Method for shaping table surface of semiconductor chip

A semiconductor and chip technology, applied in the field of semiconductor chip production, can solve the problems of poor coordination, rough cutting surface, scrapped devices, etc., and achieve the effects of fine angle matching, improved efficiency, and avoiding edge collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

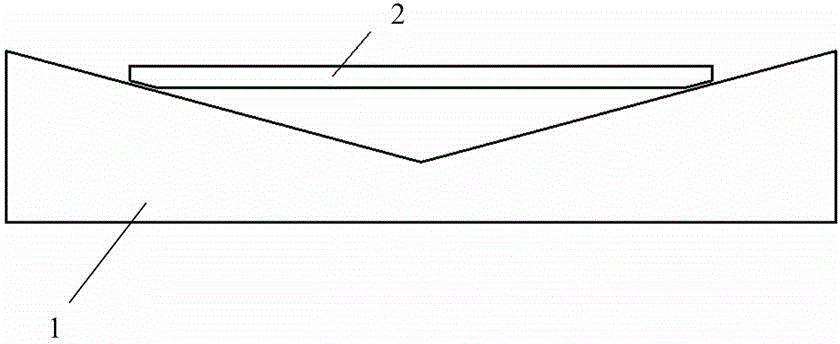

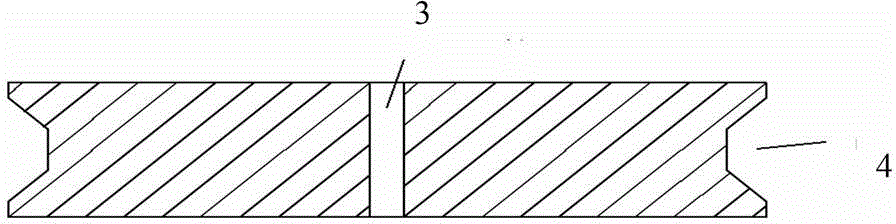

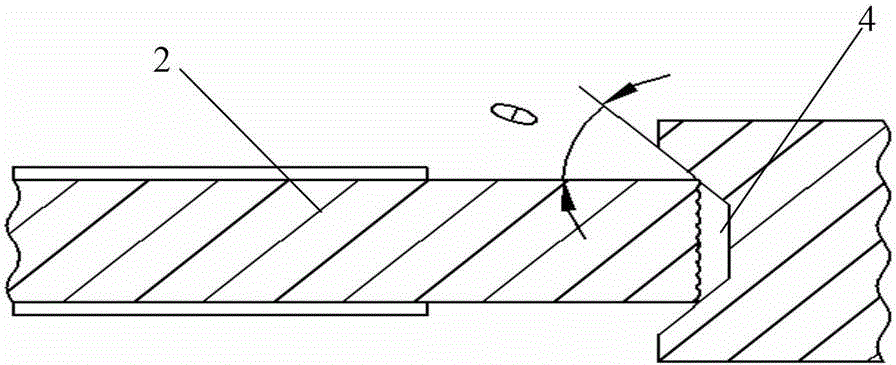

[0036] A kind of semiconductor chip mesa modeling method of the present invention, uses the circular grinding wheel 3 of high-speed rotation, offers the groove 4 corresponding to required groove type on the grinding wheel 3, is plated with diamond in the groove 4, puts on the chip 2 to be processed The cylindrical surface of the chip junction terminal extends into the groove 4, and forms the table top by contacting the groove 4, which can simultaneously shape the double-sided multi-angle, the angle is finely matched, and the efficiency is greatly improved. In this way, when the bevel grinding is performed on the chip 2, the rough end surface produced by cutting the circle is also ground at the same time, so as to avoid chipping and splitting at the edge, and the improvement of the edge condition is conducive to improving the reliabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chamfer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com