Etching solution composition for copper layer and titanium layer and method of preparing array substrate for liquid crystal display using the same

A composition and etchant technology, applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of glass substrate and silicon layer damage, unoptimized application, poor etching profile, etc., to reduce the degree of heat generation and improve Productivity, effects of excellent etching properties

Active Publication Date: 2015-09-16

DONGWOO FINE CHEM CO LTD

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this case, however, the etch profile is poor and post-processing is difficult

In particular, fluoride ions (F - ) can cause damage to glass substrates and silicon layers, therefore, it is not preferred for practical processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0091] An etchant composition (unit: wt.%) was prepared by using the constituent components listed in Table 1 below.

[0092] [Table 1]

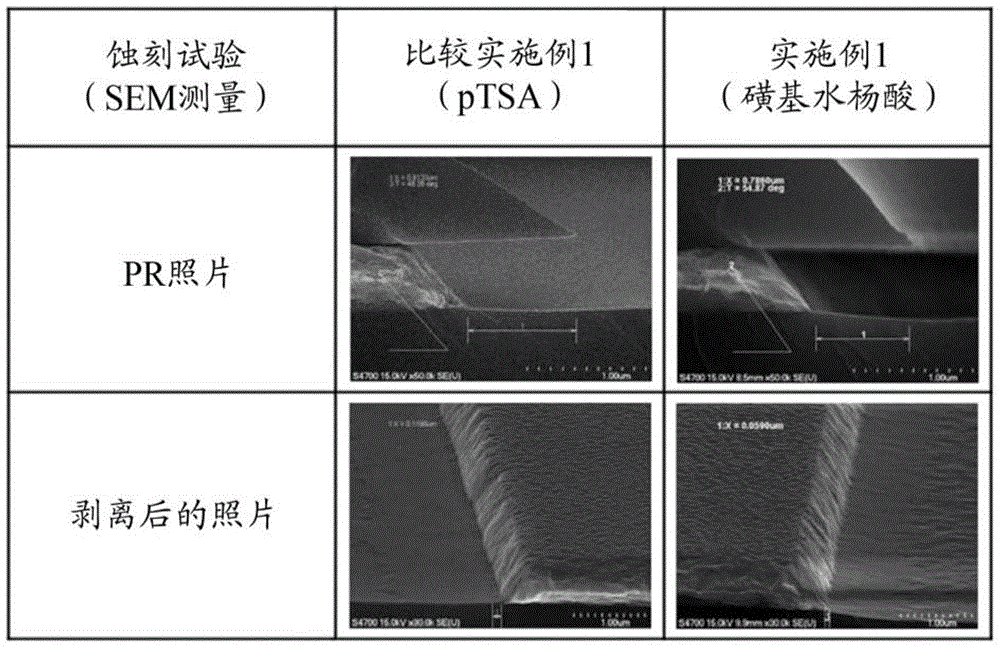

[0093]

[0094]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an etching solution composition for a copper layer and a titanium layer and a method of preparing an array substrate for a liquid crystal display using the same. The etching solution composition comprises persulphate and sulfosalicylic acid, so that the multiple metallic layers including copper layers and titanium layers can be uniformly etched in at a high speed in an environmental-friendly way. Excellent thermal control performance and time stability are ensured.

Description

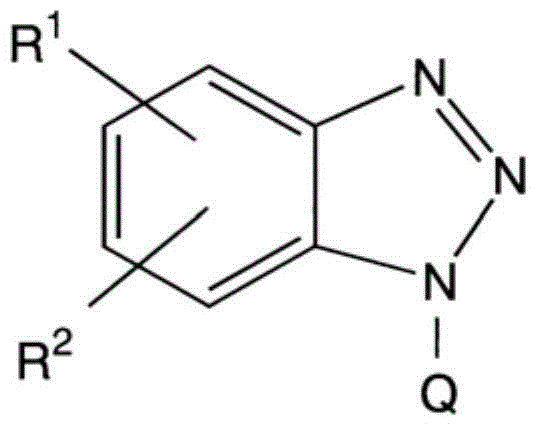

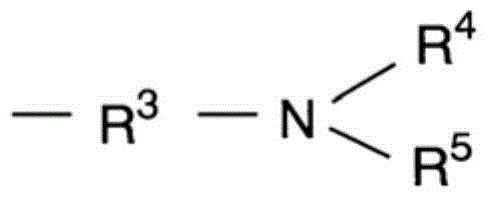

technical field [0001] The invention relates to an etchant composition for a copper layer and a titanium layer, and a method for manufacturing an array substrate of a liquid crystal display using the etchant composition. Background technique [0002] A representative electronic circuit for driving semiconductor devices and flat panel displays is a thin film transistor (TFT). A method of manufacturing a TFT-LCD generally includes forming a metal layer on a substrate as a wire material for a gate electrode and a source / drain electrode, forming a photoresist on a selected area of the metal layer, and then using The photoresist acts as a mask to etch the metal layer. [0003] Conventionally, as the wiring material of the gate electrode and the source / drain electrodes, metal layers in which aluminum or its alloy and other metals are sequentially laminated have been used. Aluminum is cheaper and has low electrical resistance, but has poor chemical resistance and can cause prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/18C23F1/26

CPCC23F1/18C23F1/44G02F1/136286G02F1/136295

Inventor 刘仁浩鞠仁说

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com