Preparation method of air battery cathode catalyst

A cathode catalyst and air battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor crystallinity of crystal materials, poor dispersion of products, poor purity, etc., and achieve high open circuit voltage and strong catalytic activity , the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

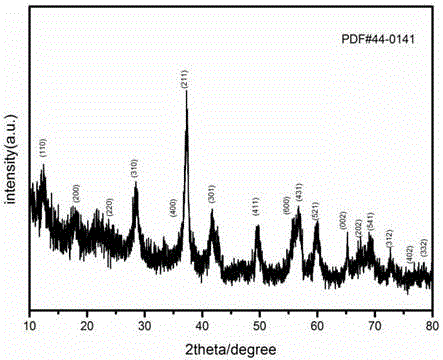

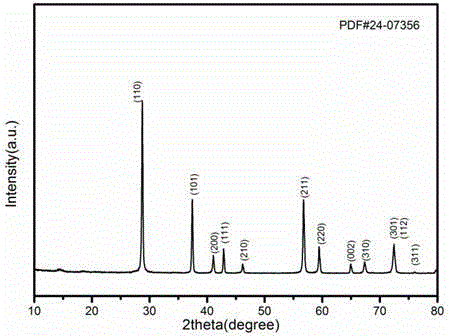

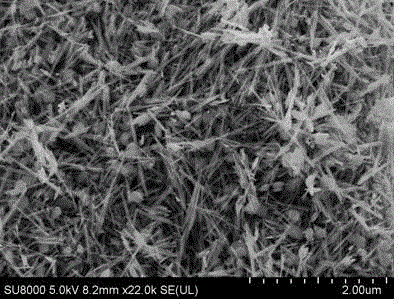

[0028] Weigh 2.7g of potassium permanganate and 110ml of distilled water, and mix evenly under stirring to obtain a purple-black solution; take 8 grams of MnCl 2 4H 2 O add 20ml of water to form an aqueous solution; add the obtained aqueous solution dropwise to the purple-black solution, stir and mix evenly to obtain a suspension; transfer the obtained suspension to a polytetrafluoroethylene-lined stainless steel reaction kettle, After standing for 2 hours, the obtained product is separated into solid and liquid phases; the solid phase is washed with water until there is no ionic component, and Alpha-MnO 2 , the constant temperature standing time of the suspension was changed to 12h, and the prepared Beta-MnO 2; Alpha-MnO 2 with Beta-MnO 2 According to the mass ratio of 3:7 mixed and mechanical ball milled for 2 hours, the final catalyst product was obtained.

Embodiment 2

[0030] Weigh 2.7g of potassium permanganate and 110ml of distilled water, and mix evenly under stirring to obtain a purple-black solution; take 8 grams of manganese nitrate, add 20ml of water to configure an aqueous solution; add the obtained aqueous solution dropwise to the purple-black solution, stir and mix evenly, A suspension was obtained; the suspension was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and stood at 120° C. for 2 h; the obtained product was separated into solid and liquid phases; the solid phase was washed with water until it was free of ionic components. Made Alpha-MnO 2 ; Change the standing time of the suspension at constant temperature to 12h, and the prepared Beta-MnO 2 , the Alpha-MnO 2 with Beta-MnO 2 Mix according to the mass ratio of 3:7 and mechanically ball mill for 2 hours to obtain the final catalyst product.

Embodiment 3

[0032] Weigh 2.7g of potassium permanganate and 110ml of distilled water, and mix evenly under stirring to obtain a purple-black solution; take 8 grams of manganese acetate and add 20ml of water to configure an aqueous solution; the resulting aqueous solution is added dropwise to the purple-black solution, stirred and mixed evenly to obtain Suspension; the suspension was transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle, and stood at 120°C for 2 hours; the obtained product was separated into solid and liquid phases; the solid phase was washed with water until it was free of ionic components. Made Alpha-MnO 2 ; The constant temperature standing time of the suspension was changed to 12h, and the prepared Beta-MnO 2 ; Alpha-MnO 2 with Beta-MnO 2 Mixed by mass ratio 3:7 and mechanically ball milled for 2h to obtain the final catalyst product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com