Integral high-voltage-cable anti-explosion joint box

A technology for high-voltage cables and cable joints, applied in the direction of cable joints, etc., can solve problems such as damage to protective layer, flashover fire, aging of insulating materials, etc., to achieve the effect of high strength and prevention of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

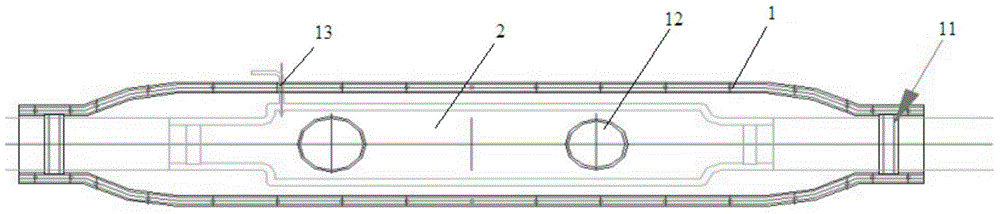

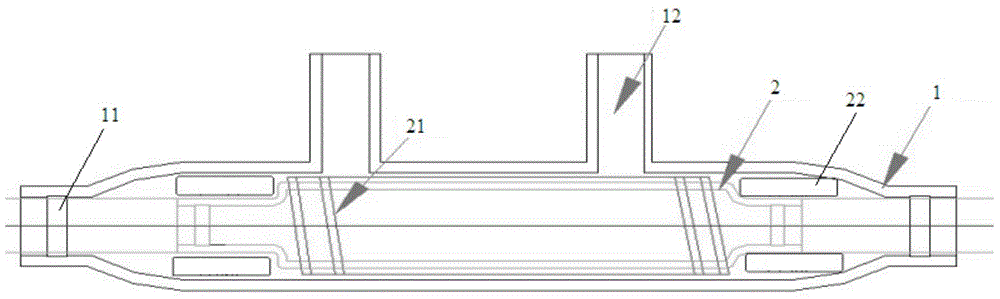

[0035] like figure 1 and 2 As shown, an integral high-voltage cable explosion-proof joint box is used to protect the safety of high-voltage cable joints in underground cable channels. The explosion-proof fire extinguishing assembly inside the explosion-proof chamber in the middle of the body 1. The shell 1 is a shuttle-shaped symmetrical structure, with cable holes at both ends, and a seal 11 is provided at the cable hole. There is also a cable connector 2 inside the explosion-proof chamber in the middle. The explosion-proof fire extinguishing assembly and The cable joint 2 is connected, and the housing 1 is also provided with a plurality of energy-discharging hole guide pipes 12 communicating with the central explosion-proof chamber, and the rest of the space inside the central explosion-proof chamber is filled with fire-proof, heat-insulating and flame-retardant materials.

[0036] The explosion-proof fire extinguishing assembly includes an induction wire harness 21 sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com