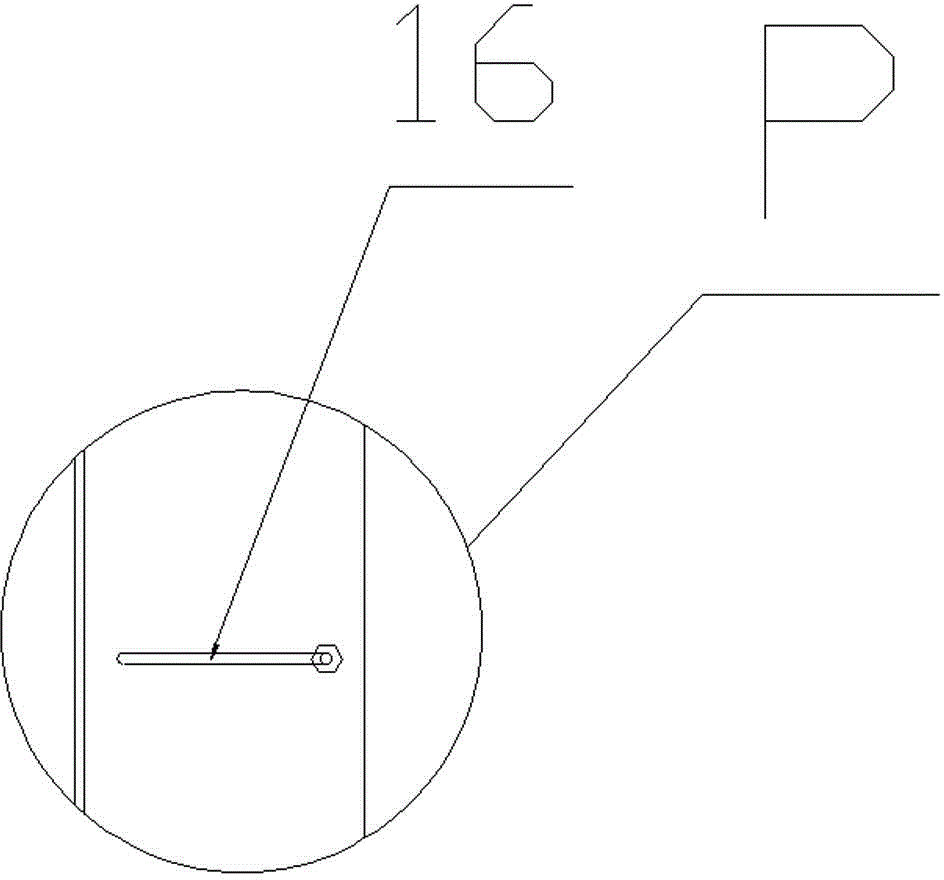

[0032] see Figures 1 to 13 , a casting mold for prefabricated prestressed concrete T-beams, comprising a left formwork 1, a right formwork 2, a bottom formwork 3 and end baffles 4 constituting a T-beam cavity 14. The left formwork 1, right formwork 2, and bottom formwork 3 are all integral formworks with smooth surfaces and no gaps formed by welding several steel plates. The left template 1 is fixed on the left template support frame 5, the right template 2 is fixed on the right template support frame 6, the bottom template 3 is fixed on the bottom template support frame 7, the left template support frame 5, The right template supporting frame 6 is slidingly fitted on the bottom template supporting frame 7 respectively, and is located on the left and right sides of the bottom template 3 . The left formwork support frame 5 and the right formwork support frame 6 are symmetrically arranged on the left and right sides of the bottom formwork 3, and are slidably matched with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com