Broaching machine feeding plate

A technology of feeding plate and sliding plate, which is applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of poor product structure uniformity, low pass rate, and workpiece surface damage, so as to achieve good product structure uniformity, improve production efficiency, and improve consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

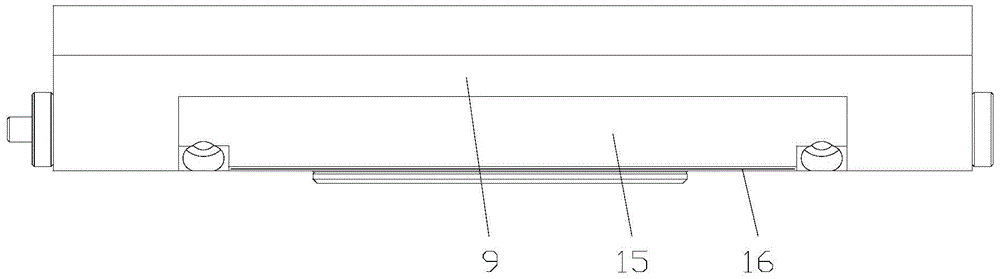

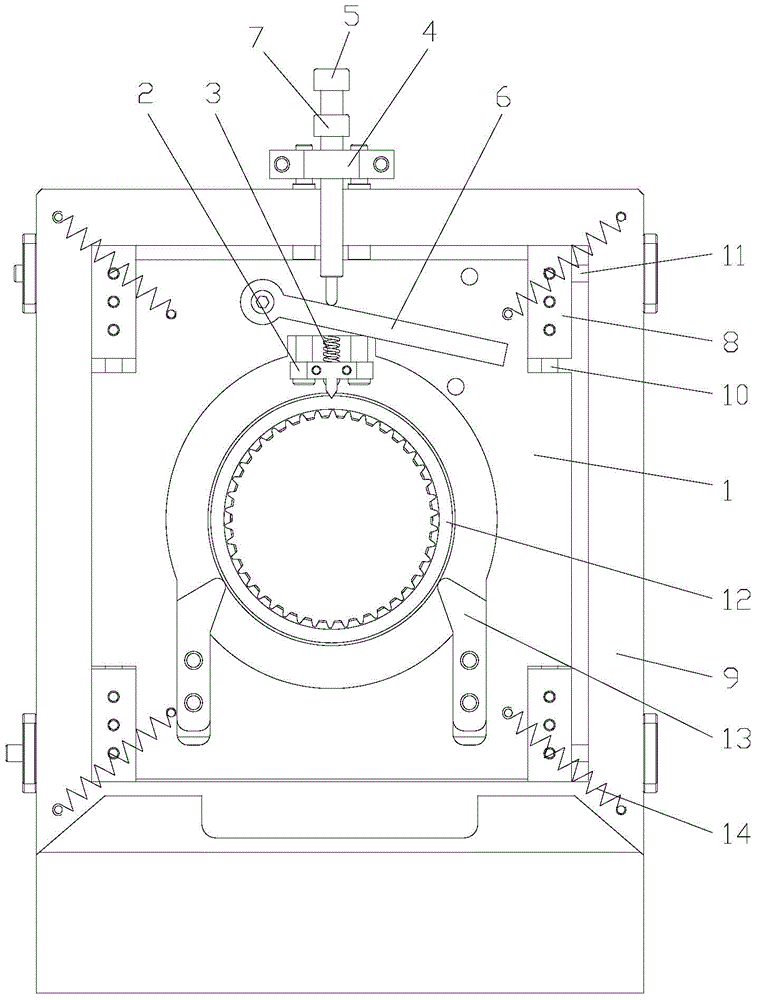

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 As shown in the figure: the feeding plate of the broaching machine in this embodiment includes a base 9, a transition piece 8, a first positioning rod 10, a second positioning rod 11, a slide plate 1, a clamping positioning mechanism and a Chip removal block 15; the slide plate 1 is slidably connected to the transition piece 8 through the first positioning rod 10 along the lengthwise direction of the first positioning rod 10, and the transition piece 8 is connected to the transition piece 8 through the second positioning rod 11 along the second positioning rod 11. The longitudinal single degree of freedom is slidably connected to the base 9, and the first positioning rod 10 and the second positioning rod 11 are perpendicular to each other; the slide plate 1 is provided with a vertically penetrating cavity for accommodating the workpiece 12; the clamping positioning The mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com