Off-axis parabolic mirror key parameter calibration system and method

A technology for off-axis parabolic mirrors and key parameters, which is applied in the field of calibration methods and systems for key parameters of off-axis parabolic mirrors, and can solve the problems of low off-axis angle measurement accuracy and easy scratching of off-axis parabolic mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

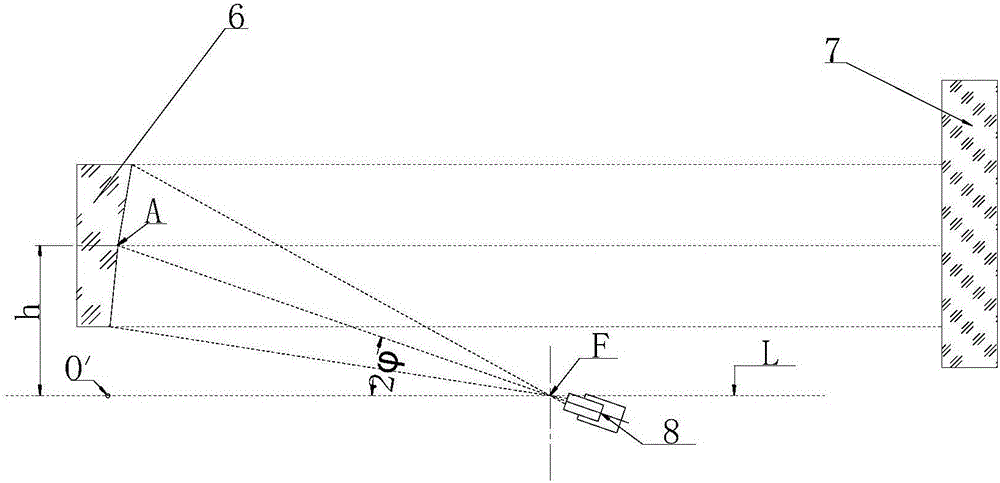

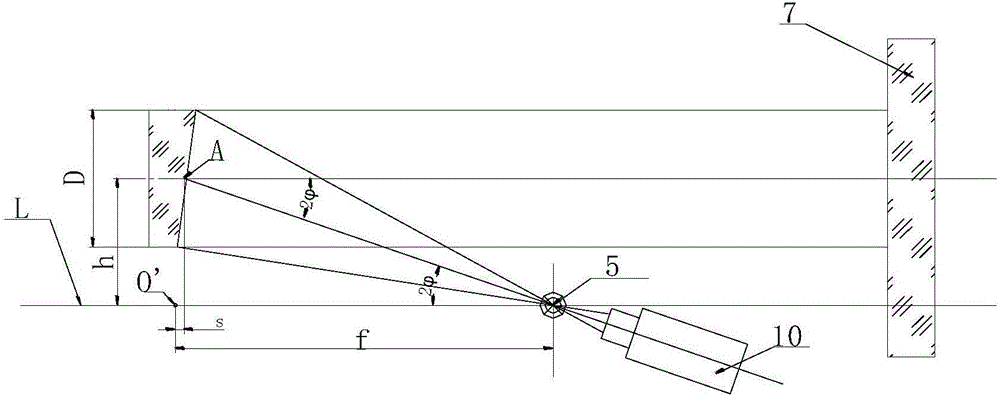

[0065] Such as image 3 As shown, the interferometric autocollimation detection optical path is built by using the laser interferometer, the plane mirror and the tested off-axis parabolic mirror, and the spatial position relationship of the three is accurately calibrated to obtain accurate interference detection data. At this time, the focal point of the converging beam emitted by the laser interferometer coincides with the focal point of the off-axis parabolic mirror completely, and the beam emitted by the laser interferometer is reflected by the off-axis parabolic mirror and is vertically incident on the plane mirror and returns along the original path.

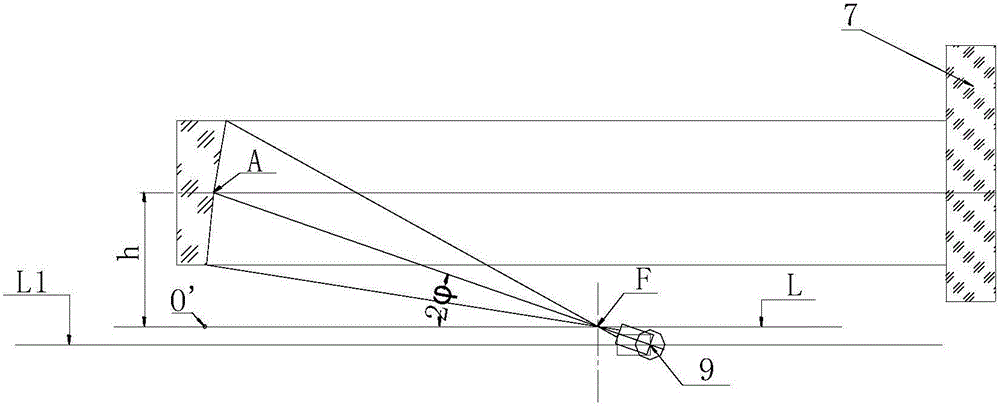

[0066] Such as Figure 4 As shown, place a reference cross target at the place where the focus of the off-axis parabolic mirror and the laser interferometer coincide. The center of the cross target coincides with the focus and is located on the original optical axis. Theodolite 1 and the plane reflector are self-aligned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com