Scrapped light weapon destroying equipment

A technology for light weapons and equipment, applied in the field of scrapped light weapons destruction equipment, can solve problems such as large working space, adverse environmental impact, and reduced work efficiency, so as to reduce water consumption, improve destruction efficiency and effect, and reduce destruction pressure requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

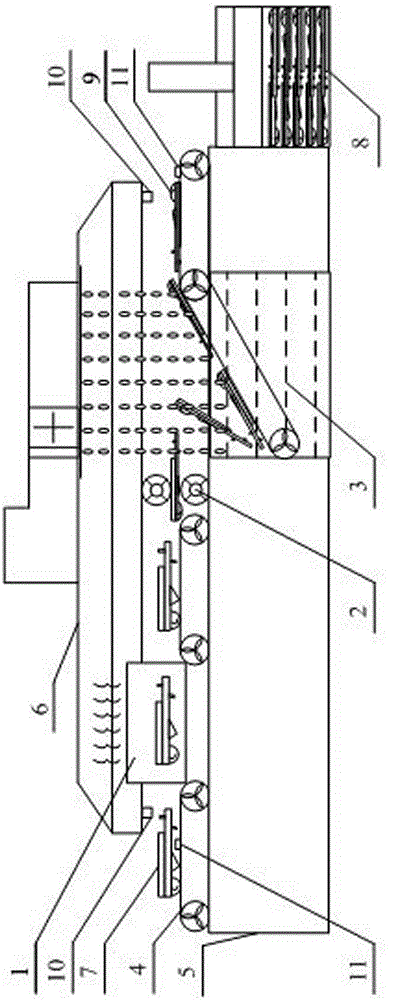

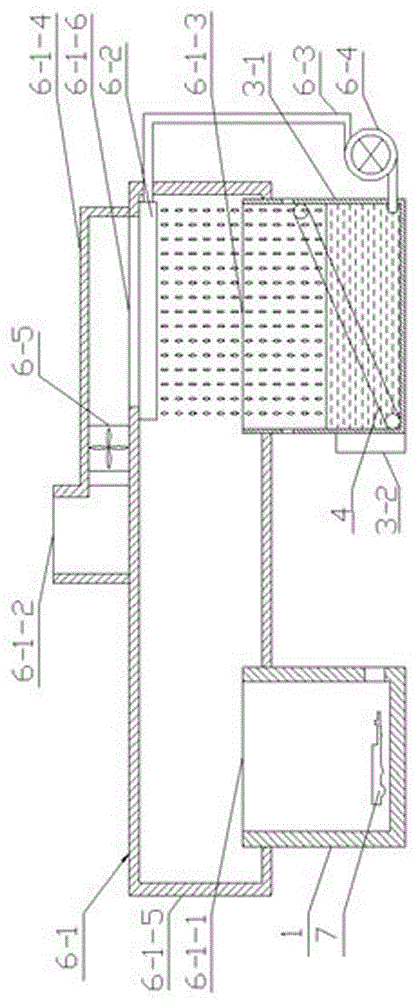

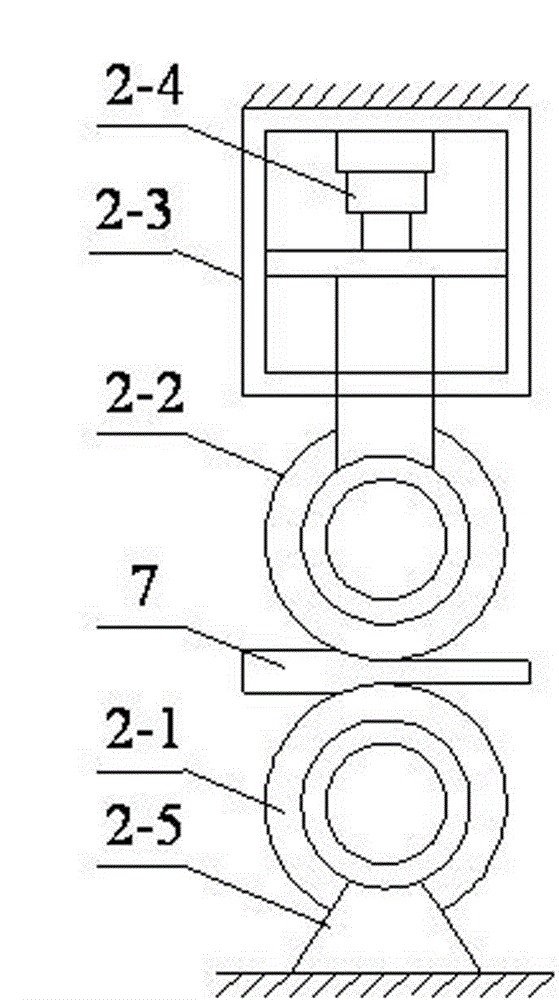

[0018] refer to figure 1 , The embodiment includes a workbench 5, a heating unit 1, a rolling unit 2, a cooling unit 3, a feeding unit 4, a dust removal unit 6, a control unit and a metal baler 8 which are sequentially arranged on the workbench. Wherein, the heating unit 1 , the rolling unit 2 and the cooling unit 3 are sequentially arranged on the workbench 5 . The feeding unit 4 is arranged between the heating unit 1 , the rolling unit 2 and the cooling unit 3 , and is used for transporting the firearms 7 to be destroyed and the firearms 9 to be destroyed. The dust removal unit 6 is arranged on the upper part of the heating unit 1 and communicated with the heating unit 1 to filter and purify the smoke generated by the heating unit 1 . In this example, the heating unit 1 is composed of an induction heating furnace and an intermediate frequency power supply. The intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com