PG82-22 modified asphalt and preparation method thereof

A technology of modified asphalt and straight-run asphalt, used in building components, building insulation materials, buildings, etc., can solve the problem that the low temperature ductility damage of modified asphalt is relatively large, it is not conducive to the quality control of other products, and the segregation phenomenon of modified asphalt is aggravated. and other problems, to achieve the effect of improving anti-rutting performance and anti-aging performance, ensuring actual road performance, and avoiding high-temperature thermal oxidation aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: A kind of PG82-22 modified asphalt and preparation method thereof

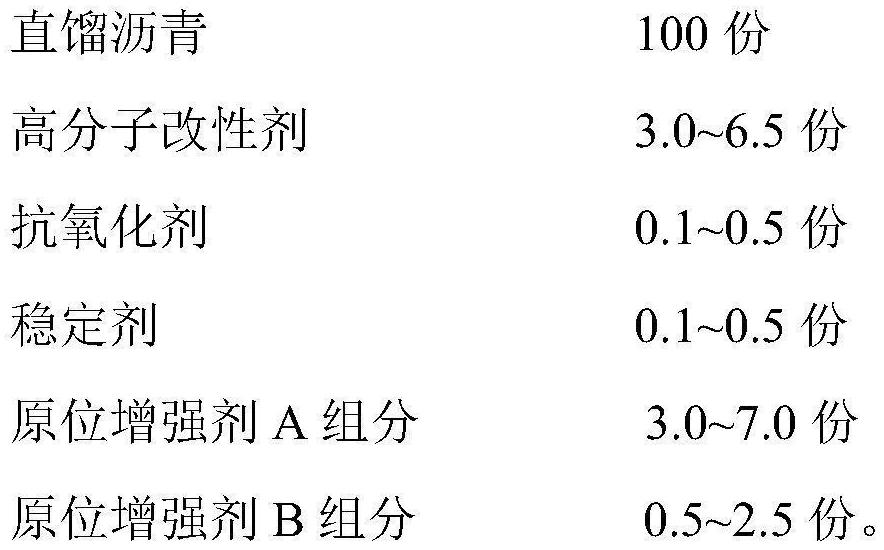

[0043] A kind of PG82-22 modified asphalt, calculated according to the parts by mass, includes the following components:

[0044]

[0045] A preparation method of PG82-22 modified asphalt, comprising the following steps:

[0046] S1: Weigh 65g of linear SBS modifier with a molecular weight of 150,000, 1000g of SK90# base asphalt, 5g of antioxidant (β-(4-hydroxyphenyl-3,5-di-tert-butyl) propionate n-octadecanoate Carbon alcohol ester: triphosphite = 3:2), sulfur stabilizer 1g, lauric acid 60g (0.3mmol / kg), ursi D10g (0.1mmol / kg);

[0047] S2: After heating SK90# base asphalt to 160°C, add SBS modifier, shear at a speed of 3000r / min for 1.0h, and stir for 2h;

[0048] S3: Add lauric acid, n-octadecyl β-(4-hydroxyphenyl-3,5-di-tert-butyl)propionate and triphosphite, and stir at 180°C for 1.5h;

[0049] S4: add sulfur stabilizer, stir at 180°C for 5 hours to obtain modified asphalt;

[...

Embodiment 2

[0052] Embodiment 2: A kind of PG82-22 modified asphalt and its preparation method

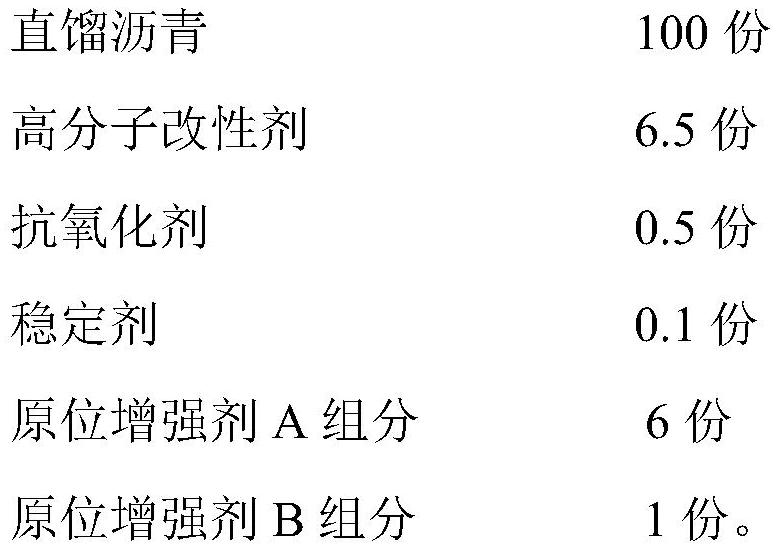

[0053] A kind of PG82-22 modified asphalt, calculated according to the parts by mass, includes the following components:

[0054]

[0055]

[0056] A preparation method of PG82-22 modified asphalt, comprising the following steps:

[0057] S1: Weigh 30g of linear SBS modifier with a molecular weight of 150,000, 1000g of Xitai 70# base asphalt, 1.8g of antioxidant (β-(4-hydroxyphenyl-3,5-di-tert-butyl) propionic acid N-octadecyl alcohol ester: triphosphite = 1:0.8), sulfur stabilizer 2g, lauric acid 40g (0.2mmol / kg), Wuersi D10g (0.1mmol / kg);

[0058] S2: After heating Xitai 70# base asphalt to 180°C, add SBS modifier, shear at a speed of 5000r / min for 1.0h, and stir for 2h;

[0059] S3: Add lauric acid, n-octadecyl β-(4-hydroxyphenyl-3,5-di-tert-butyl)propionate and triphosphite, and stir at 180°C for 1.5h;

[0060] S4: add sulfur stabilizer, stir at 180°C for 5 hours to obtain modifie...

Embodiment 3

[0063] Embodiment 3: A kind of PG82-22 modified asphalt and its preparation method

[0064] A kind of PG82-22 modified asphalt, calculated according to the parts by mass, includes the following components:

[0065]

[0066] A preparation method of PG82-22 modified asphalt, comprising the following steps:

[0067] S1: Weigh 55g of linear SBS modifier with a molecular weight of 100,000, 1000g of straight-run asphalt (SK90# base asphalt: CNOOC 50# base asphalt=1:1), 3.5g of antioxidant (four (β-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester: triphosphite = 4:3), sulfur stabilizer 2g, stearic acid 70g (0.25mmol / kg), Wuersi D10g (0.1 mmol / kg);

[0068] S2: After heating straight-run asphalt to 175°C, add SBS modifier, shear at a speed of 4000r / min for 1.0h, and stir for 1.5h;

[0069] S3: Add stearic acid, tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate) pentaerythritol ester and triphosphite, and stir at 175° C. for 1.0 h;

[0070] S4: add s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com