Photoelectrical composite torsion-resistant medium-voltage wind power cable and method for manufacturing the same

A photoelectric composite and twist-resistant technology, which is applied in the direction of power cables, insulated cables, and communication cables with shielding layers/conductive layers, to achieve the effects of good softness, mechanical damage prevention, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

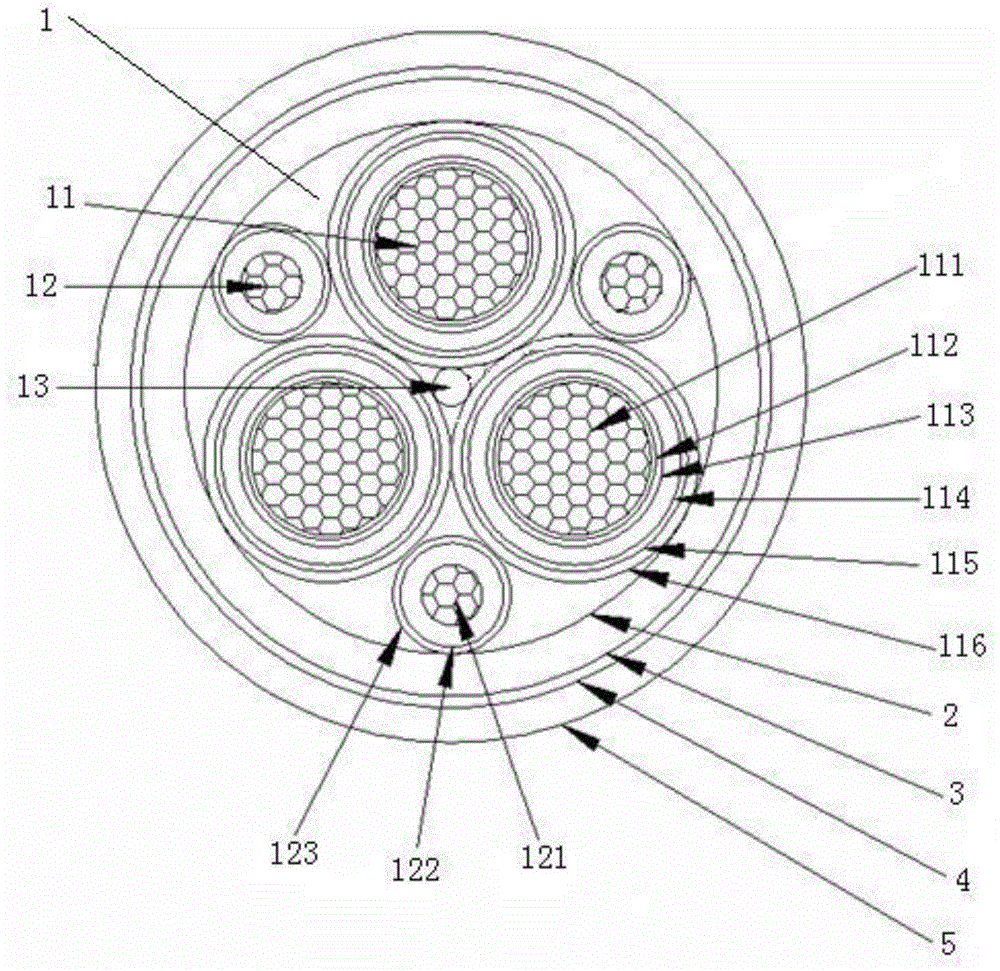

[0046] Such as figure 1 As shown, a photoelectric composite twist-resistant medium-voltage wind energy cable includes a cable core 1, a cable-forming tape layer 2, an inner sheath layer 3, an aramid braid layer 4 and an outer sheath layer 5, and the outer sheath layer 5 of the cable core 1 is The cable wrapping layer 2, the inner sheath layer 3, the aramid fiber braiding layer 4 and the outer sheath layer 5 are covered in sequence.

