Ball screw releasing-engaging transmission and resetting device

A technology of reset device and clutch transmission, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. It can solve the problems of no clutch and reset, low transmission efficiency, and many processing procedures, so as to save time and maintain Convenience and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

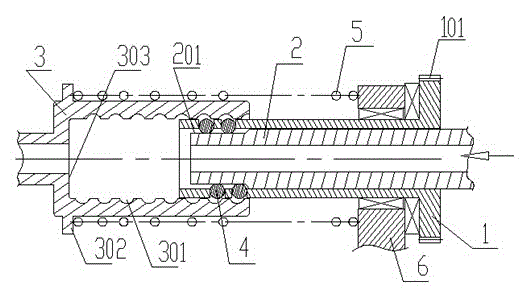

[0031] The screw rod 2 is a smooth screw rod; a threaded raceway 301 is processed in the inner hole of the nut jacket 3, and a step II303 is formed at the front end of the inner hole; 6 connected; the screw 2 and the cage 1 are connected through the steel ball 4 and the threaded raceway 301, and the clutch transmission device and reset device form a clutch transmission reset device.

[0032] Further as a priority program, such as Figure 6 As shown, the end of the inner hole of the nut cover 3 is processed with a step III304, and the nut cover 3 is also provided with a reset step 302. One end of the return spring 5 is fixed to the reset step 302, and the other end is fixed to the cage fixing seat. 6 fixed.

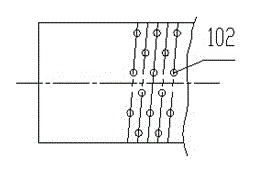

[0033] Further, the distance between the centers of the corresponding through holes 102 after the cage 1 is deployed is an integer multiple of the screw pitch.

[0034] Further, the thread raceway can be a single-start or multi-start thread, and the multi-start thread ra...

Embodiment 2

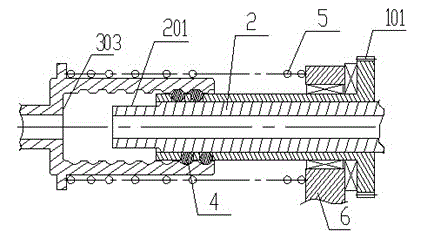

[0038] Such as Figure 7 As shown, the screw rod 2 is a screw rod processed with a threaded raceway, and the two ends of the screw rod 2 are processed with steps I201; the inner hole of the nut jacket 3 is processed into a smooth hole, and the end of the inner hole of the nut jacket 3 is processed with steps III304, the nut jacket 3 is provided with a reset step 302; the end of the cage fixing seat 6 is provided with a step IV 601, and the part of the step IV 601 is provided with a slot 602; the right end of the nut jacket 3 is arranged in the step IV 601, and the reset step 302 Set in the slot hole 602, when the gear 101 of the cage 1 is driven to rotate by an external force, and the reset step 302 is pushed to the left end by the force in the direction of the steel ball 4, at this time the screw rod 2 will move in a straight line and be pulled to the holding position. The gear 101 direction of the frame 1, when the spring fixing seat 7 contacts the left end surface of the nu...

Embodiment 3

[0042] As an equivalent alternative to Example 2, such as Figure 8 As shown, the screw rod 2 is a screw rod processed with a threaded raceway, and the two ends of the screw rod 2 are processed with steps I201; the inner hole of the nut jacket 3 is processed into a smooth hole, and the end of the inner hole of the nut jacket 3 is processed with steps III304; the step I201 at the left end of the screw mandrel 2 is fixed with a spring holder 7; the reset device is formed by connecting the spring holder 7 and the nut jacket 3 by a return spring; the clutch transmission device and the reset device form a clutch Transmission reset device.

[0043] Further, the distance between the centers of the corresponding through holes 102 after the cage 1 is deployed is an integer multiple of the screw pitch.

[0044] Further, the thread raceway can be a single-start or multi-start thread, and the multi-start thread raceway can use large-diameter steel balls 4 when the load is large, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com