A kind of production method of yogurt ice cream and the yogurt ice cream produced thereof

The technology of a yogurt ice cream and a production method, which is applied in the field of yogurt ice cream, can solve the problems of easy generation of ice slag, inability to effectively combine free water, etc., and achieve the effects of strong melting resistance, rich yogurt flavor and delicate taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

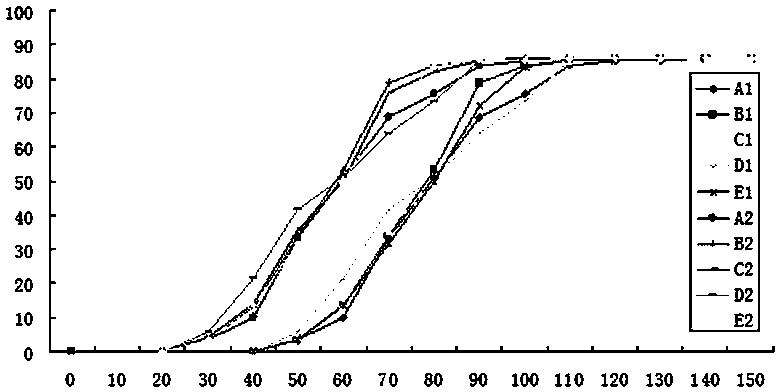

Image

Examples

no. 1 example

[0020] 1. Raw materials: raw milk 690kg, white sugar 110kg, skimmed milk powder 30kg, cream 100kg, maltose syrup 40kg, anhydrous butter 30kg, stabilizer 7kg, lactic acid bacteria 150U.

[0021] 2. Preparation method:

[0022] a) First heat the raw milk to 50°C, then add skim milk powder, white sugar, maltose syrup, anhydrous butter, stabilizer, and cream, stir while adding, and mix the raw materials to obtain a mixture liquid;

[0023] b) Homogenize the mixed material liquid, the homogeneous primary pressure is 150Bar, the secondary pressure is 70Bar, and the temperature is 75°C to obtain the homogeneous material liquid;

[0024] c) sterilizing the homogenized feed liquid to obtain a sterilized feed liquid, the sterilization temperature is 95° C., and kept for 300 seconds;

[0025] d) Cooling the sterilized feed liquid to 43°C, inoculating lactic acid bacteria into the sterilized feed liquid and stirring fully to disperse the lactic acid bacteria evenly, fermenting at 43°C, k...

no. 2 example

[0032] 1. Raw materials: 690kg of fresh milk, 150kg of white sugar, 50kg of skimmed milk powder, 80kg of cream, 20kg of malt syrup, 10kg of vegetable oil, 7kg of stabilizer, 200U of lactic acid bacteria.

[0033] 2. Preparation method:

[0034] a) First heat the raw milk to 50°C, then add skim milk powder, white sugar, maltose syrup, vegetable oil, stabilizer, stir while adding, and mix the raw materials to obtain a mixed material liquid;

[0035] b) Homogenize the mixed material liquid, the homogeneous primary pressure is 170Bar, the secondary pressure is 50Bar, and the temperature is 70°C to obtain the homogeneous material liquid;

[0036] c) sterilizing the homogenized feed liquid to obtain a sterilized feed liquid, and keeping the sterilization temperature at 95° C. for 300 seconds;

[0037] d) Cool down the sterilized feed liquid to 44°C, inoculate the lactic acid bacteria in the sterilized feed liquid and stir fully to disperse the lactic acid bacteria evenly, ferment a...

no. 3 example

[0044] 1. Raw materials: 690kg of fresh milk, 130kg of white sugar, 30kg of skimmed milk powder, 200kg of cream, 50kg of malt syrup, 7kg of stabilizer, 200U of lactic acid bacteria.

[0045] 2. Preparation method:

[0046] a) First heat the raw milk to 50°C, then add skim milk powder, white sugar, maltose syrup, cream and stabilizer, stir while adding, and mix the raw materials to obtain a mixed material liquid;

[0047] b) Homogenize the mixed material liquid, the homogeneous primary pressure is 180Bar, the secondary pressure is 40Bar, and the temperature is 65°C to obtain the homogeneous material liquid

[0048] c) sterilizing the homogenized feed liquid to obtain a sterilized feed liquid, and keeping the sterilization temperature at 95° C. for 300 seconds;

[0049] d) Cool down the sterilized feed liquid to 45°C, inoculate the lactic acid bacteria in the sterilized feed liquid and stir fully to disperse the lactic acid bacteria evenly, ferment at 45°C, heat-preserve and fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com