A kind of Teflon semiconductor thin film for electric wire and cable and preparation method thereof

A technology of wire and cable and Teflon, which is applied in the field of Teflon semiconductor film for wire and cable and its preparation, which can solve the problems of poor flame retardancy and achieve good effect, good flame retardancy and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

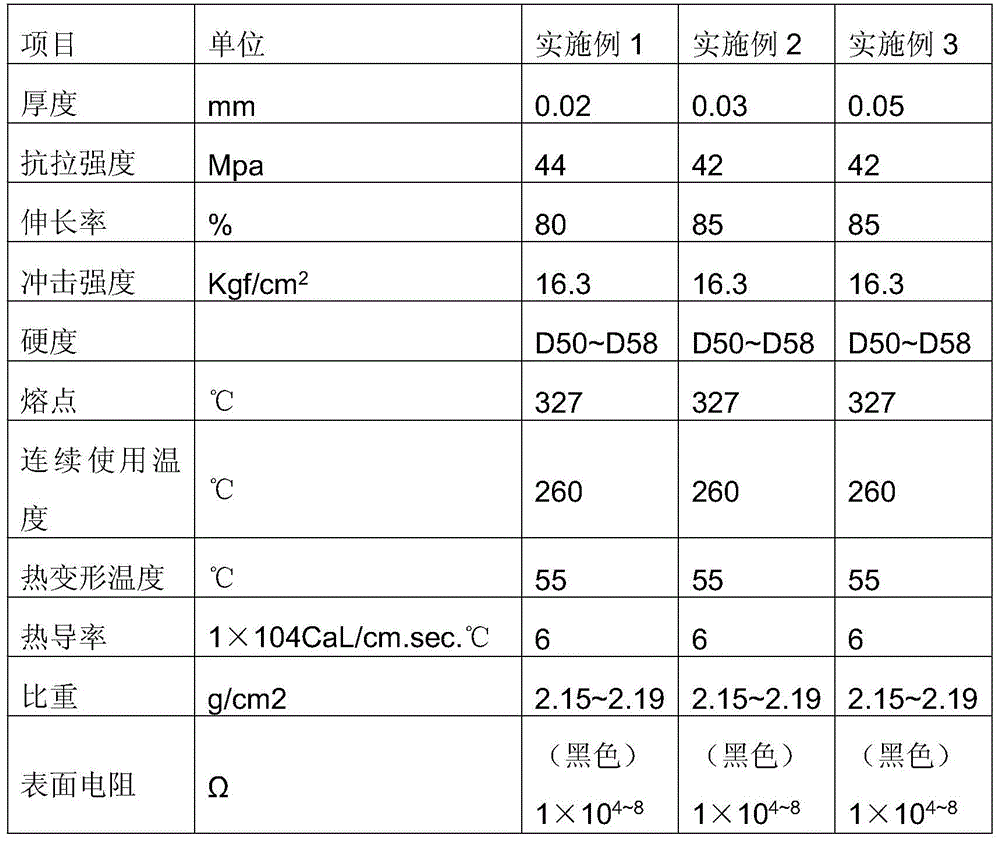

Embodiment 1

[0036] A kind of Teflon semiconducting film for electric wire and cable is prepared according to the following method by polytetrafluoroethylene 98wt% and carbon black 2wt%:

[0037]Take polytetrafluoroethylene and carbon black, the average particle size of polytetrafluoroethylene is 20-35 μm, and the particle size of carbon black is required to be 800-1000 mesh. Using a high-speed mixer, it is mixed evenly through four processes of primary mixing, premixing, high-speed mixing, and sieving, and the mixing process control time is 0.5 to 3 minutes.

[0038] Weigh the well-mixed mixture powder accurately, and add the weighed raw materials evenly into the mold. Put the mold into the middle of the upper and lower platens of the press, calculate the pressure (the pressure calculation formula is: gauge pressure F = product cross-sectional area S / cylinder piston area s × P unit pressure, P = 250 ~ 300kgf), and set the pressure at the same time Program, the pressing speed is general...

Embodiment 2

[0042] The Teflon semiconductor film for wires and cables in this embodiment is made of 92 wt% polytetrafluoroethylene and 8 wt% carbon black, the thickness of the film is 0.03mm, and the preparation operation is the same as that of Example 1.

Embodiment 3

[0044] The Teflon semiconductor film for wires and cables in this embodiment is made of 95 wt% polytetrafluoroethylene and 5 wt% carbon black, the thickness of the film is 0.05 mm, and the preparation operation is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com