High-pressure waste energy recovery hydraulic turbine test stand and control method thereof

A hydraulic turbine and residual energy recovery technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of poor adjustability, no automatic control, and inconvenient recording of hydraulic permeability. Problems such as the characteristic parameters outside the flat surface, to achieve the effect of increasing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

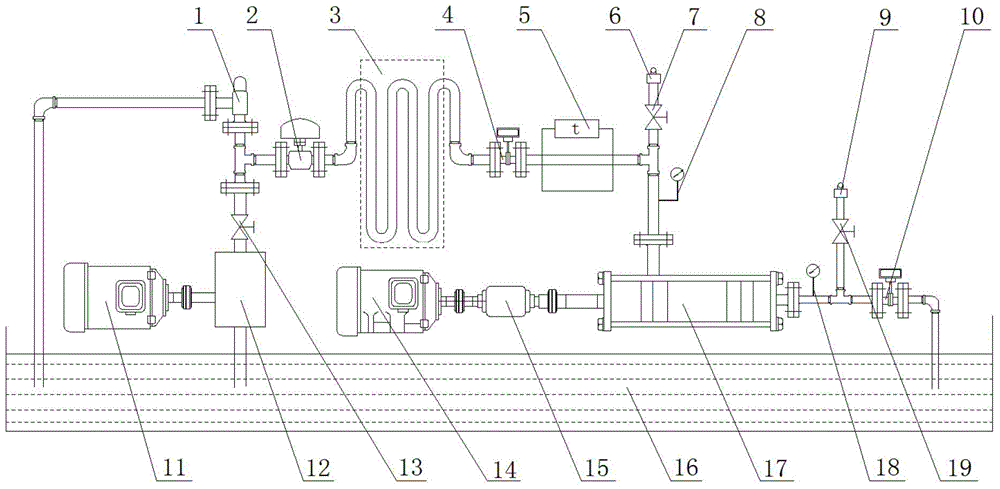

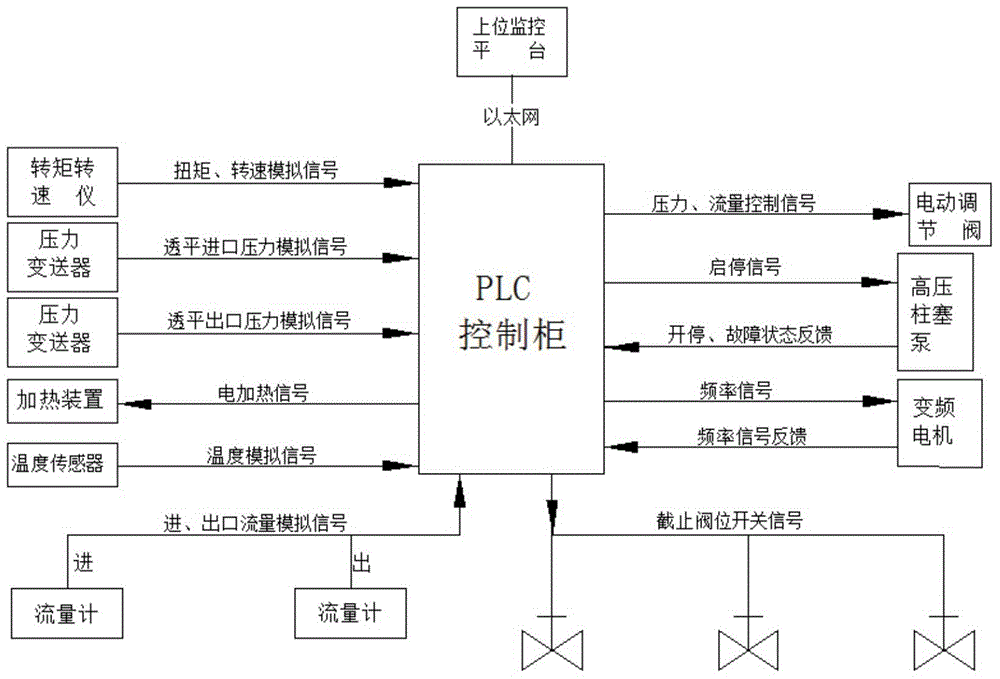

[0027] figure 1 It is a scheme diagram of the high-pressure residual energy recovery hydraulic turbine test bench system of the present invention. Including hydraulic turbine 17, generator 14, variable frequency motor 11, high pressure plunger pump 12, overflow valve 1, electric control valve 2, heating device 3, turbine flowmeter 4, 10, temperature sensor 5, pressure transmitter 6,9, pressure gauge 8,18, pool 16, torque tachometer 15.

[0028] The connection method is: one end of the torque tachometer 15 is connected to the shaft of the hydraulic turbine 17 through a coupling, the other side is connected to the generator 14 through a coupling, and the shaft end of the high-pressure plunger pump 12 is connected to the variable frequency motor 11 connected by a coupling....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com