Phased array quantitative damage monitoring method, phased array quantitative damage monitoring device and phased array quantitative damage monitoring system

A damage monitoring and phased array technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as difficulty in signal analysis and interpretation, consistent initial phase of wave packets, and distortion of beamforming signal waveforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

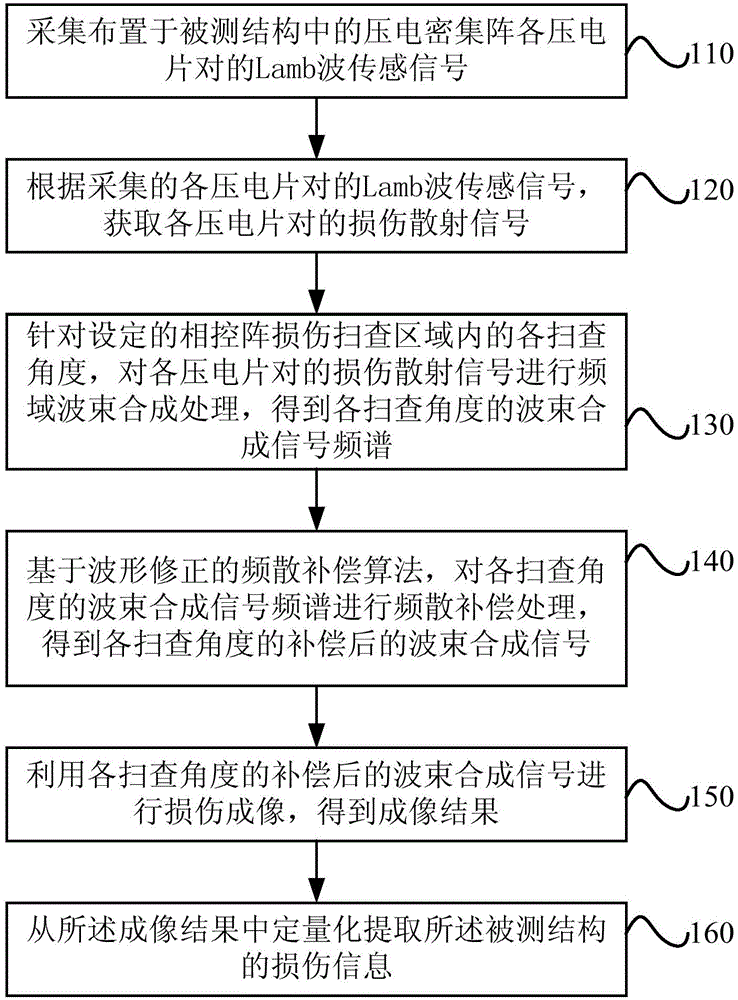

[0047] see figure 1 , is a schematic flowchart of a phased array quantitative damage monitoring method provided in Embodiment 1 of the present invention. The method of the embodiment of the present invention can be executed by a phased array quantitative damage monitoring device configured with hardware and / or software, and the implementation device can be configured to include a piezoelectric dense array corresponding to the structure under test and signal generation and acquisition. In the phased array quantitative damage monitoring system of the device.

[0048]Taking the phased array quantitative monitoring of cracks in the aluminum plate structure as an example, the method of the embodiment of the present invention will be described. However, the structure to be tested in this embodiment is not limited to the aluminum plate structure in the example.

