Pile soil interface shear simulation tester of opened concrete pipe pile

A technology of concrete pipe pile and pile-soil interface, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of affecting the test results, no longer applicable, obvious size effect, etc., and achieve accurate test results and convenient operation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

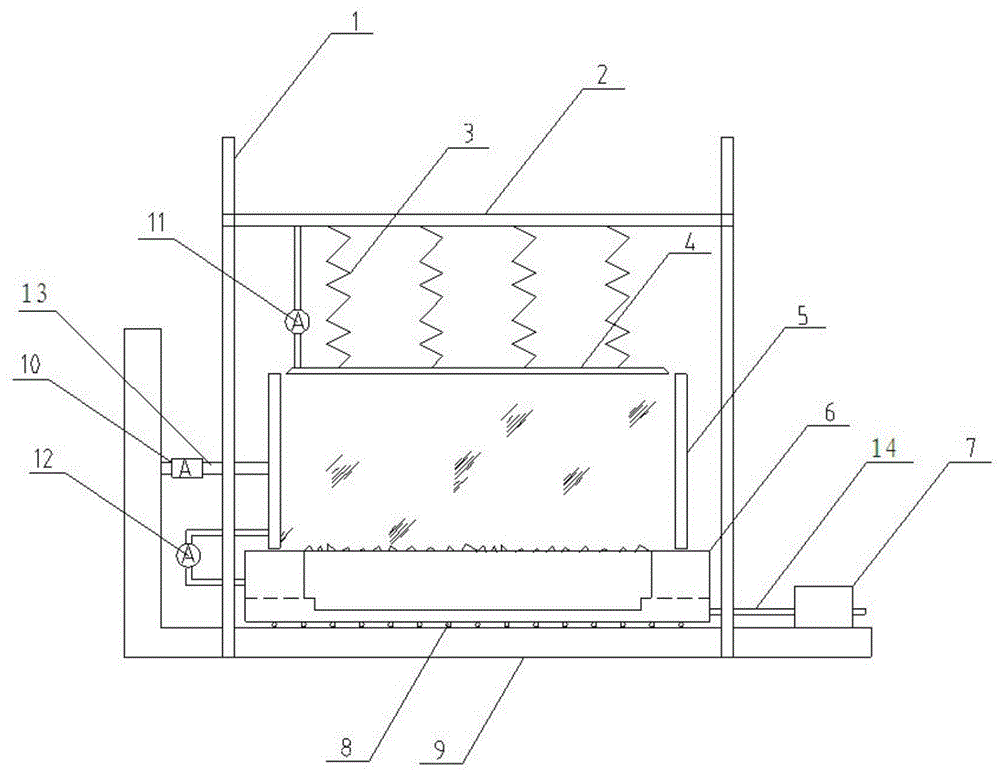

[0015] The main structure of the open concrete pipe pile pile-soil interface shear simulation test device described in this embodiment includes a screw rod 1, a detachable spring upper fixing plate 2, a spring 3, a detachable spring lower fixing plate 4, an upper shear box 5, Lower shear box 6, operating platform 9, roller 8, numerical control motor 7, lateral displacement sensor 12, vertical displacement sensor 11, load sensor 10, first steel rod 13 and second steel rod 14, wherein screw rod 1, can Removing the spring upper fixing plate 2, spring 3 and detachable spring lower fixing plate 4 constitutes a constant stiffness spring dynamic loading system, the upper shear box 5 and the lower shear box 6 constitute a visual pile-soil interface shear simulation system, the operating platform 9, The roller 8 and the numerical control motor 7 form a two-way transmission system of the roller, and the lateral displacement sensor 12, the vertical displacement sensor 11 and the load sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com