Equipment used for stalactite formation and stalactite formation method

A technology of stalactites and equipment, which is applied in the field of stalactite forming equipment and stalactite forming, can solve the problems of time consumption, manpower and material resources, stalactites lose their natural beauty, and high manufacturing costs, so as to reduce forming time, facilitate decomposition, and facilitate freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is further described:

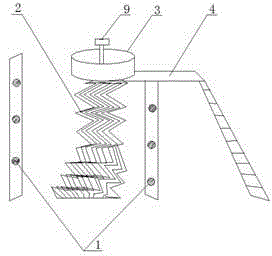

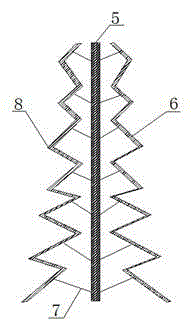

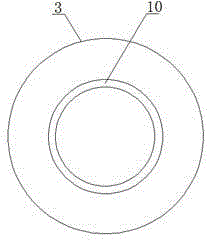

[0027] like figure 1 and figure 2 Shown: the stone molding equipment, including the hot air blower 1, the skeleton 2 and the batching tower 3 installed above the skeleton 2, the batching tower 3 is fixed above the skeleton 2 through the fixing frame 4 and maintains a certain distance from the skeleton 2 to ensure the solution The slurry is in good contact with the skeleton 2, which is conducive to the flow of the slurry. The skeleton 2 is composed of a middle support column 5 and a number of shape frames 6 on the periphery. The support column 5 and the shape frame 6 are fixedly connected through the bracket 7. The shape of the skeleton 2 By changing the shape of the support column 5 and the shape frame 6, the shape of the frame 2 can be designed into a spiral shape, a flower shape, a cone shape, etc. according to actual needs, eliminating the need for cutting the stalactites....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com