Method for treating surface of fluorphosphate glass

A fluorophosphate glass and surface treatment technology, applied in the field of laser glass, can solve the problems of increased roughness, unsatisfactory effect, surface impurities and crack layers are not eliminated, achieve high-power laser output, improve glass surface Topography, removal of scratches and the effect of microcracked layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

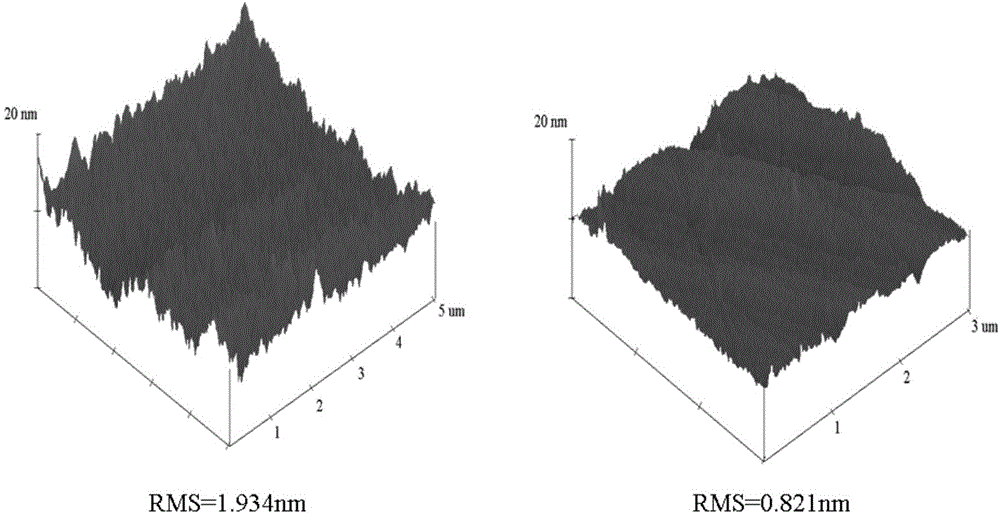

Image

Examples

Embodiment 1

[0027] The present embodiment fluorophosphate glass surface treatment method, this method comprises the following steps:

[0028] 1) configure the described mixed acid and mixed alkali solution in the following proportions;

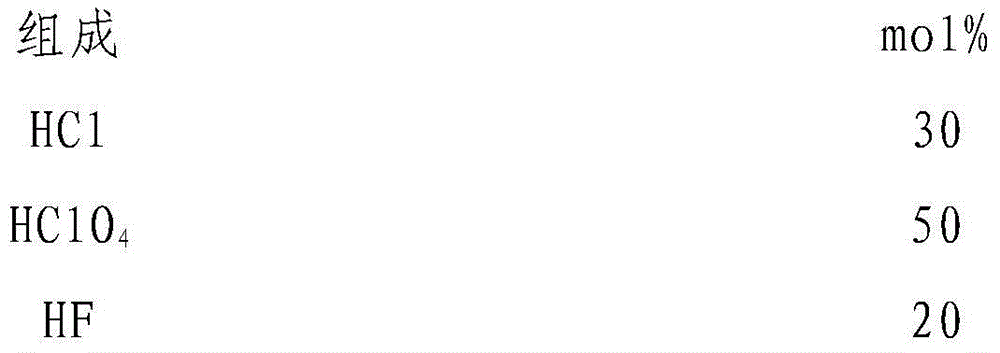

[0029] The mixed acid is composed of hydrochloric acid, perchloric acid and hydrofluoric acid, and its composition is as follows:

[0030]

[0031] The mixed alkali solution is composed of potassium hydroxide and sodium hydroxide in the following proportions:

[0032] Composition mol%

[0033] KOH60

[0034] NaOH 40

[0035] 2) Put the polished fluorophosphorus glass into a polytetrafluoroethylene box, add deionized water, then put it into an ultrasonic cleaner, wash it at 30°C for 5 minutes, and take out the fluorophosphorus glass;

[0036] 3) The mixed acid configured to be diluted is composed of the described mixed acid and pure water in a molar percentage of 1:1;

[0037] 4) Put the fluorophosphorus glass ultrasonically cleaned with deionized ...

Embodiment 2

[0042] The method for treating the surface of fluorophosphate glass in this embodiment comprises the following steps:

[0043] 1) configure the described mixed acid and mixed alkali solution in the following proportions;

[0044] The mixed acid is composed of hydrochloric acid, perchloric acid and hydrofluoric acid, and its composition is as follows:

[0045]

[0046] The mixed lye is composed of potassium hydroxide and sodium hydroxide in the following proportions:

[0047] Composition mol%

[0048] KOH60

[0049] NaOH 40

[0050] 2) Put the polished fluorophosphorus glass into a polytetrafluoroethylene box, add deionized water, then put it into an ultrasonic cleaner, wash it at 30°C for 5 minutes, and take out the fluorophosphorus glass;

[0051] 3) The mixed acid configured to be diluted is composed of the described mixed acid and pure water in a molar percentage of 1:1;

[0052] 4) Put the fluorophosphorus glass ultrasonically cleaned with deionized water into a po...

Embodiment 3

[0057] The method for treating the surface of fluorophosphate glass in this embodiment comprises the following steps:

[0058] 1) configure the described mixed acid and mixed alkali solution in the following proportions;

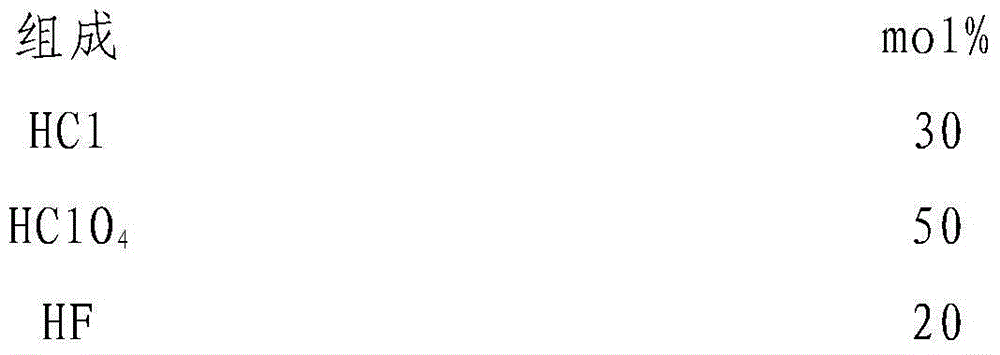

[0059] The mixed acid is composed of hydrochloric acid, perchloric acid and hydrofluoric acid, and its composition is as follows:

[0060]

[0061] The mixed alkali solution is composed of potassium hydroxide and sodium hydroxide in the following proportions:

[0062] Composition mol%

[0063] KOH60

[0064] NaOH 40

[0065] 2) Put the polished fluorophosphorus glass into a polytetrafluoroethylene box, add deionized water, then put it into an ultrasonic cleaner, wash it at 30°C for 5 minutes, and take out the fluorophosphorus glass;

[0066] 3) The mixed acid configured to be diluted is composed of the mixed acid and pure water in a molar percentage of 1:6;

[0067]4) Put the fluorophosphorus glass ultrasonically cleaned with deionized water into a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com