Method for preparing direct reduction iron and gelation materials through low-grade iron ore

A technology for lean iron ore and reduced iron, which is applied in the field of preparing direct reduced iron and cementitious materials by using lean iron ore, and can solve the problem of inability to prepare cementitious materials and iron, low yield of direct reduced iron, and poor iron ore. problems such as low iron content, to achieve the effect of improving the utilization effect and the added value of the product, shortening the preparation cycle and process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

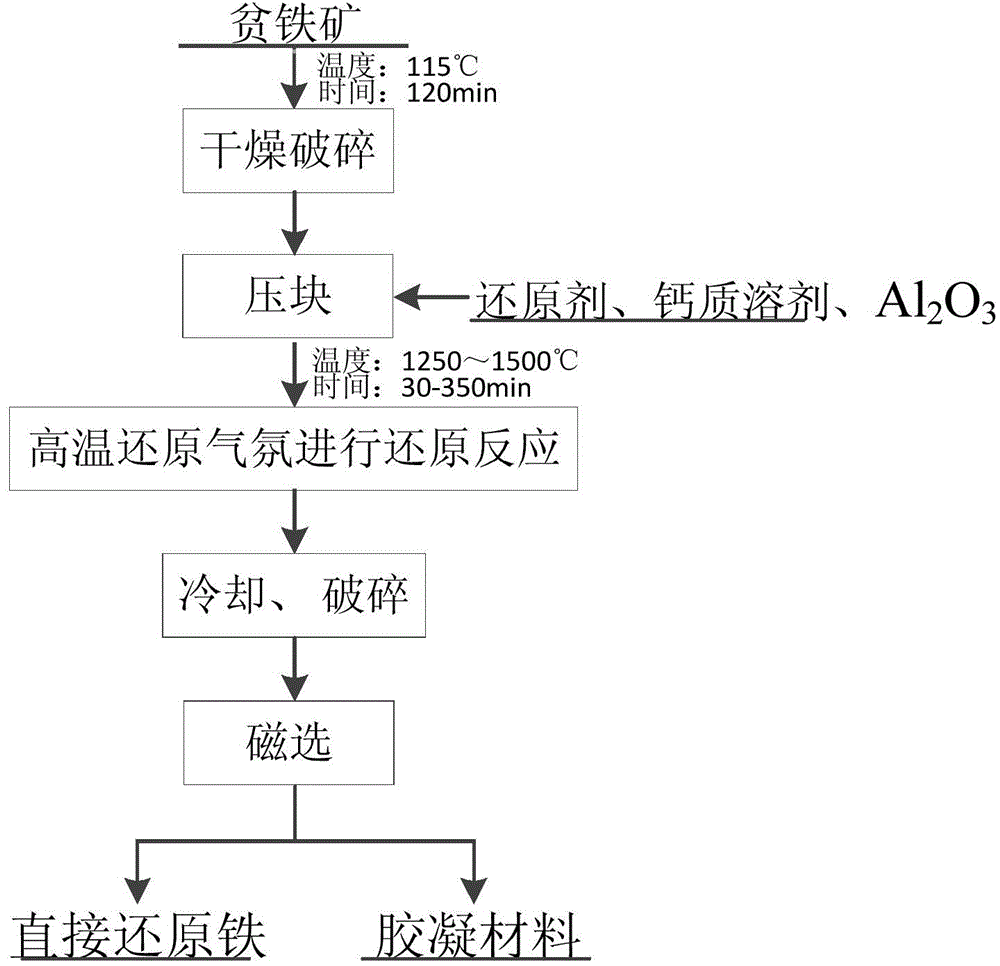

[0023] The method of utilizing lean iron ore of the present invention to prepare direct reduced iron and cementitious material comprises the following steps:

[0024] 1) Take lean iron ore, Al 2 o 3 , lignite, and limestone, a mixture of lime and calcium carbonate in any proportion, dry, crush and grind the lean iron ore and add Al 2 o 3 , lignite, and limestone, lime and calcium carbonate mixture in any proportion to obtain the furnace raw materials, and then place the furnace raw materials into the furnace after briquetting, and carry out reduction and roasting reactions under a reducing atmosphere;

[0025] 2) The product of the reduction and roasting reaction is taken out of the furnace, and then cooled, crushed and magnetically separated to obtain directly reduced iron and gelling materials.

[0026] In step 1), dry, crush and grind the poor iron until the particle size is less than 300 mesh, and then add Al 2 o 3 , lignite, and limestone, a mixture of lime and calci...

Embodiment 2

[0032] The method of utilizing lean iron ore of the present invention to prepare direct reduced iron and cementitious material comprises the following steps:

[0033] 1) Take Al 2 o 3 , lean iron ore, coking coal, and a mixture of limestone, lime, calcium carbonate, fluorite and calcium sulfate in any proportion, dry, crush and grind the lean iron ore and add Al 2 o 3 , coking coal and limestone, lime, calcium carbonate, fluorite and calcium sulfate in any proportion of the mixture to obtain the raw materials into the furnace, and then the raw materials into the furnace are compacted and placed in the furnace, and the reduction and roasting reactions are carried out in a reducing atmosphere ;

[0034] 2) The product of the reduction and roasting reaction is taken out of the furnace, and then cooled, crushed and magnetically separated to obtain directly reduced iron and gelling materials.

[0035] In step 1), dry, crush and grind the poor iron until the particle size is les...

Embodiment 3

[0041] The method of utilizing lean iron ore of the present invention to prepare direct reduced iron and cementitious material comprises the following steps:

[0042] 1) Take lean iron ore, Al 2 o 3 , anthracite, and a mixture of limestone, lime, calcium carbonate and fluorite in any proportion, dry, crush and grind the lean iron ore and add Al 2 o 3 , anthracite, limestone, lime, calcium carbonate and fluorite in any proportion of the mixture to obtain the furnace raw materials, and then put the furnace raw materials into the furnace after briquetting, and carry out reduction and roasting reactions in a reducing atmosphere;

[0043] 2) The product of the reduction and roasting reaction is taken out of the furnace, and then cooled, crushed and magnetically separated to obtain directly reduced iron and gelling materials.

[0044] In step 1), dry, crush and grind the poor iron until the particle size is less than 300 mesh, and then add Al 2 o 3, anthracite, and a mixture of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com