Sensor apparatus for determining at least one rotation property of a rotating element

A technology of sensor devices and rotating components, applied in the direction of converting sensor output, using electric/magnetic devices to transfer sensing components, measuring devices, etc., can solve the problem of speed sensor not providing accuracy, etc., and achieve the effect of improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

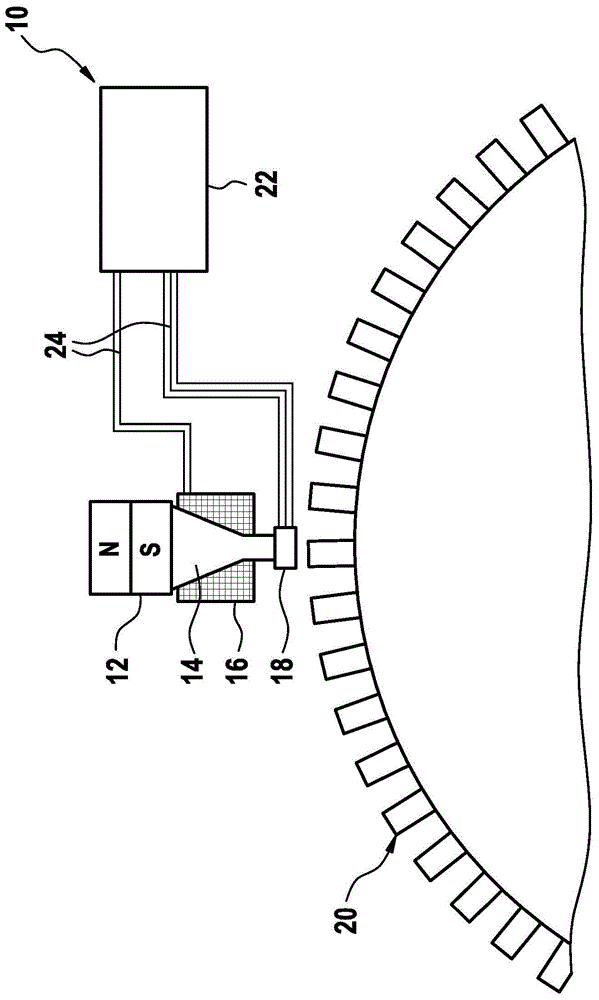

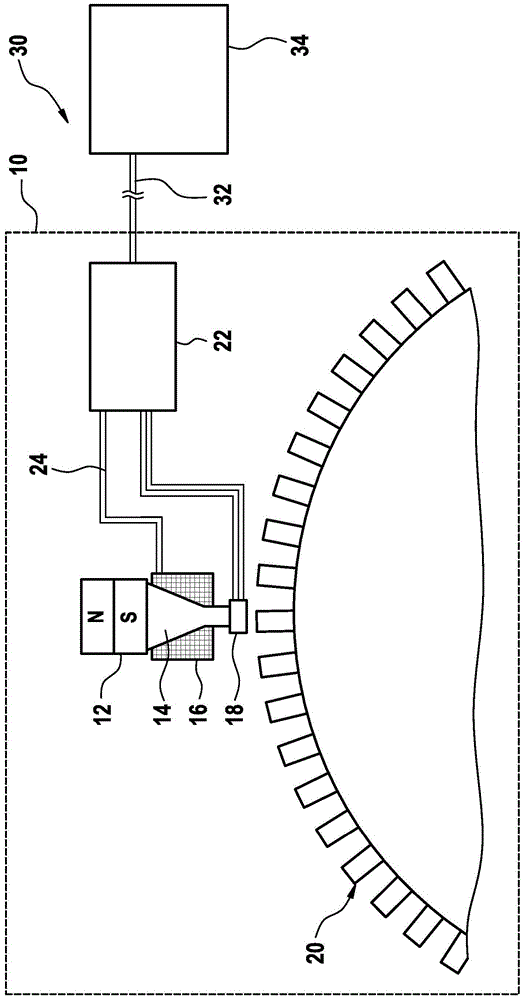

[0030] if available from figure 1 The illustrated embodiment of the sensor device 10 has a magnetic field generator 12, which can be formed, for example, by a permanent magnet. As shown, the sensor device 10 further comprises a flow guide element 14 which is arranged in the form of a surface on the south pole of the magnetic field generator 12 shown as a dipole magnet, which flow guide element is simultaneously directed in the direction of the rotating element (not shown). extend. Here, as an alternative, the magnetic field generator 12 can also be provided with a polarity orientation opposite to that of the components shown.

[0031] Furthermore, a first magnetic sensor 16 is arranged, preferably in the form of a coil 16 surrounding the flow guide element 14, and a second magnetic sensor 18 is arranged, preferably in the direction of the flow guide element 14 on the end face of the rotating element. Here, preferably, the second magnetic sensor 18 is not surrounded by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com