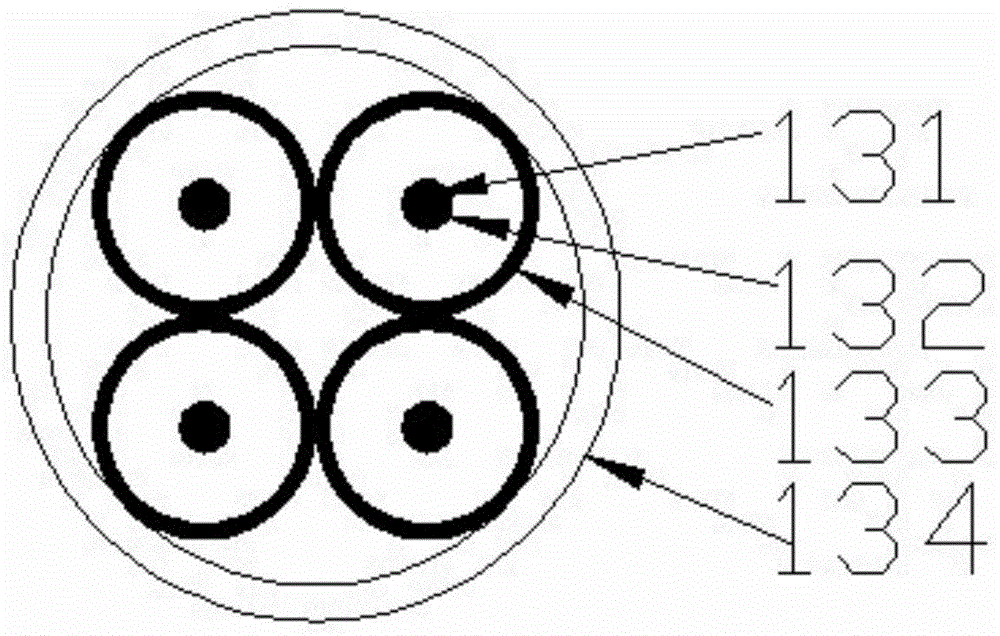

[0047] The cable core 1 is composed of three power transmission cores 11 , three ground cores 12 and an optical fiber unit 13 twisted together.

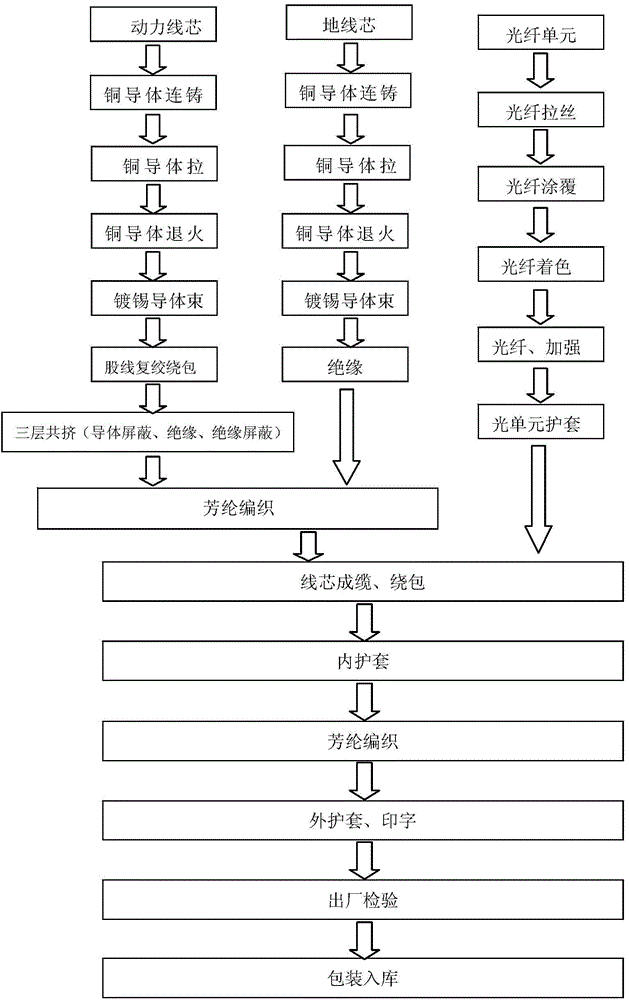

[0048] The power transmission core 11 is composed of a tinned stranded conductor layer 111, a semiconductive tape layer 112, a conductor shielding layer 113, an ethylene-propylene rubber insulating layer 114, an insulating shielding layer 115, and an aramid fiber braiding layer 116; The stranded conductor layer 111 is made by the process of beaming wires in the same direction first and then re-twisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com