Gain self-adjustment type supercoiling slip form control method for electro-hydraulic positioning servo system

A technology of electro-hydraulic position servo and control method, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of controller chattering, tracking error, discontinuity of sliding mode controller, etc. Conservative, the effect of improving system servo accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

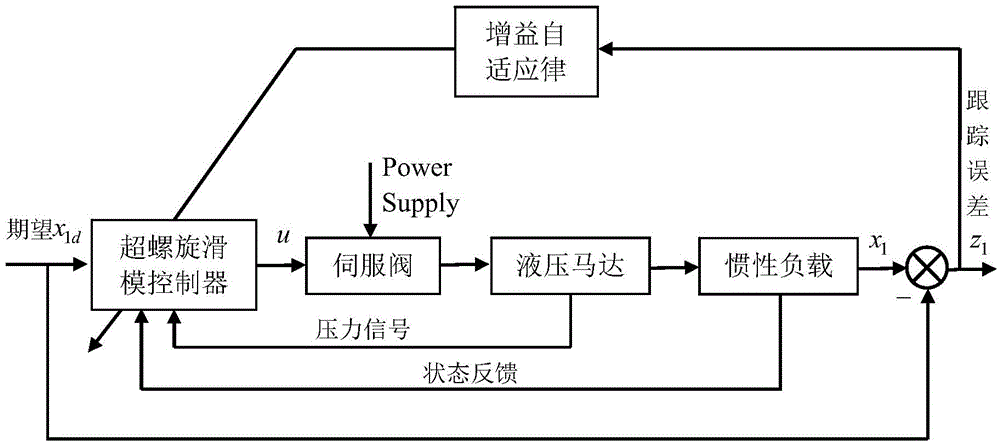

[0018] combine Figure 1~2 The gain self-adjusting superhelical sliding mode control method of the electro-hydraulic position servo system of the present invention comprises the following steps:

[0019] Step 1, establishing the mathematical model of the hydraulic electrohydraulic position servo system;

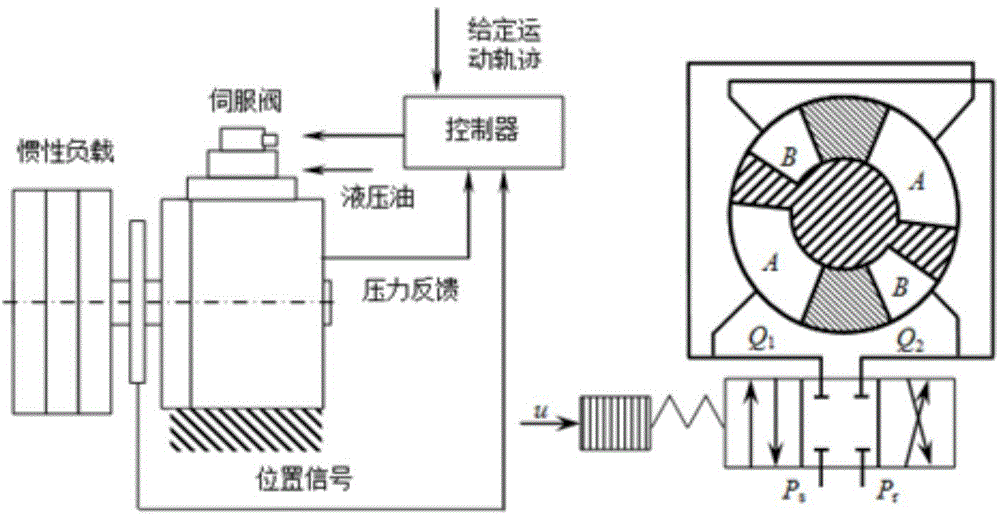

[0020] (1.1) The hydraulic electrohydraulic position servo system considered in the present invention is as follows: figure 1 Shown is an inertial load driven by a hydraulic motor controlled by a servo valve.

[0021] figure 1 On the left is the structure of the electro-hydraulic position servo system, and on the right is the schematic diagram of the structure of the hydraulic motor.

[0022] Therefore, according to Newton's second law, the equation of motion for an inertial load is:

[0023] J ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com