Control system of error measurement and compensation of curve contour

A technology of curve contour and error measurement, applied in general control system, control/regulation system, digital control, etc., can solve the problems of driver and controller contour error, machine tool structure error, poor practicability, etc., and achieve contour error compensation The effect of enhanced capability, strong contour error compensation capability, and strong automatic control capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

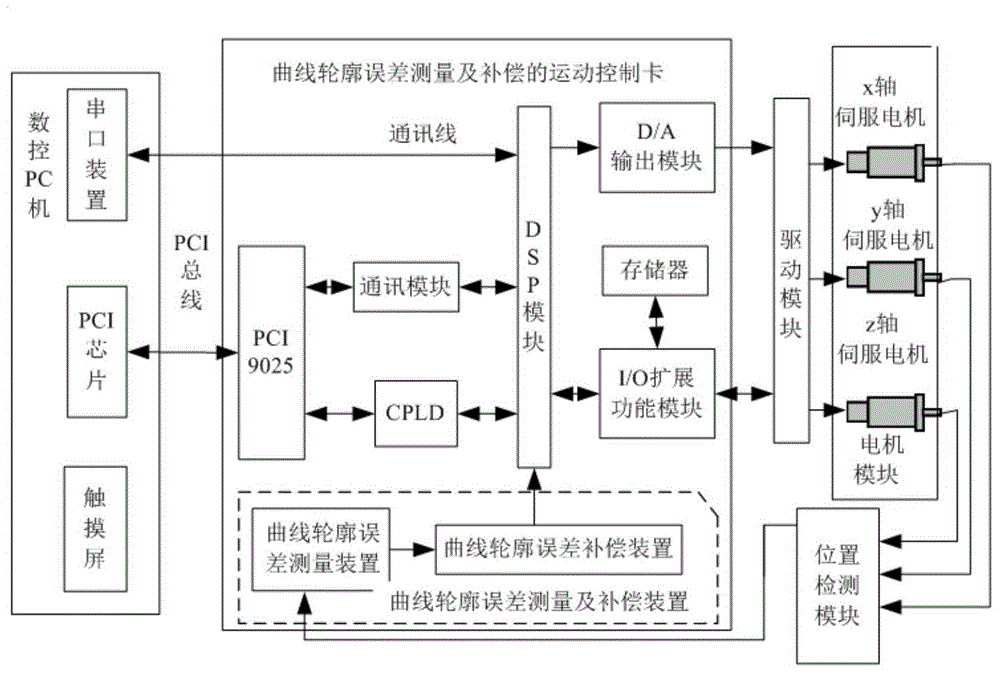

[0053] A control system for curve profile error measurement and compensation provided in this embodiment, such as figure 1 As shown, it includes a CNC PC, a motion control card for measuring and compensating curve contour errors, a drive module, a motor module and a position detection module. Described numerical control PC machine comprises the numerical control PC machine with curve contour error compensation function, serial port device, touch screen and PCI chip; One end is connected with touch screen to realize man-machine dialogue, and the other end is through PCI chip through PCI bus and curve contour error measurement and compensation The motion control card is connected to realize the measurement and compensation of the curve contour error.

[0054] The serial port device includes a serial port device and a serial port circuit; the serial port device is connected with the DSP module in the motion control card for curve profile error measurement and compensation through...

Embodiment 2

[0140] In order to verify the identifiability and correctness of the curve profile error compensation of the present invention, the experimental effect of the present invention is as follows:

[0141] Specifically, such as Figure 11 Shown as a sinusoidal As an example, the interpolation point x∈[0 2π] randomly selects 30 values, and uses the control system for curve contour error measurement and compensation to Perform interpolation to get the theoretical curve and the contour error compensation curve, the curve between the theoretical curve and the contour error compensation curve is the curve contour error, which is determined by Image 6 It can be seen that the curve profile error is less than 0.6 μm, and it can be compensated by the curve profile error compensation method in the processing of small segments; at the same time, the theoretical curve and the profile error compensation curve are similar, but there is a deviation between the theoretical curve and the profil...

Embodiment 3

[0143] The experimental effect that the present invention carries out:

[0144] Set the experimental data of the system simulation, as shown in Table 1; Figure 12 As shown, input a NC program for interpolation, in figure 1 The numerical control simulation interpolation is carried out in the control system of curve profile error measurement and compensation as shown, the simulation diagram is as follows Figure 13 shown.

[0145] Table 1 sets the system simulation parameter values

[0146]

[0147] Specifically, by simulating Figure 13 It can be seen that the space curve simulation is carried out in the curve interpolation contour error measurement and compensation control system using NC program. There are two curves in the figure, which are the original curve and the contour error compensation curve, and the difference between the original curve and the contour error compensation curve. The curve segment sandwiched between is the space curve profile error curve. Obvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com