Exhaust system and fermenting barrel

An exhaust system and exhaust pipe technology, applied in the direction of solid waste removal, etc., can solve the problems of gas overflow polluting the environment, easy interruption, gas overflow, etc., and achieve safe and smooth exhaust gas discharge, ingenious structural design, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

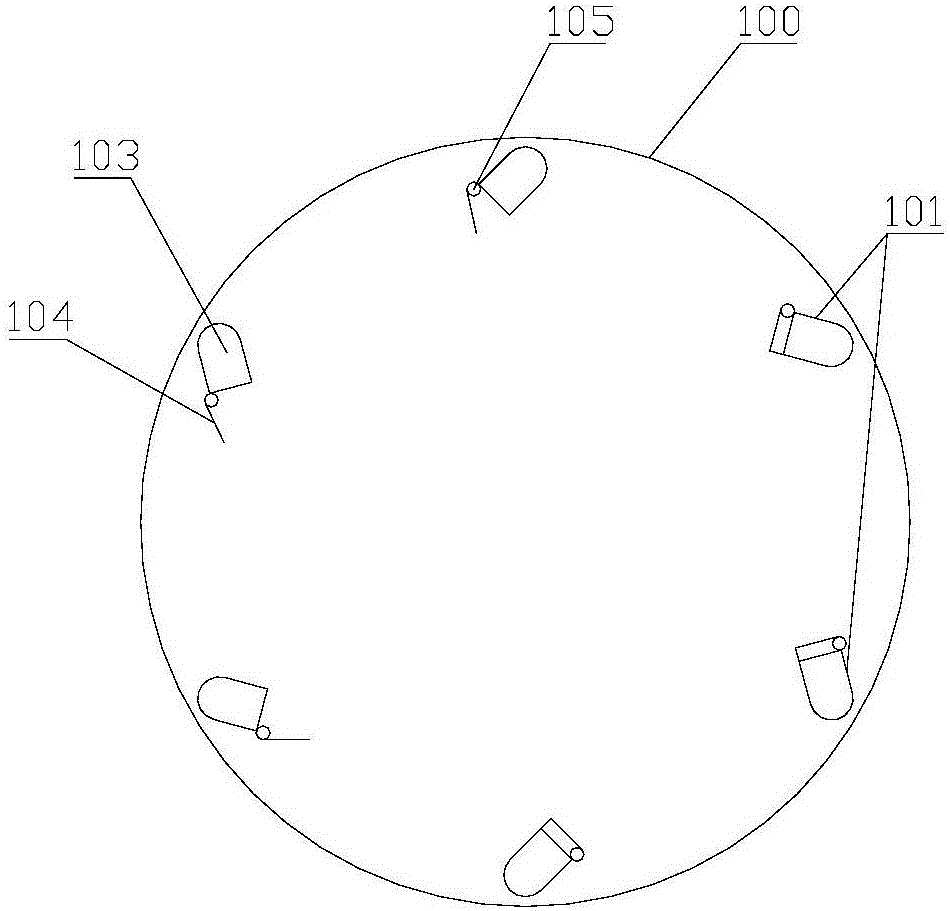

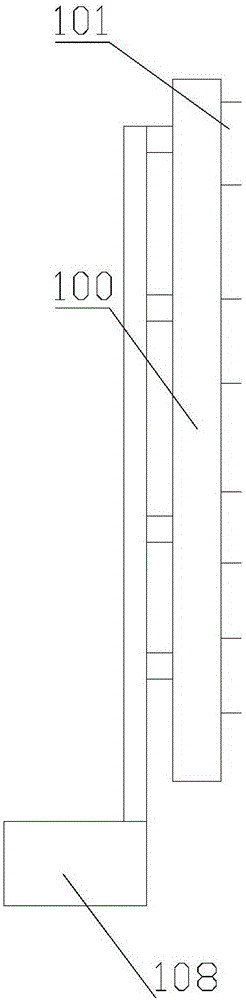

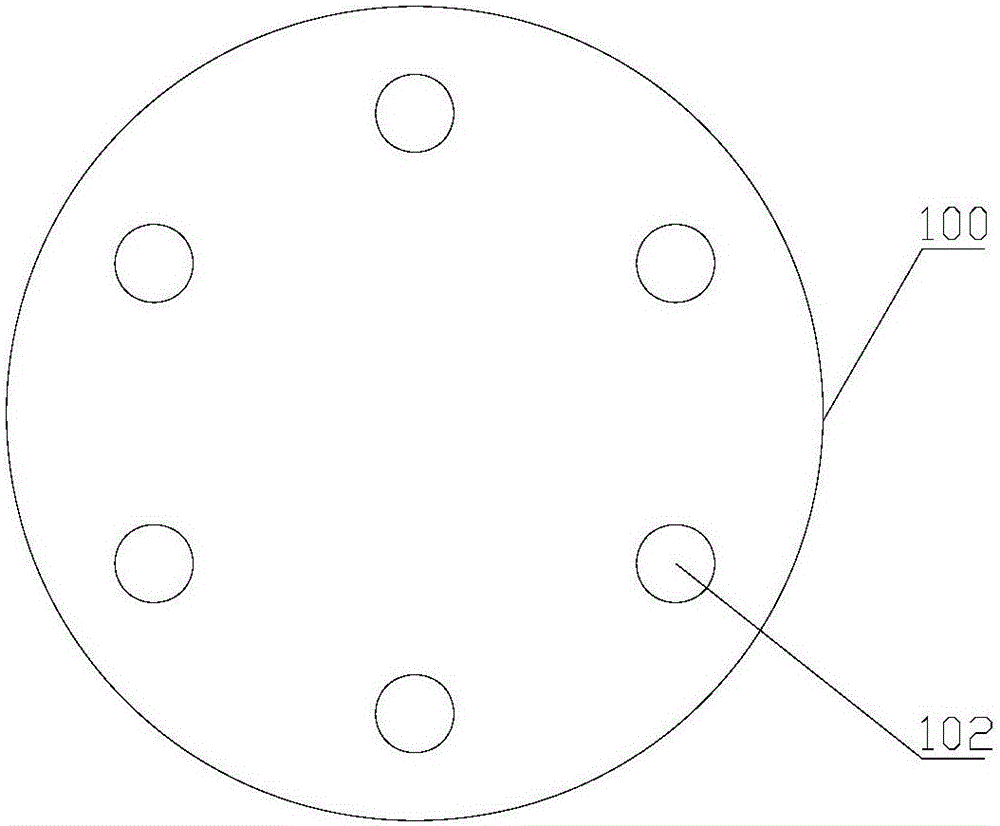

[0037] In people's daily life, restaurants produce a large amount of household waste every day, the most important of which includes leftover food, which is rich in organic matter, and if not handled properly, it is easy to rot in the air, emit an unpleasant smell, pollute the air and the environment . The existing technology mainly adopts fermentation treatment for food waste, that is, the existing restaurant waste is poured into a bucket equipped with electric heating and stirring rod after pretreatment such as draining, crushing and dehydration, and then heated, stirred, Drying treatment, and after being placed in the heating cylinder for a period of time, it is taken out, packaged in a packaging bag, and then decomposed and fermented. The equipment used for fermentation is equipped with an exhaust system, which can discharge the waste gas in the fermentation cylinder, while the exhaust system in the prior art is a simple through hole, which communicates the through hole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com