Corner protection part used for wall

A technology of corner protection and aluminum alloy, which is applied in the direction of roads, roads, building structures, etc., can solve the problems of low safety, deformation of guardrails, and high production cost of corner protection, so as to reduce product quality, better absorb impact energy, and improve durability. The effect of erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

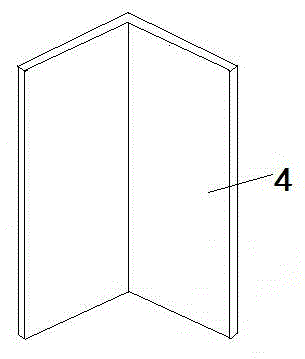

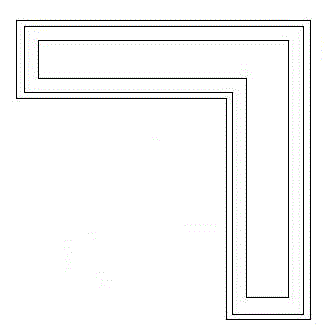

[0043] A corner protector for walls, the section of the corner protector is "L" shaped, the core of the corner protector is made of particle-reinforced foamed aluminum-based composite material, the periphery of the core is wrapped with an elastic material layer, the outer layer of the elastic material is an aluminum alloy shell, and the aluminum alloy shell The surface of the body is coated with an organic paint, which is characterized in that:

[0044] The elemental composition of the aluminum alloy shell is as follows: chemical composition (weight percent): Cu: 2%, Mg: 1%, Sn: 1%, Cr: 0.8%, W: 0.7%, Co: 0.5%, Bi: 0.3% , Nb: 0.2%, Mo: 0.08%, Ba: 0.06%, Sb: 0.02%, and the balance is Al and unavoidable impurities;

[0045] The preparation method of the aluminum alloy shell includes the following steps: according to the composition of the above-mentioned aluminum alloy shell elements, the pure aluminum is first added to the melting furnace, and the furnace temperature is control...

Embodiment 2

[0056] A corner protector for walls, the section of the corner protector is "L" shaped, the core of the corner protector is made of particle-reinforced foamed aluminum-based composite material, the periphery of the core is wrapped with an elastic material layer, the outer layer of the elastic material is an aluminum alloy shell, and the aluminum alloy shell The surface of the body is coated with an organic paint, which is characterized in that:

[0057] The elemental composition of the aluminum alloy shell is as follows: chemical composition (weight percent): Cu: 3%, Mg: 2%, Sn: 2%, Cr: 0.9%, W: 0.8%, Co: 0.6%, Bi: 0.4% , Nb: 0.3%, Mo: 0.09%, Ba: 0.07%, Sb: 0.03%, and the balance is Al and unavoidable impurities;

[0058] The preparation method of the aluminum alloy shell includes the following steps: according to the composition of the above-mentioned aluminum alloy shell elements, the pure aluminum is first added to the melting furnace, and the furnace temperature is control...

Embodiment 3

[0069] A corner protector for walls, the section of the corner protector is "L" shaped, the core of the corner protector is made of particle-reinforced foamed aluminum-based composite material, the periphery of the core is wrapped with an elastic material layer, the outer layer of the elastic material is an aluminum alloy shell, and the aluminum alloy shell The surface of the body is coated with an organic paint, which is characterized in that:

[0070] The elemental composition of the aluminum alloy shell is: chemical composition (weight percent): Cu: 2.5%, Mg: 1.5%, Sn: 1.5%, Cr: 0.85%, W: 0.75%, Co: 0.55%, Bi: 0.35% , Nb: 0.25%, Mo: 0.085%, Ba: 0.065%, Sb: 0.025%, and the balance is Al and unavoidable impurities;

[0071]The preparation method of the aluminum alloy shell includes the following steps: according to the composition of the above-mentioned aluminum alloy shell elements, the pure aluminum is first added to the melting furnace, and the furnace temperature is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com