Flat connection CPU cooling and dust removal device

A dust removal device and flat connection technology, which is applied in electrostatic cleaning, instruments, and electrical digital data processing, etc., can solve the problems of reduced cooling effect, increased thermal resistance of heat dissipation, and increased load, so as to improve reliability and stability performance, enhanced CPU heat dissipation, and low airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

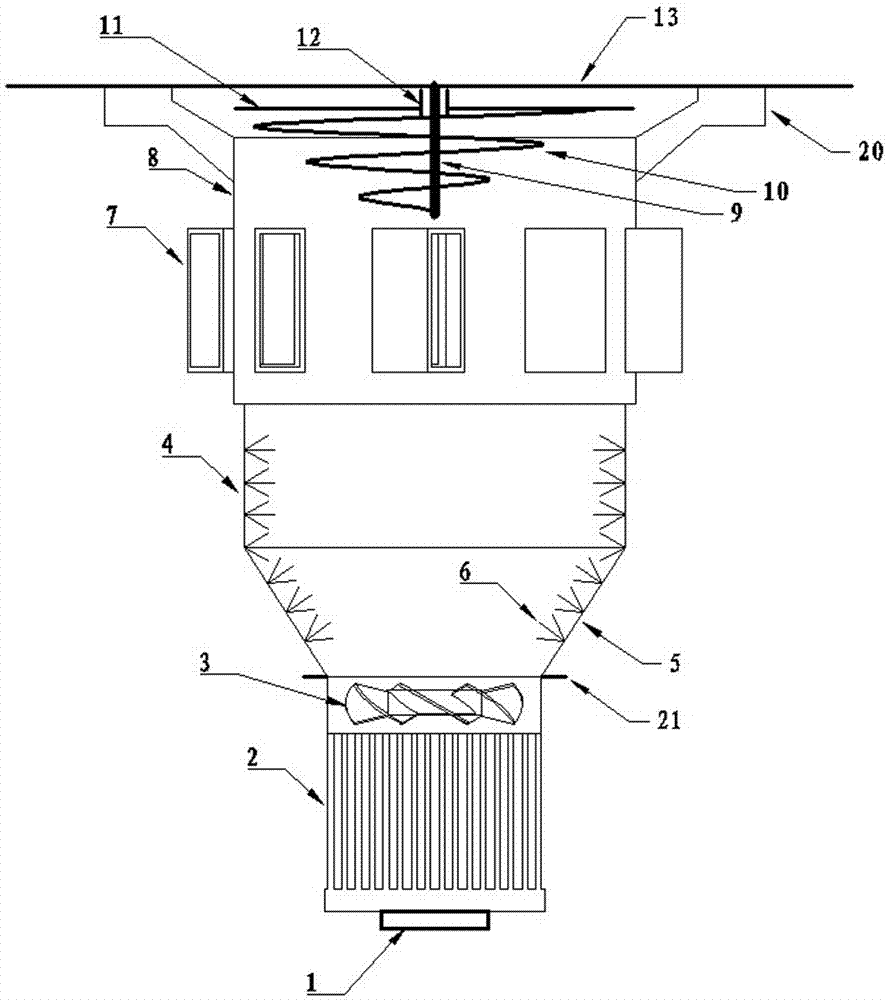

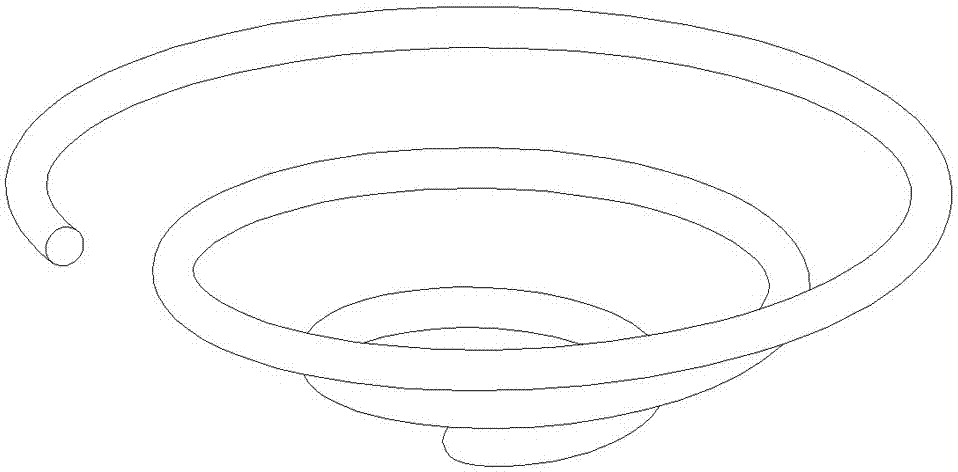

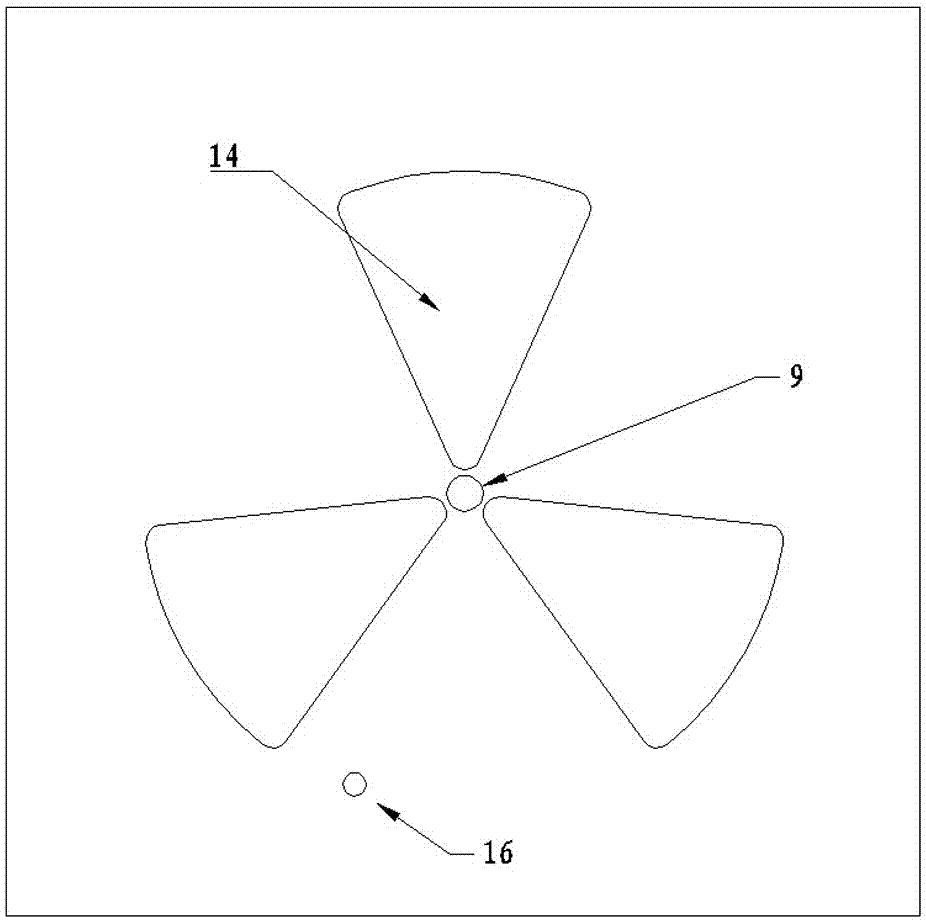

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The flat-connected CPU heat dissipation and dust removal device shown includes CPU1 and radiator 2, radiator 2 is fixed on CPU1, fan 3 is fixed on radiator 2, and fan 3 is integrated with cone tube 5, cylinder tube 4 and cyclone 8. When the chassis plate 13 is installed, the parts will realize the flat joint surface matching 21 to achieve air guidance and basic airtightness; the cyclone 8 is fixed on the chassis plate 13 through the support feet 20, and the cyclone 8 has several tangential air inlets 7 in the chassis There are electrostatic fibers 6 with appropriate density and length in the cone tube 5 and the cylinder tube 4; the shaft 9 is fixed on the chassis plate 13, and the front end of the shaft 9 is connected with the small end of the tower spring 10; the valve disc 11 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com