Externally-cooled electronic condenser

A technology of condenser and electronic refrigeration, which is applied in the direction of laboratory equipment, heating or cooling equipment, chemical instruments and methods, etc., can solve the problem that the cooling effect of electronic condenser is not effectively exerted, the structure of internal condensation electronic condenser is complex, It is not easy to manufacture and process problems, and achieve the effect of simple structure, easy popularization and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

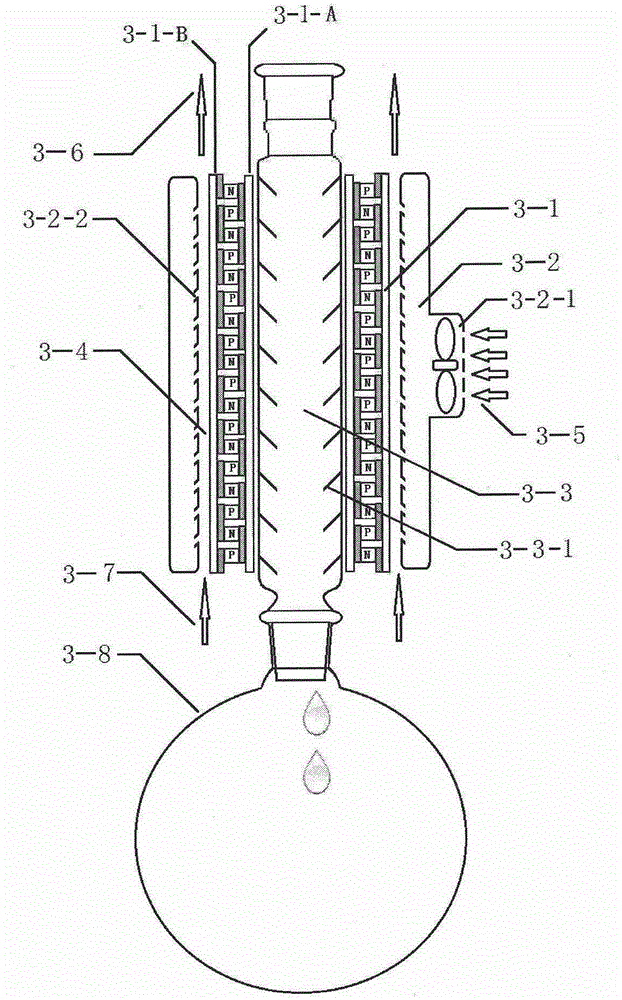

[0027] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

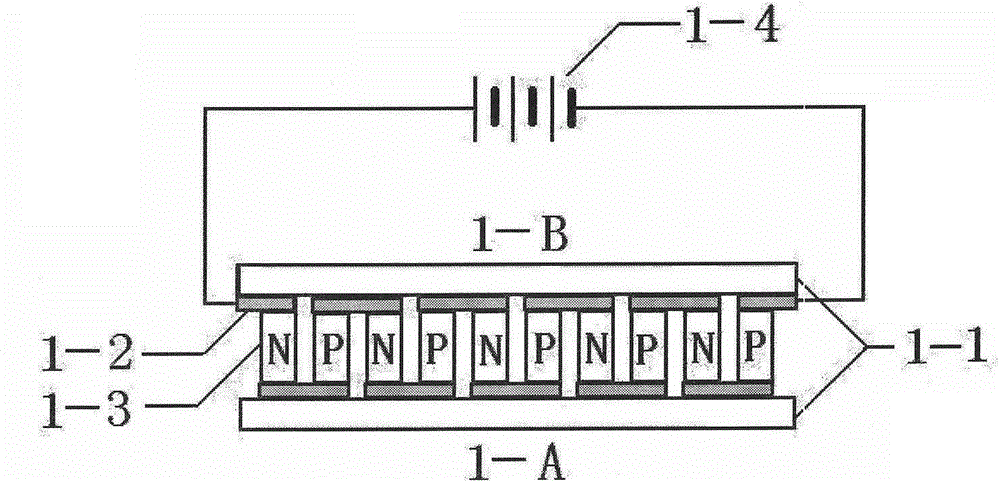

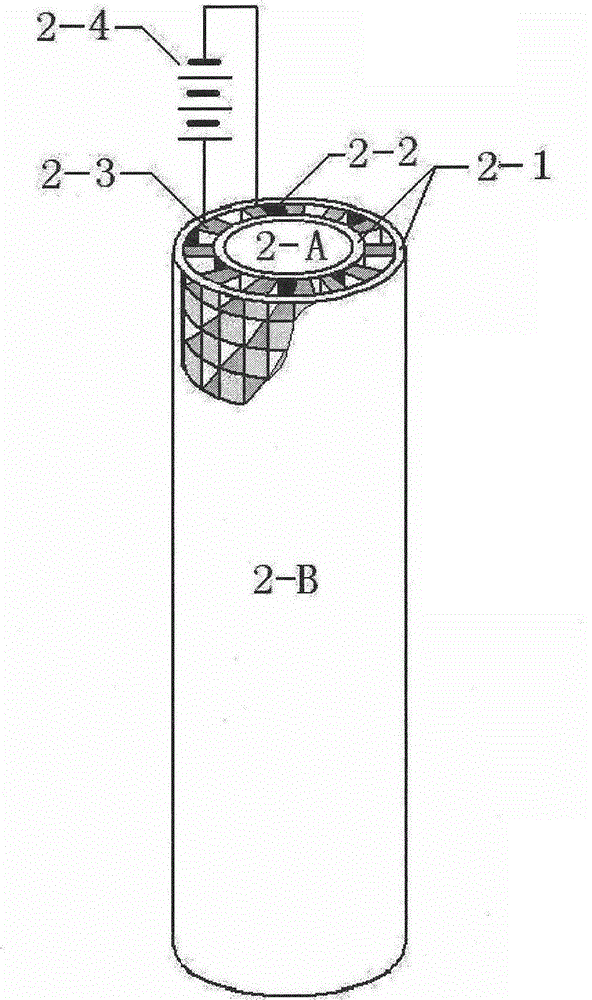

[0028] The structure and working principle of electronic refrigeration components such as figure 1 , figure 2 As shown, 1-1 and 2-1 are insulating ceramics, 1-2 and 2-2 are metal conductors, 1-3 and 2-3 are N-type and P-type semiconductors, and 1-4 and 2-4 are DC power supplies . After the DC power supply is connected to the electronic refrigeration component, energy transfer occurs immediately. The current flows from the N-type component to the P-type component to absorb heat, and the 1-A and 2-A surfaces become the cold end and the temperature decreases; the P-type component flows to the N The joint of the type element releases heat, and the 1-B and 2-B surfaces become the hot end and the temperature increases. Generally, the temperature difference between the hot and cold ends of electronic refrigeration components can reach between 40 and 65 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com