Core-shell-structure lithium manganate capable of improving high temperature resistance performance, and synthesis method of core-shell-structure lithium manganate

A structural lithium manganate, high temperature resistant technology, used in structural parts, electrical components, electrochemical generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

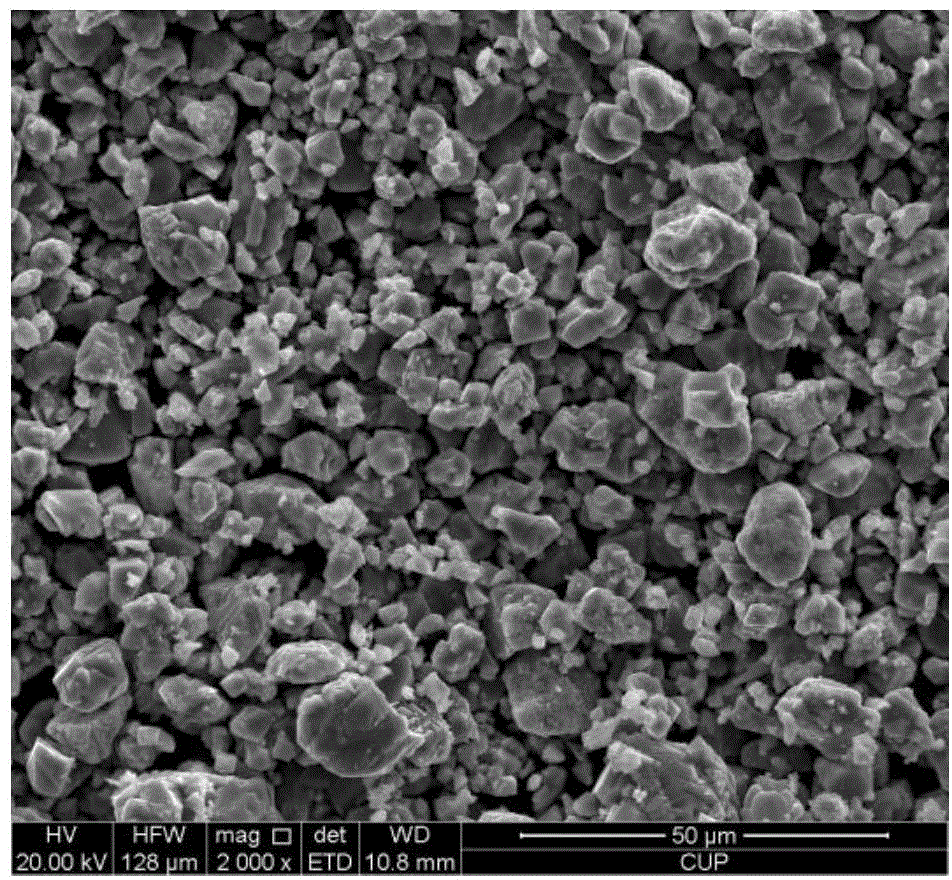

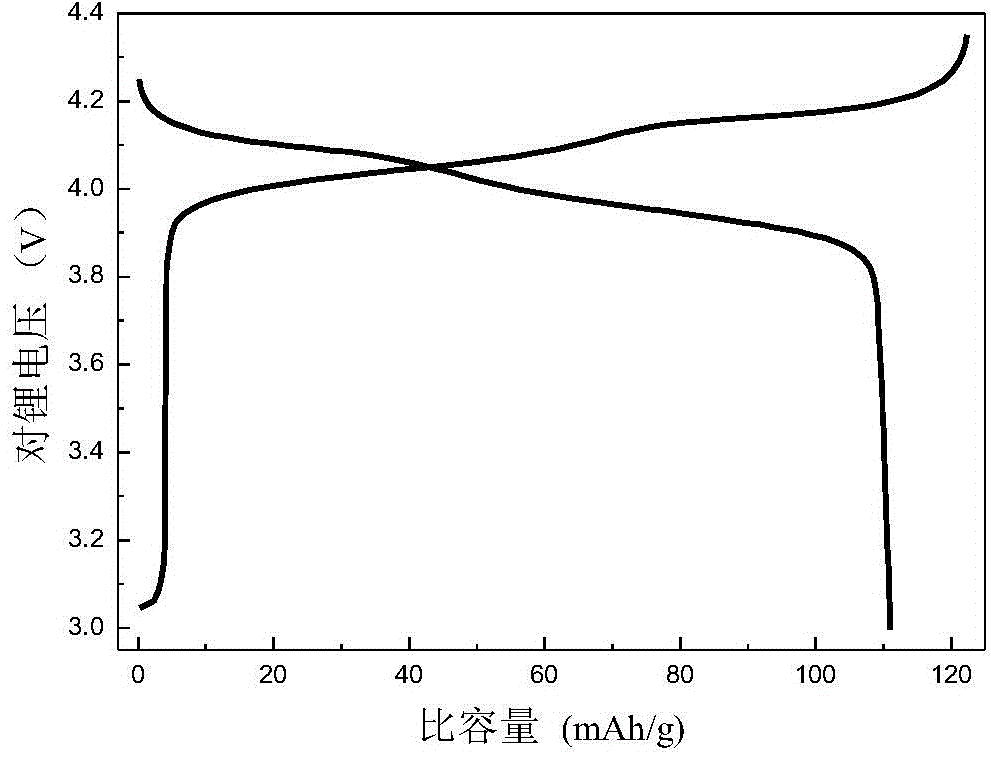

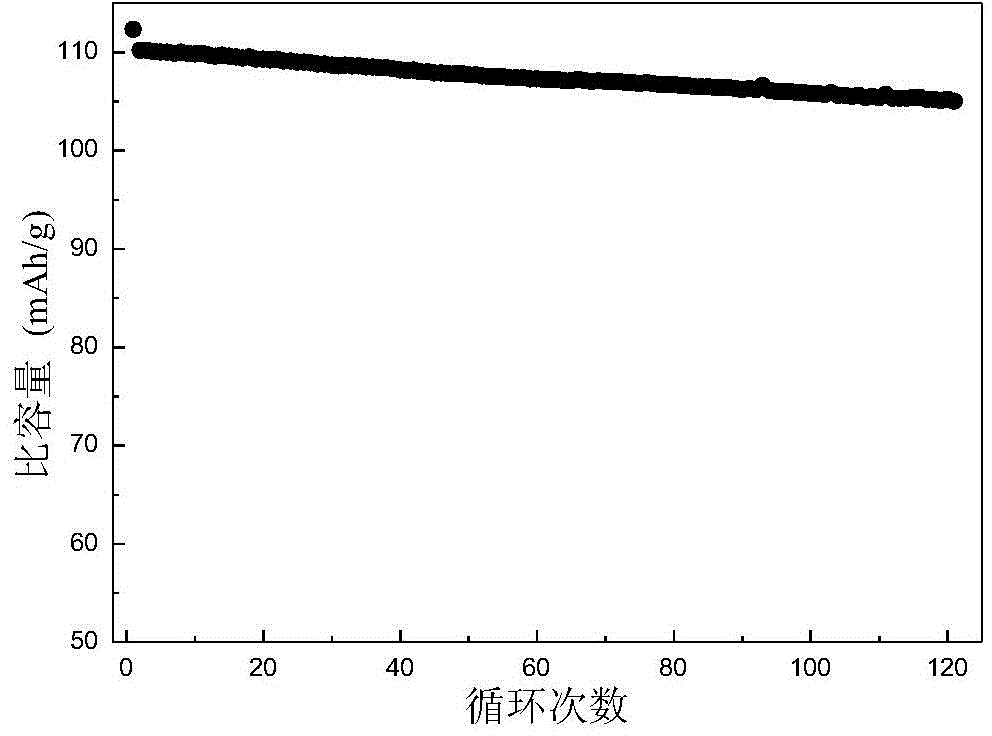

Image

Examples

Embodiment 1

[0032]Mix 100mL of deionized water with 20mL of 25% ammonia water, and add 2mol / L NaOH solution dropwise to it until the pH value is 10.0±0.3, and use this mixed solution as the base solution. 70.11g spherical Mn 3 o 4 Add (the Mn content is 70.52wt%) into the above bottom liquid, use 2mol / L NaOH solution as precipitant to control the pH value to 10.0±0.3, the stirring speed is 800 rpm, and the water bath temperature is 50°C. Under the condition of blowing nitrogen, 1mol / L NiSO was added dropwise 4 , 1mol / L CoSO 4 and 1mol / L MnSO 4 50.1 mL of mixed solution consisting of 16.7 mL each. After the addition is complete, continue to drop the above-mentioned NaOH solution to keep the pH value of the solution at 10.0±0.3, and continue to stir for 0.5h. Wash the precipitate 3 times with 100 mL deionized water, filter and dry to obtain the Mn coated with nickel hydroxide cobalt manganese 3 o 4 Composite material.

[0033] The content of Ni, Co and Mn in the material obtained ab...

Embodiment 2

