Solder distribution of semiconductor device heat radiation module

A technology for heat dissipation modules and semiconductors, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve problems such as chip short circuit and short circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

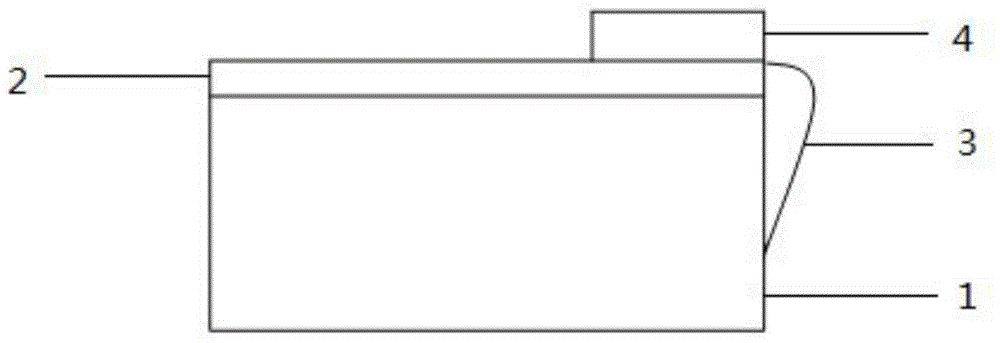

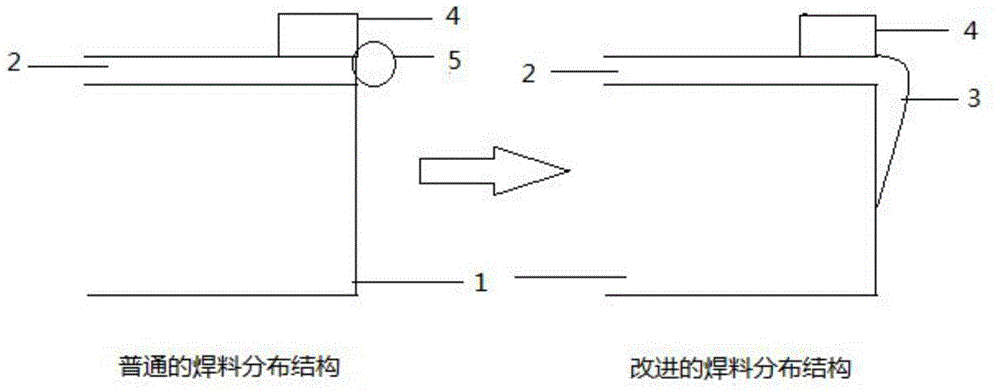

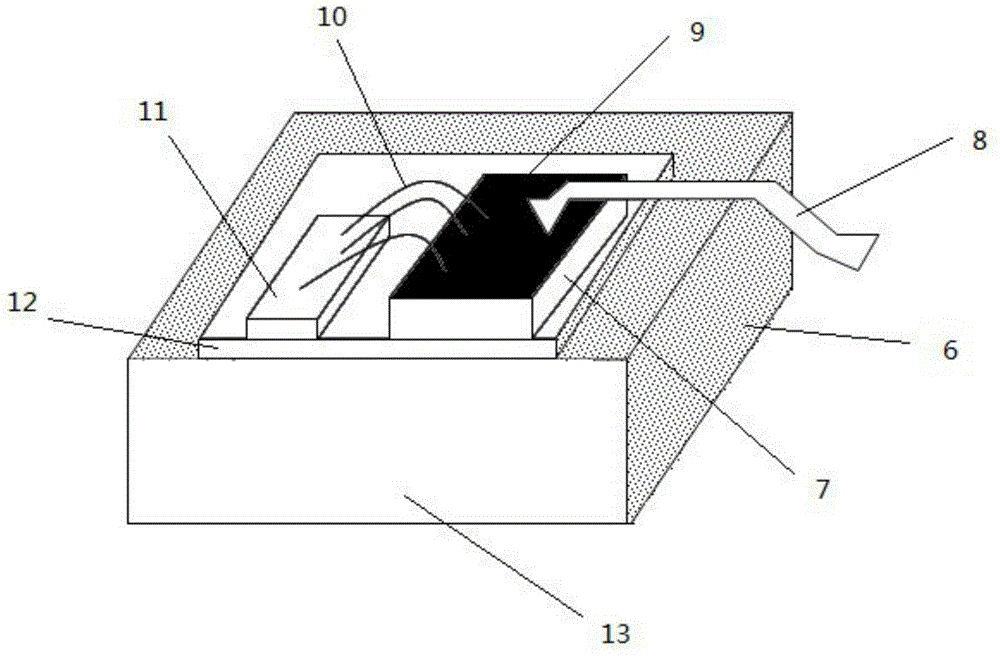

[0018] The improved solder distribution structure of the semiconductor device provided by the present invention provides a specific implementation mode. Taking a semiconductor laser as an example, indium is used as solder and sintered on a copper heat sink, including:

[0019] S1 cleans the copper heat sink (6), thereby removing the copper oxide on the surface of the copper heat sink (6), and rinses it with deionized water after cleaning;

[0020] S2 places the cleaned copper heat sink (6) on the evaporation table, and evaporates a layer of gold on the surface of the copper heat sink (6);

[0021] S3 places the copper heat sink (6) with a gold layer evaporated on its surface in the indium plating solution, and uses an electrochemical method to place a die on the gold-plated copper heat sink (6) while evaporating a layer of the first indium layer ( 12);

[0022] S4 According to the electrochemical method described in S3 above, use a specific fixture to vapor-deposit a second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com