Hydraulic support frame data collecting method, hydraulic support frame data collecting system and hydraulic support frame centralized control system

A technology of data acquisition system and hydraulic support, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of inability to obtain support information data in time, time-consuming support information data, low mining efficiency, etc., to improve automation The effect of mining efficiency, transmission rate improvement, and operation speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described below in conjunction with the accompanying drawings.

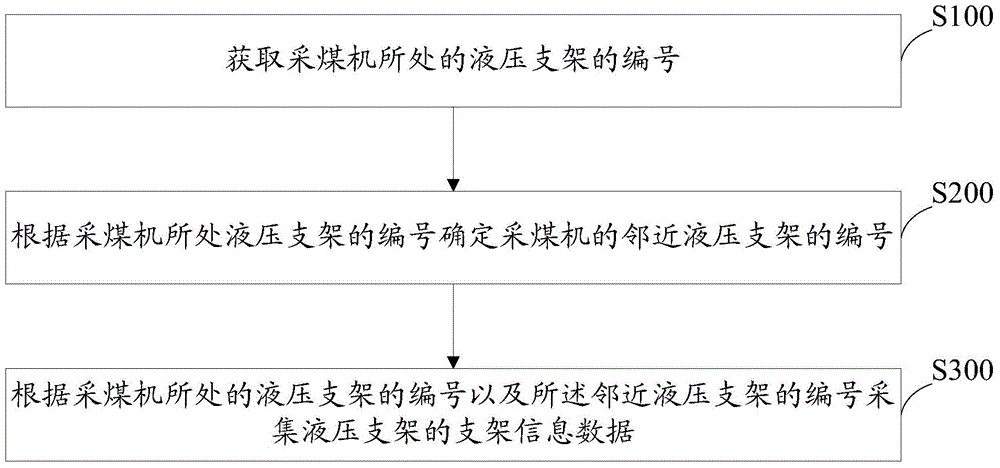

[0024] Such as figure 1 As shown, this embodiment provides a method for collecting data of a hydraulic support, including the following steps:

[0025] S100 obtains the number of the hydraulic support where the shearer is located;

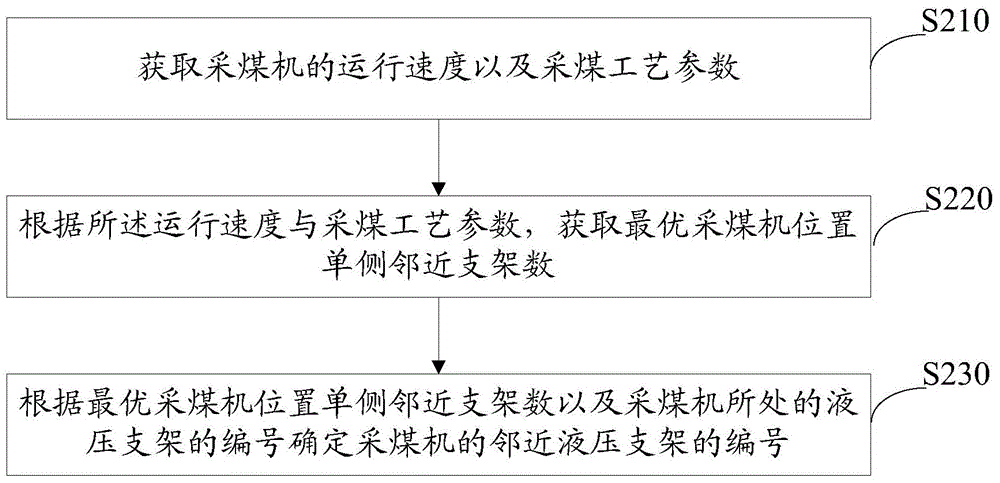

[0026] S200 determines the number of the hydraulic support adjacent to the shearer according to the number of the hydraulic support where the shearer is located;

[0027] S300 collects support information data of the hydraulic support according to the number of the hydraulic support where the shearer is located and the number of the adjacent hydraulic support.

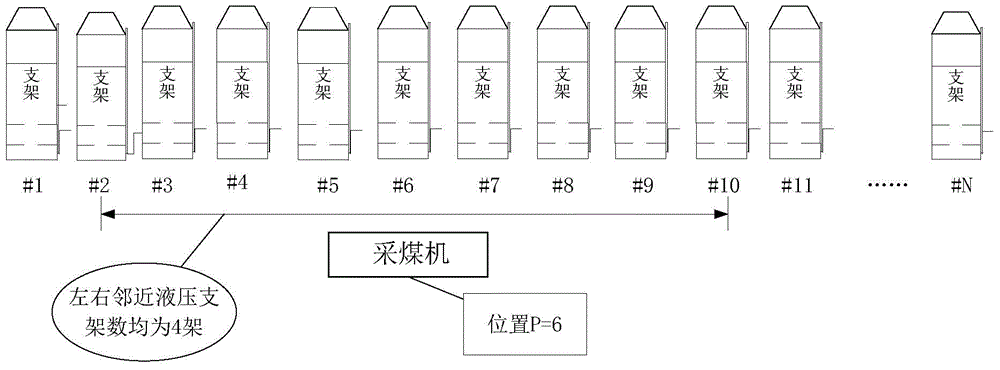

[0028] Specifically, each hydraulic support in the fully mechanized mining face has its corresponding number, and the hydraulic supports are arranged along the fully mechanized mining face in the order of numbering. In the process of automated mining, the fully mechanized mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com