Method for reducing carbendazim impurity DAP in production process of carbendazim

A production process and technology of carbendazim, applied in the field of carbendazim production, can solve the problem of high DAP content and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

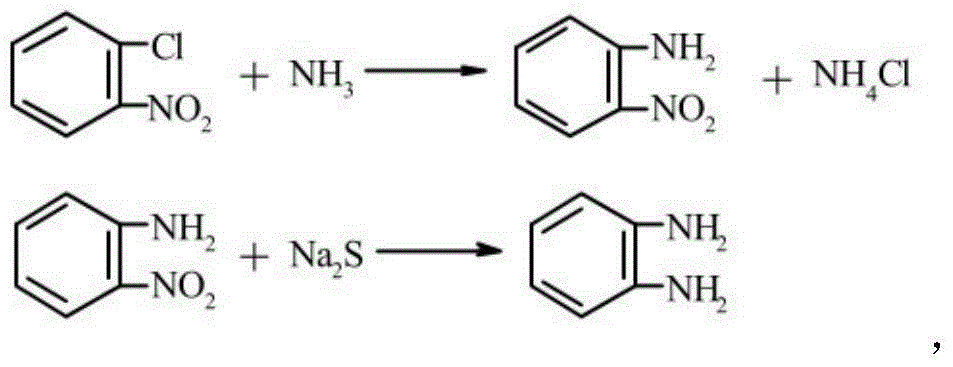

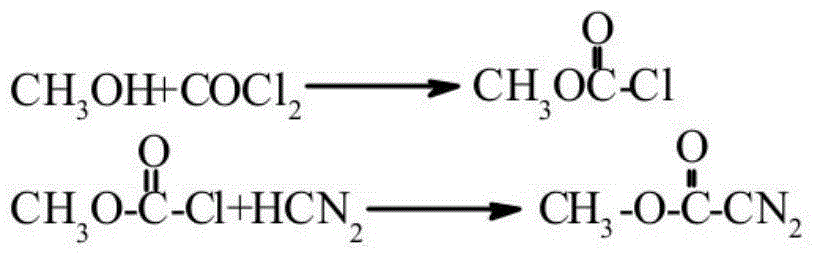

[0018] First carry out the synthesis of o-phenylenediamine; carry out the synthesis of methyl cyanamide; then carry out the synthesis of carbendazim: o-phenylenediamine and methyl cyanamide are transferred to the reactor for complexation reaction, and Add dropwise hydrochloric acid while the complexation reaction, and dropwise add hydrochloric acid at the end of the condensation, the pH in the reactor is 4.2 at this time, and relatively stable, then add 2.5kg of additive paraformaldehyde in the reactor, open the reactor stirring device to fully Stir, keep warm, and the temperature is 98 ° C, the holding time is 60 minutes, then filter the materials in the reactor, wash the filtered materials with water, then drain the washed materials, and finally drain the dried materials After drying, the DAP content reaches about 0.5ppm after rectification, and DAP does not rebound after being placed overnight, which can better meet the production requirements, that is, add additional additi...

Embodiment 2

[0020] First carry out the synthesis of o-phenylenediamine; carry out the synthesis of methyl cyanamide; then carry out the synthesis of carbendazim: o-phenylenediamine and methyl cyanamide are transferred to the reactor for complexation reaction, and Add hydrochloric acid dropwise while the complexation reaction, and drop hydrochloric acid at the end of condensation, at this moment, the pH in the reactor is 4.3, and relatively stable, then add the additive paraformaldehyde of 2.4kg in the reactor, open the reactor stirring device to carry out fully Stir, keep warm, and the temperature is 96°C, the holding time is 40min, then filter the material in the reactor, wash the filtered material with water, then drain the washed material, and finally drain the dried material After drying, the DAP content can reach about 0.5ppm after rectification, and the DAP will not rebound after being left overnight, which can better meet the production requirements, that is, add additives after the...

Embodiment 3

[0022] First carry out the synthesis of o-phenylenediamine; carry out the synthesis of methyl cyanamide; then carry out the synthesis of carbendazim: o-phenylenediamine and methyl cyanamide are transferred to the reactor for complexation reaction, and Add hydrochloric acid dropwise while the complexation reaction, and drop hydrochloric acid at the end of the condensation, the pH in the reactor is 4.4 at this time, and relatively stable, then add 2.3kg of additive paraformaldehyde in the reactor, open the reactor stirring device to fully Stir, keep warm, and the temperature is 95 ° C, the holding time is 30 minutes, then filter the materials in the reaction kettle, wash the filtered materials with water, then drain the washed materials, and finally drain the dried materials After drying, the DAP content reaches about 0.5ppm after rectification, and DAP does not rebound after being placed overnight, which can better meet the production requirements, that is, add additional additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com