A method and device for controlling ferroelectric crystal domains

A ferroelectric crystal and electric domain technology, which is applied in the field of preparation of ferroelectric materials, can solve the problems of inability to accurately control the morphology and size of electric domains, reduce piezoelectric constants, limit high-voltage electric effects, etc., and achieve good piezoelectricity. Effects of thermal stability, enhanced piezoelectric effect, and improved polarization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

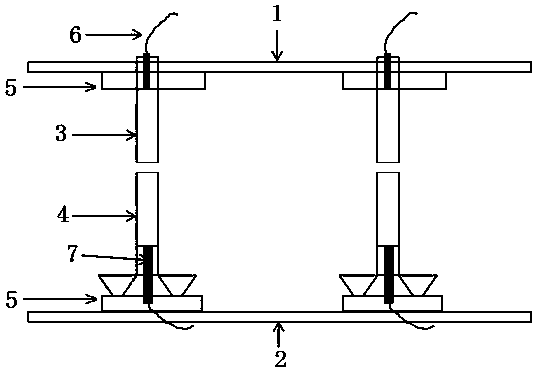

Image

Examples

Embodiment 1

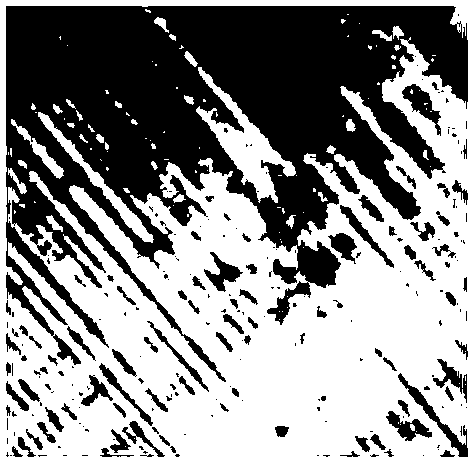

[0042] Embodiment 1: multi-domain PMN-PT crystal

[0043] Crystal sample size: 3mmх3mmх15mm, phase structure at room temperature: tetragonal phase, crystal orientation: [111], electric domain observation direction: [111].

[0044] Polarization process:

[0045] Step 1. Use the fixture module to fix the PMN-PT crystal sample, then place the fixture in a temperature-controlled furnace, raise the temperature to 210 degrees, the temperature control accuracy is 0.1 degrees, and the holding time is 10 minutes;

[0046] Step 2. Apply an electric field with a voltage intensity of 12 V / mm and a current of 1 mA along the direction perpendicular to the electrodes, and keep it for 10 minutes;

[0047] Step 3. Lower the temperature at a rate of 0.5 degrees per minute, and increase the voltage intensity at the same time so that it is always above twice the coercive field. The current value is kept at 1 mA; when the temperature drops to 100 degrees, keep it warm for 5 minutes. It is 300 vo...

Embodiment 2

[0049] Embodiment 2: Monodomain PMN-PT crystal

[0050] Crystal sample size: 3mmх3mmх15mm, phase structure at room temperature: tetragonal phase, crystal orientation: [001] and [100], electric domain observation direction: [001].

[0051] Polarization process:

[0052] Step 1. Use the fixture module to fix the PMN-PT crystal sample, then place the fixture in a temperature-controlled furnace, heat up to 200 degrees, the temperature control accuracy is 0.1 degrees, and the holding time is 20 minutes;

[0053] Step 2. Apply an electric field with a voltage intensity of 12 V / mm and a current of 1 mA along the direction perpendicular to the electrodes, and keep it for 10 minutes;

[0054] Step 3. Lower the temperature at a rate of 1.0 degrees per minute, and at the same time increase the voltage intensity so that it is always above twice the coercive field and keep the current value at 1 mA; when the temperature drops to 150 degrees, keep it warm for 5 minutes. 50 volts / mm; when ...

Embodiment 3

[0056] Embodiment 3: Multi-domain PIN-PMN-PT crystal

[0057] Crystal sample size: 3mmх3mmх15mm, phase structure at room temperature: tetragonal phase, crystal orientation: [111], electric domain observation direction: [111].

[0058] Polarization process:

[0059] Step 1. Use the fixture module to fix the PIN-PMN-PT crystal sample, then place the fixture in a temperature-controlled furnace, raise the temperature to 300 degrees, the temperature control accuracy is 0.1 degrees, and the holding time is 20 minutes;

[0060] Step 2. Apply an electric field with a voltage intensity of 15 V / mm and a current of 1 mA along the direction perpendicular to the electrodes, and keep it for 20 minutes;

[0061] Step 3. Lower the temperature at a rate of 1.0 degrees per minute, and at the same time increase the voltage intensity so that it is always above twice the coercive field and keep the current value at 1 mA; when the temperature drops to 200 degrees, keep it warm for 5 minutes. 90 v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com