Multifunctional fluid engine

An engine and multi-functional technology, applied in the fields of wind energy, airflow as kinetic energy, water energy and steam flow, it can solve problems such as difficulty in improving efficiency, and achieve the effect of simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] method one"

[0014] One-stage drive multifunctional fluid engine 【1】

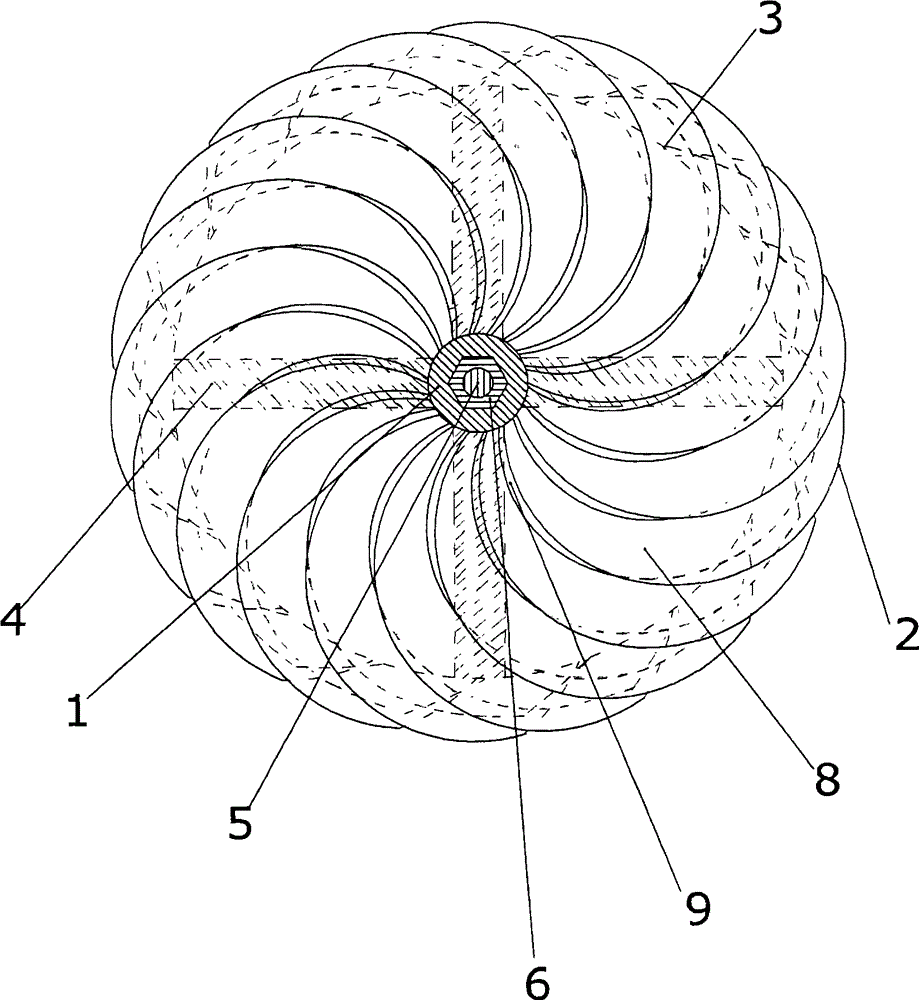

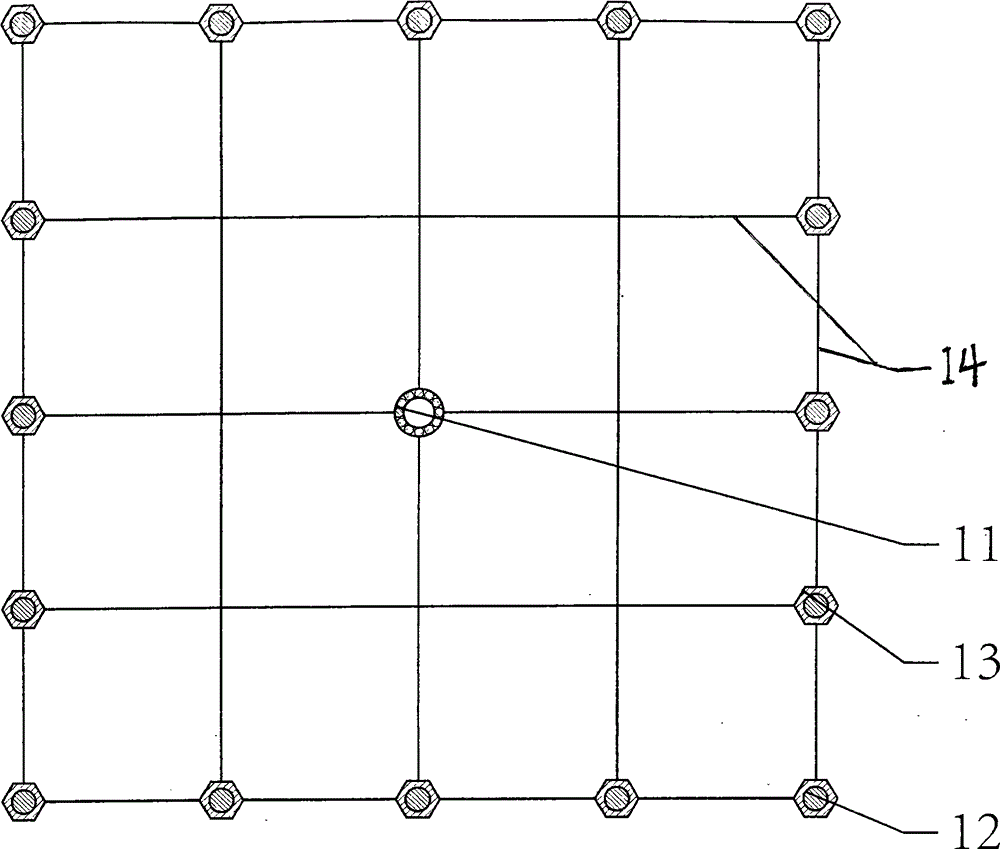

[0015] The utility model relates to a multifunctional generating machine for using fluid as kinetic energy, and is especially suitable for generating machines for steam flow, water energy, wind energy, and air flow as kinetic energy. It includes: bushing (1), concentrating drive vane (2), inlet neck (3), supporting drive vane (4), shaft (5), nut (6), flange frame (7), bearing (11 ).

[0016] A bearing (11) is respectively arranged in the middle of the two ends of the hurdle frame (7), and a movable shaft (5) is arranged in the bearing (11). The tail-stage bushing (1) is fixed with a tail-stage nut (6); between the tail-stage bushing (1) and the outlet of the inlet neck (3) there are multiple flow-concentrating drive vanes (2) The tilting head of the flow driving blade (2) is designed at the outlet of the inlet neck (3), and there is a gap between the blades, which is a fluid flow channel. Its fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com