A High Gain Horn Antenna Based on Metamaterial Loading

A horn antenna and metamaterial technology, applied in the directions of antennas, electrical components, radiating components, etc., can solve the problems of difficulty in analyzing the coupling characteristics of each layer structure, large processing errors of the three-layer transmission surface, and long design cycle, and achieve the goal of preparing The effect of short period, improved radiation gain and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

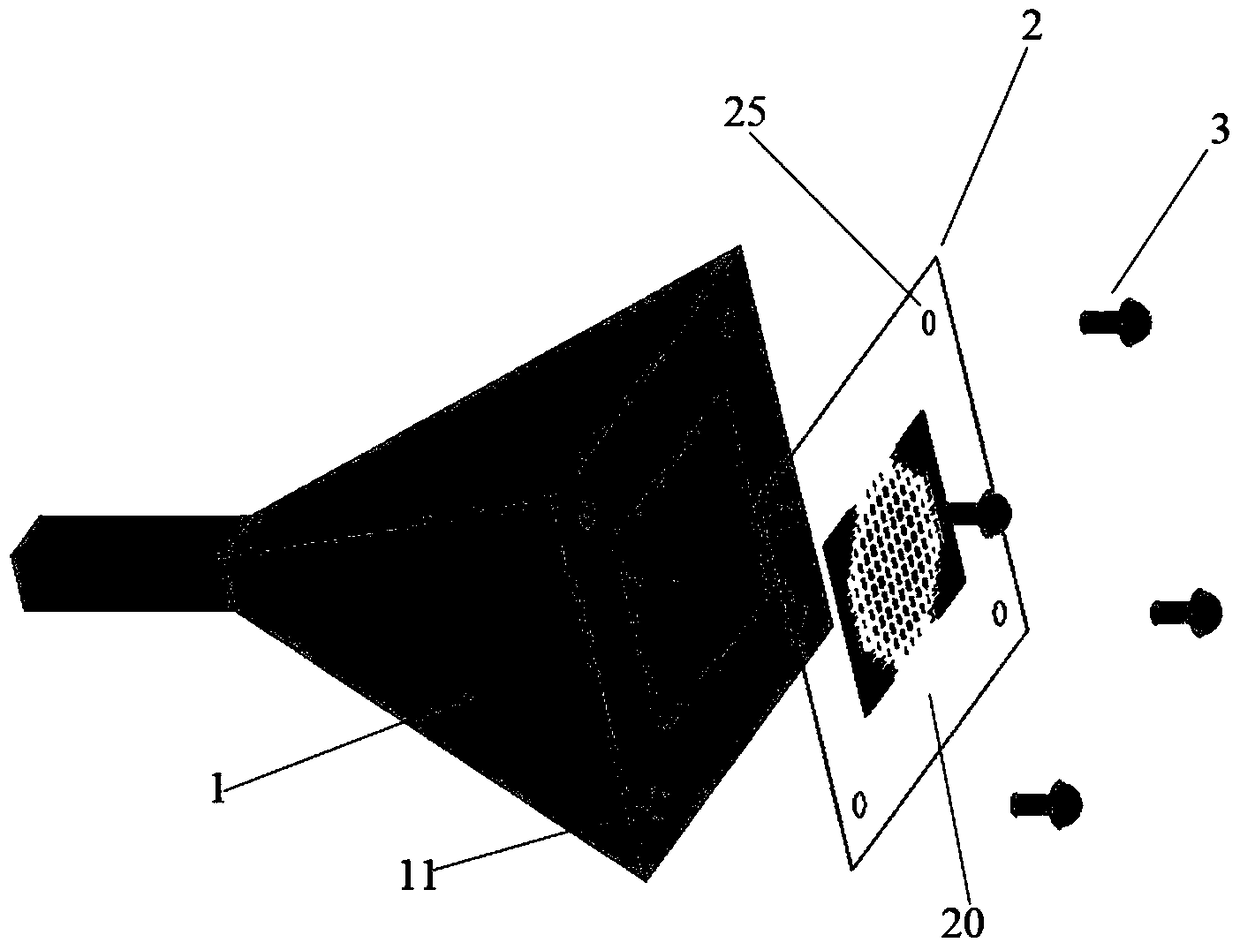

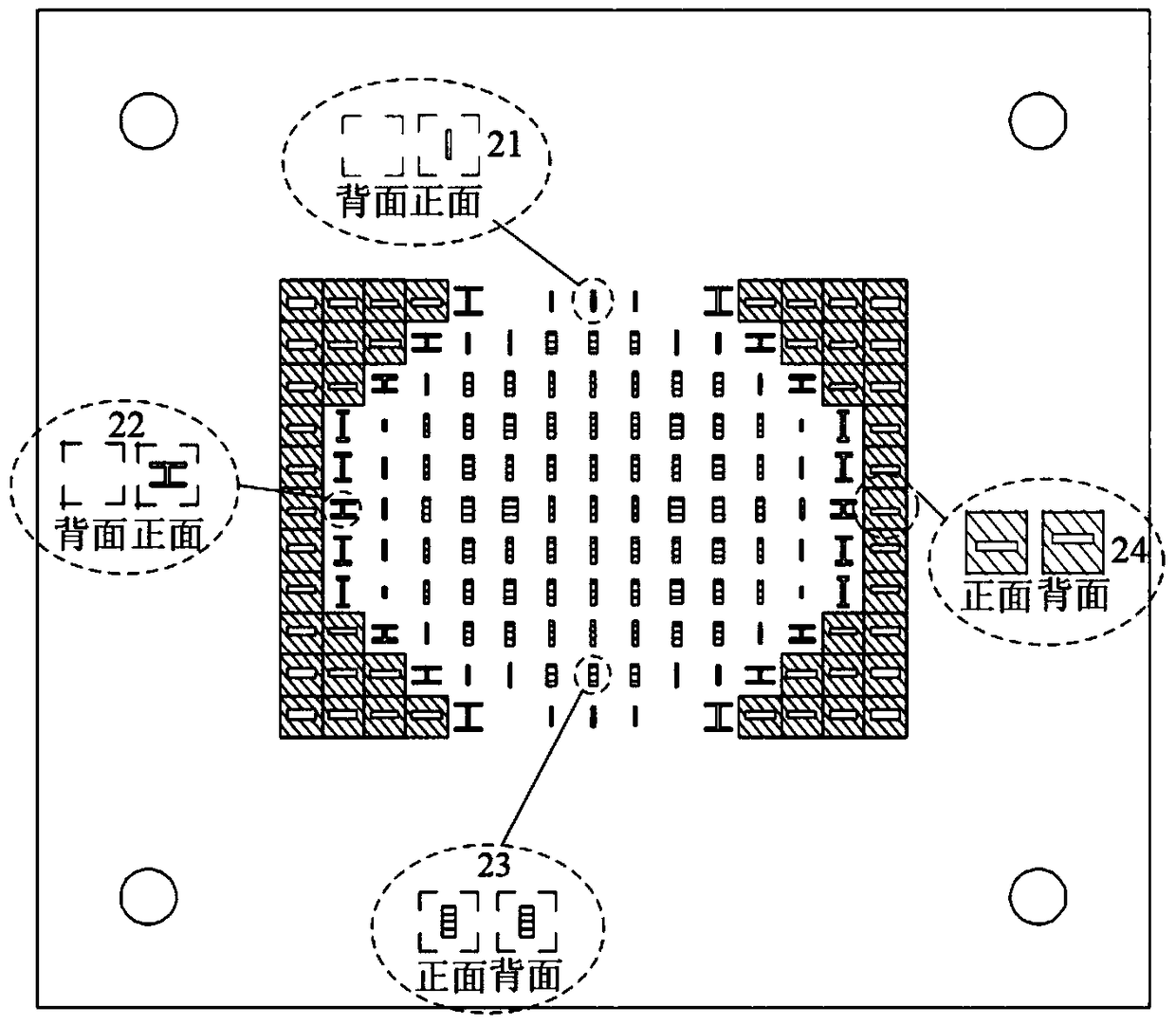

[0016] Such as figure 1 As shown in the schematic diagram of the overall structure of , a high-gain horn antenna based on metamaterial loading includes a standard horn antenna 1, a metamaterial plate 2, and four screws 3 for positioning and fixing the metamaterial plate. The metamaterial flat plate 2 consists of 22 first metamaterial structural units 21, 22 second metamaterial structural units 22, and 73 third metamaterial structural units printed on both sides of a low-loss Rogers5880 dielectric substrate 20 with a thickness of 0.127mm. The structural unit 23 and 46 fourth metamaterial structural units 24 are closely arranged in parallel, and four through holes 25 for positioning and fixing are drilled at the four corners of the metamaterial flat plate; the standard horn antenna 1 is selected to work at 75-110 GHz The W-band standard pyramid horn antenna is drilled with four screw holes 11 for positioning and fixing at the four corners of its output end face; The four throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com