Graphene heat-conducting silica gel sheet and preparation method thereof

A technology of thermally conductive silica gel sheet and thermally conductive silica gel, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of small application range of graphene sheets, and achieve the effect of simple manufacturing method, easy operation and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a graphene thermally conductive silica gel sheet, comprising the following steps:

[0024] Step 1: dissolving graphene oxide in distilled water to prepare a graphene oxide aqueous solution of 0.1wt% to 1.5wt%;

[0025] Step 2: The graphene oxide aqueous solution is coated on the heating plate to form a layer of 1-2 mm film. After the film loses 40wt% to 50wt% of water and falls off the heating plate, a bundle of carbon fiber bundles is used as a rolling rod to roll it. Rolled into a roll to obtain a graphene oxide roll, and dried in an oven;

[0026] Step 3: carbonize the graphene oxide roll first, and then graphitize it to obtain a density of 0.1 to 0.2 g / cm 3 Graphene roll film;

[0027] Step 4: Cut the graphene roll film into graphene sheets with a thickness of not less than 0.3mm;

[0028] Step 5: configure a thermally conductive silica gel solution; vacuum mix A / B two-component silica gel, and obtain a thermally conductive silica gel solu...

Embodiment 1

[0061] A preparation method for a graphene thermally conductive silica gel sheet, comprising the following steps:

[0062] Step 1: Dissolve 5.18g of graphene oxide with a solid content of 38.6% in 194.82g of distilled water, and combine with ultrasonic stirring for 2h to prepare a 1wt% graphene oxide aqueous solution;

[0063] Step 2: Coat the graphene oxide aqueous solution on the heating plate to form a film of 1-2mm, and set the temperature of the heating plate to 80°C to dehydrate the film; when the film loses 40wt% of water and falls off the heating plate, Use a bundle of carbon fiber bundles as a rolling rod to roll it into a roll to obtain a graphene oxide roll. The gap between layers of the graphene oxide roll is less than 1mm, and dry it in an oven at 80°C for 2 to 4 hours;

[0064] Step 3: Carbonize graphene oxide rolls in graphene rolls in a tube furnace, and the heating rate of the tube furnace is divided into three stages:

[0065] The first stage: keep graphene ...

Embodiment 2

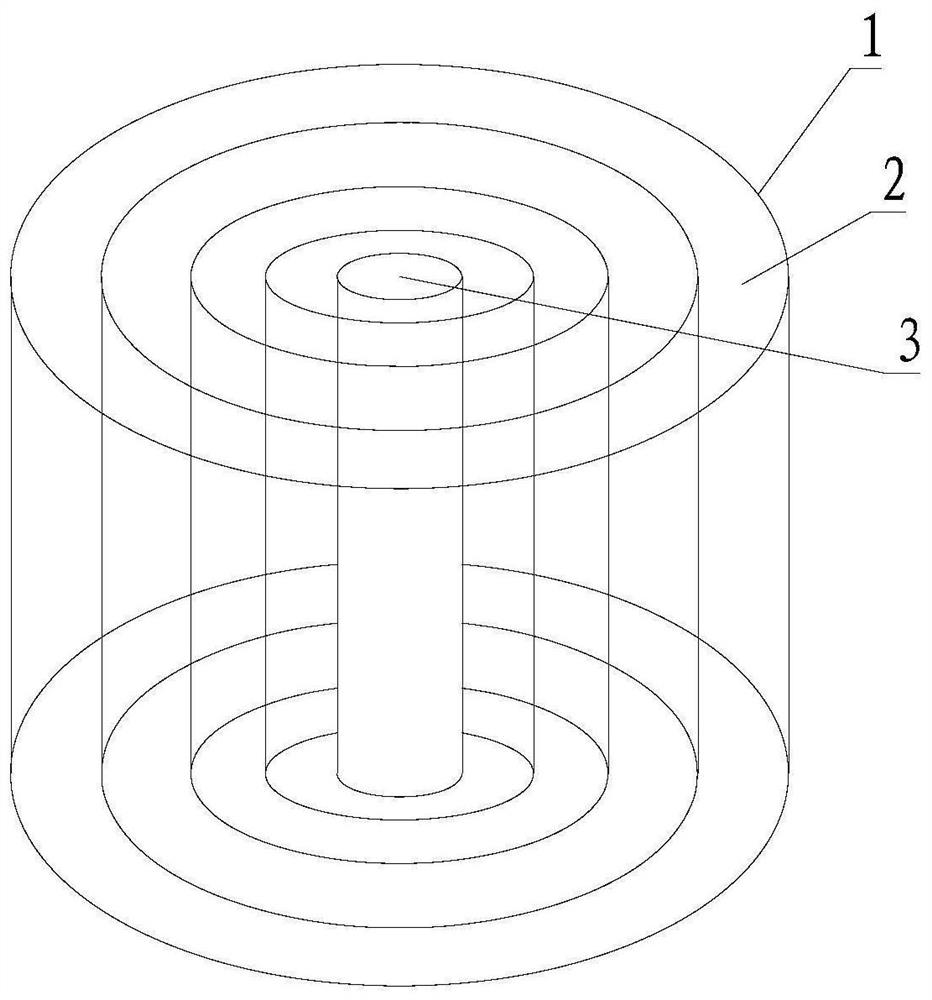

[0073] refer to figure 1 , on the basis of Example 1, a graphene heat-conducting silica gel sheet is made, including graphene roll 1, heat-conducting silica gel 2 and carbon fiber bundle 3; graphene roll 1 is wound on the outside of carbon fiber bundle 3; heat-conducting silica gel 2 is bonded On the surface of the graphene roll 1 after tiling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com