A compound processing and forming method for metal blanks

A technology for composite processing and blank parts, which is applied in the direction of metal material coating process, process efficiency improvement, coating, etc. The effect of miniaturization and miniaturization, production cost saving, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

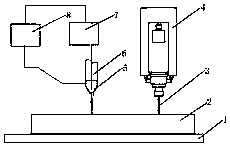

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0024] The specific implementation steps of this embodiment are as follows:

[0025] a. Casting to obtain the part blank 2;

[0026] b. According to the precision requirements, shape characteristics and other factors of the part blank 2, as well as the stroke of the processing equipment and cladding equipment, divide the part blank 2 to determine the processing area and cladding area;

[0027] c. For different areas, write their respective CNC machining codes and laser cladding codes;

[0028] d. Prefabricated metal alloy powder for cladding;

[0029] e. Place the part blank 2 on the platform 1 of the compound processing machine tool;

[0030] f. According to the CNC machining code, drive the machining spindle 4 to perform CNC machining operations on the part blank 2; according to the claddin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com