A kind of wheat bran microcrystalline cellulose and its preparation method

A technology of microcrystalline cellulose and cellulose, applied in the field of utilization of agricultural and forestry biomass resources, can solve the problems of harsh extraction conditions, harsh reaction conditions, and low product yields, and achieve rich raw material sources, less harsh use conditions, and high extraction rates. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

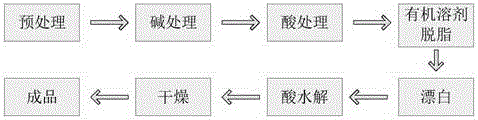

[0079] figure 1 For the process flow diagram of the preparation method of wheat bran microcrystalline cellulose of the present invention, refer to figure 1 , the present embodiment provides a preparation method of wheat bran microcrystalline cellulose, comprising the following steps:

[0080] (1) Pretreatment: Grind the wheat bran with a pulverizer, then pass through a 100-mesh sieve to obtain wheat bran residue, add distilled water to the wheat bran residue at a temperature of 70°C according to the ratio of solid to liquid at 1:10g / mL Cooking pretreatment for 20 minutes, cooling to room temperature, filtering the cooked wheat bran residue to obtain the first filter residue;

[0081] (2) Alkali treatment: the first filter residue is added to the NaOH solution with a mass fraction of 1% according to the solid-liquid ratio of 1:10g / mL, and the leaching temperature is 80°C for 12h, and then the leaching After the first filter residue is washed to neutrality, it is filtered to o...

Embodiment 2

[0090] A preparation method of wheat bran microcrystalline cellulose, comprising the following steps:

[0091] (1) Pretreatment: Grind the wheat bran with a pulverizer, and pass through a 100-mesh sieve to obtain the wheat bran residue. Add distilled water to the wheat bran residue at a temperature of 60°C according to the solid-liquid ratio of 1:15g / mL. Cooking pretreatment for 15 minutes, cooling to room temperature, filtering the cooked wheat bran residue to obtain the first filter residue;

[0092] (2) Alkali treatment: the first filter residue is added to a NaOH solution with a mass fraction of 3% according to a material-to-liquid ratio of 1:15g / mL, and the leaching temperature is 40°C for 48 hours, and then the leaching After the first filter residue is washed to neutrality, it is filtered to obtain the second filter residue;

[0093] (3) Acid treatment: add distilled water to the second filter residue according to the solid-liquid ratio of 1:3g / mL, and adjust the pH to...

Embodiment 3

[0099] A preparation method of wheat bran microcrystalline cellulose, comprising the following steps:

[0100] (1) Pretreatment: Grind the wheat bran with a pulverizer, and pass through a 100-mesh sieve to obtain the wheat bran residue. Add distilled water to the wheat bran residue at a temperature of 80°C according to the ratio of solid to liquid at 1:20g / mL. Cooking pretreatment for 10 minutes, cooling to room temperature, filtering the cooked wheat bran residue to obtain the first filter residue;

[0101](2) Alkali treatment: the first filter residue is added to the NaOH solution with a mass fraction of 5% according to the ratio of material to liquid of 1:20g / mL, and the leaching temperature is 60°C for 36h, and then after leaching The first filter residue is washed to neutrality, and filtered to obtain the second filter residue;

[0102] (3) Acid treatment: Add distilled water to the second filter residue according to the solid-liquid ratio of 1:4g / mL, adjust the pH to 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com