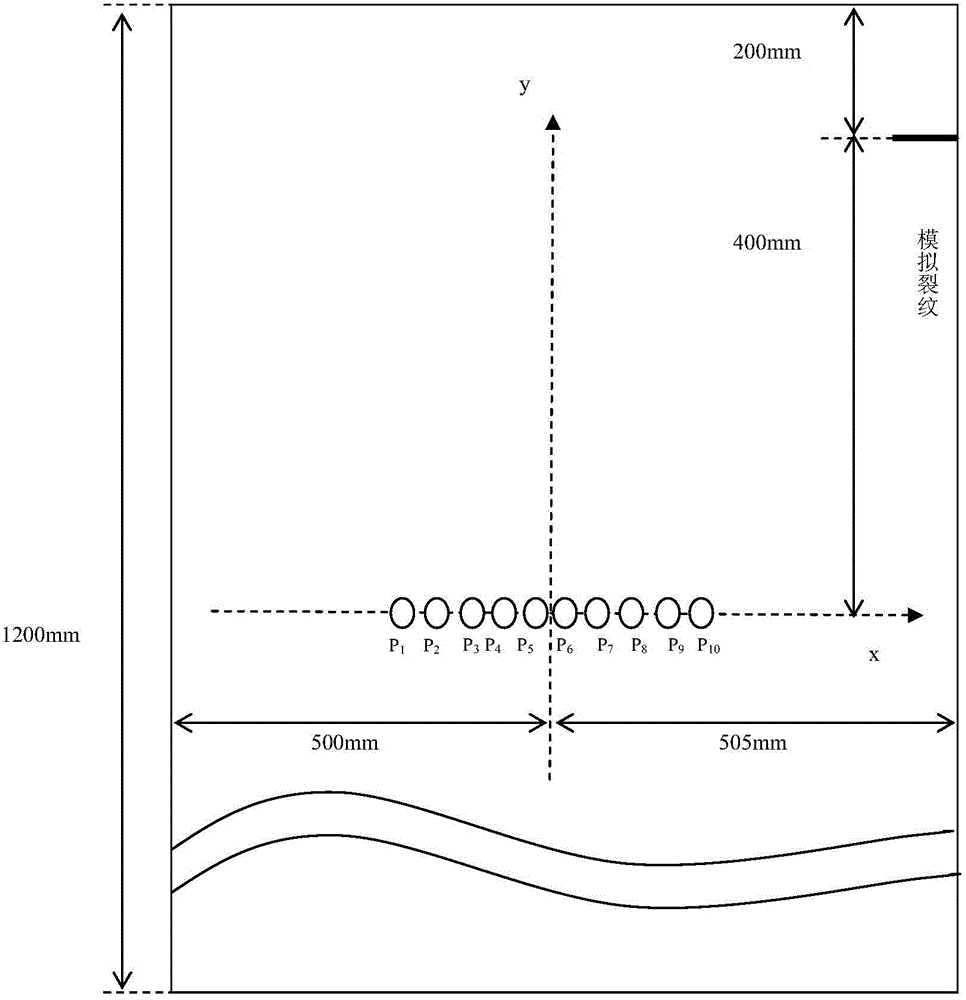

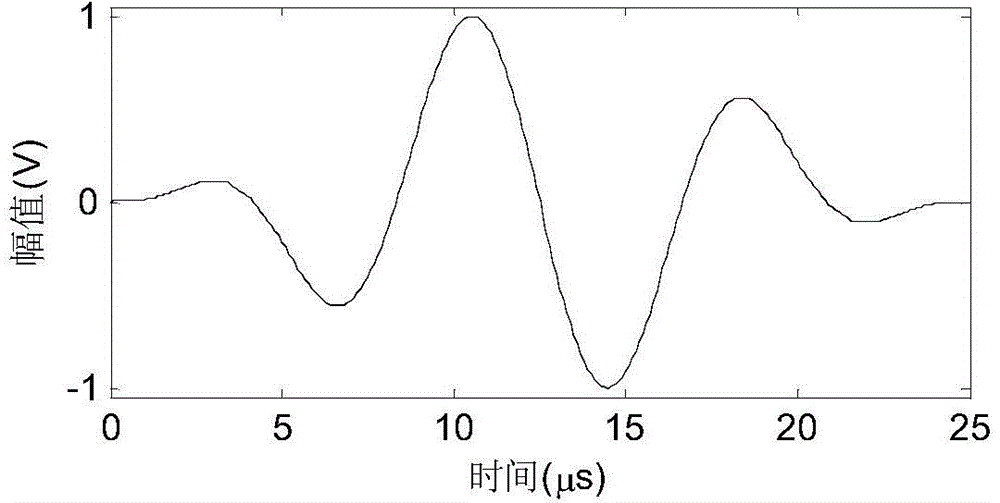

[0049] Firstly, the tested structure is introduced. It is a 2024 aluminum plate structure commonly used in aircraft, wit...

Embodiment 2

[0104] see Figure 15 , is a schematic structural diagram of a phased array quantitative damage monitoring device provided in Embodiment 2 of the present invention. The device includes: a signal acquisition module 210 , a beam synthesis processing module 220 and a damage identification module 230 .

[0105] Wherein, the signal collection module 210 is used to collect the Lamb wave sensing signals of each pair of piezoelectric sheets of the piezoelectric ensemble arranged in the structure under test.

[0106] Specifically, the signal acquisition module 210 can realize the acquisition of Lamb wave sensing signals through the piezoelectric dense array corresponding to the signal generator and the structure under test. That is, through the signal generation and acquisition device, an excitation signal is applied to the piezoelectric sheet as the exciter in the pair of piezoelectric sheets contained in the piezoelectric ensemble corresponding to the structure under test, and each ...

Embodiment 3

[0141] see Figure 16 , is a schematic structural diagram of a phased array quantitative damage monitoring system provided in Embodiment 3 of the present invention. The system includes: a piezoelectric dense array 310 and a signal generator and collector 320 corresponding to the structure to be tested, and also includes: a phased array quantitative damage monitoring device 330 provided by any embodiment of the present invention.

[0142] Specifically, the phased array quantitative damage monitoring device 330 can collect the Lamb wave of each piezoelectric sheet pair of the piezoelectric ensemble arranged in the structure under test through the piezoelectric ensemble corresponding to the collector and the structure under test. sensing signal.

[0143] In the above solution, the signal generating and collecting unit 320 may specifically include: a signal generating unit, a power amplifying unit, a multiplexing unit, a signal conditioning unit, and a signal collecting unit.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com