Flange protective cover

A protective cover and flange technology, applied in the field of flange protective covers, can solve the problems of poor safety protection such as anti-corrosion and waterproof, poor air tightness of the protective cover, and difficult disassembly and assembly, etc., to achieve good sealing, simple structure, and easy disassembly. The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but not intended to limit the present invention.

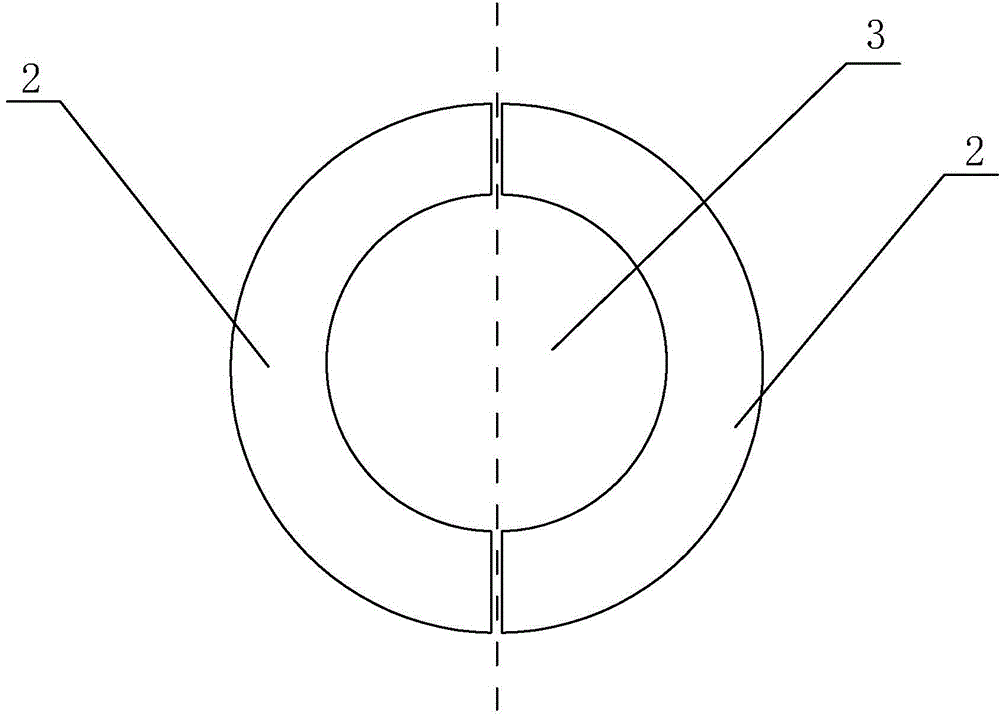

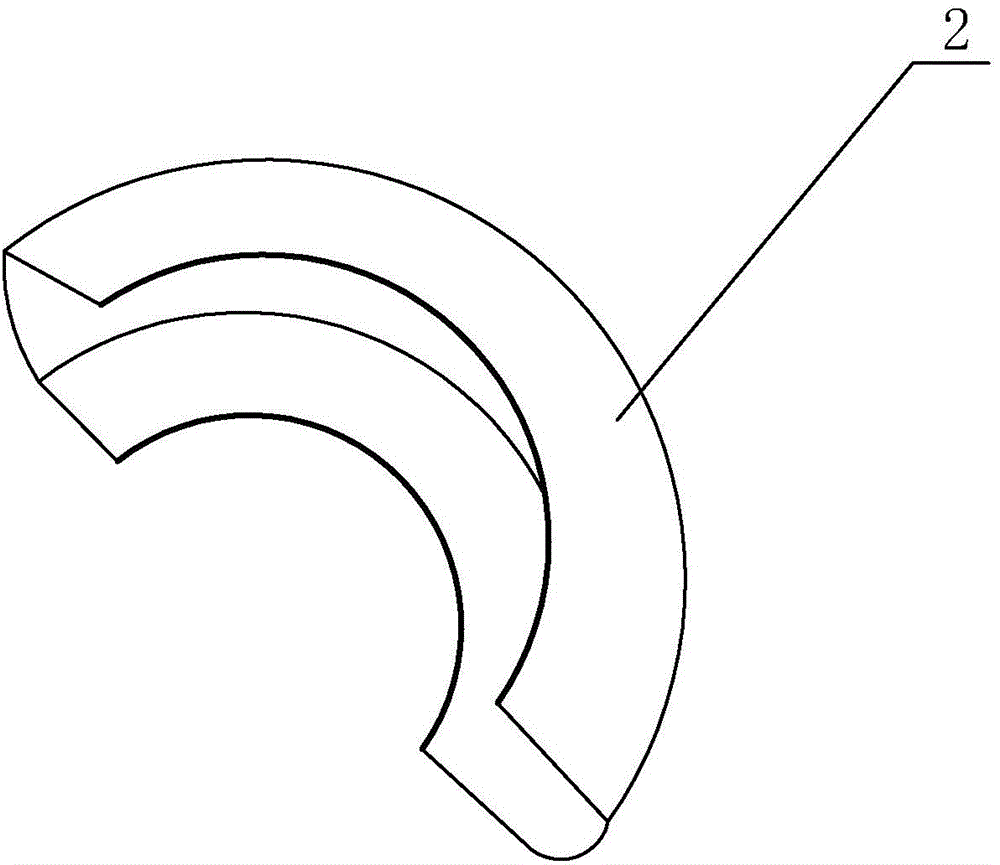

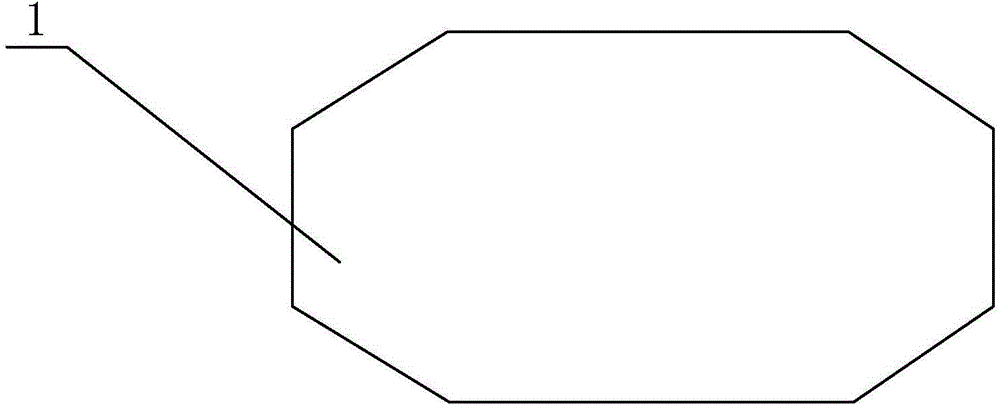

[0024] Such as figure 1 , figure 2 As shown, a flange protection cover includes a closed cover body 1 with a hollow inside, and two circular holes 3 for the pipeline 4 to pass through are opened on the cover body 1, and along the direction where the circular holes 3 are located The central axis divides the cover body 1 into two matching half-disks 2, and the two matching half-discs 2 are movably connected so that the two half-discs 2 can be separated from each other. The cover body 1 is a hard shell , the diameter of the circular hole 3 should be slightly larger than the diameter of the installed pipeline 4, so that the pipeline 4 can pass through the circular hole 3; A soft sealing strip is provided at the contact point, one end of the soft sealing strip is fixed on the cover body 1 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com