Microstrip planar spiral filter and design method thereof

A planar spiral and filter technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of difficult implementation, large volume, and high cost, and achieve the effects of wide passband range, small volume, and low cost

Inactive Publication Date: 2015-10-07

NANJING HENGDIAN ELECTRONICS

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are many kinds of existing microwave filters, among which the air cavity filter and the waveguide filter are bulky, costly, and heavy; the micromechanical silicon cavity filter is complex in process and high in cost; It occupies a large area; although the area of the comb filter is small, its loading capacitance is not easy to realize; the passband frequency of the surface acoustic wave filter is not high; microwave filters of other structures or shapes have large volume or large area or bandwidth Disadvantages such as too narrow or difficult to implement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

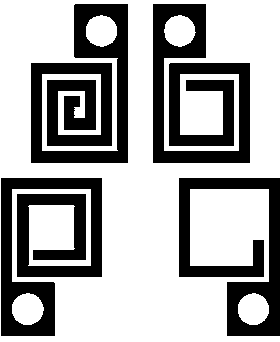

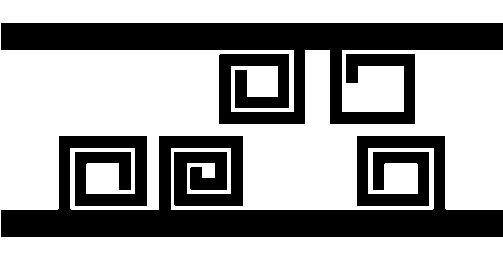

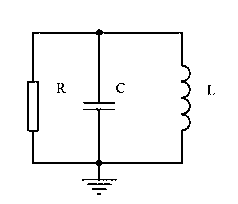

The invention relates to a microstrip planar spiral filter comprising N resonant cavities which are distributed on the same microstrip circuit board, wherein N is a positive integer, and the resonant cavities are formed by microstrip planar spiral resonators. The N-order coupled resonant cavity filter is realized by N microstrip planar spiral resonators through mutual coupling. Coupling strength of direct coupling between the two adjacent resonators is confirmed by distance between the adjacent resonators. Coupling intensity of capacitive coupling between the non-adjacent resonators is adjusted by inserting a microstrip line, and the shape of the inserted microstrip line is pi-shaped or H-shaped. Resonant frequency of all the microstrip planar spiral resonators, coupling intensity between the resonators and the loaded Q value inputted to and outputted from the resonators are adjusted by the aforementioned method. The designed microstrip planar spiral filter is small in size, small in area, light in weight and relatively wide in passband range and can be realized by adopting a printed circuit board technology or a thin-film technology so as to be low in cost and suitable for almost all microwave frequency bands.

Description

technical field The invention relates to the technical field of microwave filters, in particular to a microstrip planar helical filter and a design method thereof. Background technique There are many types of existing microwave filters, among which air cavity filters and waveguide filters are bulky, costly, and heavy; micromechanical silicon cavity filters are complex and costly; interdigital filters with microstrip structures It occupies a large area; although the area of the comb filter is small, its loading capacitance is not easy to realize; the passband frequency of the surface acoustic wave filter is not high; microwave filters of other structures or shapes have large volume or large area or bandwidth Disadvantages such as being too narrow or difficult to implement. Contents of the invention The technical problem to be solved by the present invention is to provide a microstrip planar spiral filter, which is small in size, small in area, light in weight, and has a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01P1/203H01P11/00

Inventor 曾运华杨振锋

Owner NANJING HENGDIAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com