[0038] Mix 100mL deionized water and 20mL ammonia water with a concentration of 36%, and add 2mol / L NaOH solution dropwise to it until the pH value is 9.30±0.3, and use this mixed solution as the base solution. 70.11g spherical Mn 3 o 4 Add (Mn content is 70.52wt%) into the above bottom liquid, use 2mol / L NaOH solution as a precipitant to control the pH value to 9.30±0.3, the stirring speed is 800 rpm, and the water bath temperature is 50°C. Under the condition of blowing nitrogen, 1mol / L NiSO was added dropwise 4 and 1mol / L CoSO 4 Each 16.7mL solution and 1mol / L Al 2 (SO 4 ) 3 41.8mL mixed solution composed of 8.4mL solution, after the addition is completed, continue to add NaOH dropwise, so that the pH value of the solution remains at 9.30±0.3, and continue to stir for 0.5h. The precipitate was washed 3 times with 100 mL of deionized water, filtered and dried to obtain Mn coated with nickel hydroxide cobalt aluminum 3 o 4 Composite material.

[0039] The content of ...

Embodiment 3

[0044] Mix 100mL of deionized water with 20mL of 36% ammonia water, and add 2mol / L NaOH solution dropwise to it until the pH value is 10.0±0.3, and use this mixed solution as the base solution. 70.11g spherical Mn 3 o 4 Add (the Mn content is 70.52wt%) into the above bottom liquid, control the pH value to 10.0±0.3, the stirring speed is 800 rpm, and the water bath temperature is 50°C. Under the condition of blowing nitrogen gas, 25 mL of NiSO with a concentration of 1 mol / L was added dropwise 4 solution and 75mL of MnSO with a concentration of 1mol / L 4 While the solution was composed of 100mL mixed solution, 2mol / L NaOH solution was added dropwise. To be the above NiSO 4 and MnSO 4 After adding the mixed solution, continue to add NaOH solution dropwise to keep the pH value at 10.0±0.3, and continue to stir for 0.5h. Wash the precipitate 3 times with 100mL deionized water, filter and dry to obtain the nickel hydroxide-coated Mn 3 o 4 Composite material.

[0045] The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com