Machining technology of open structure part

A technology for processing technology and structural parts, which is applied in the field of processing technology for open structural parts, can solve the problems of low efficiency and high difficulty in processing open structural parts, and reduce the rate of waste and defective products, improve the qualified rate and surface processing quality , The effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

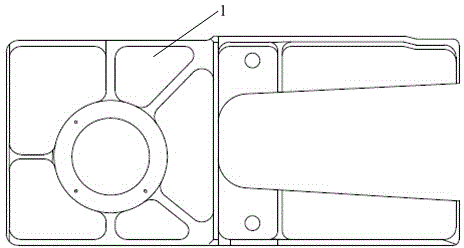

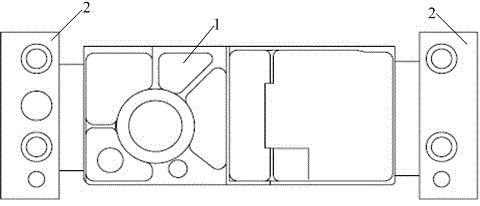

[0030] attached figure 1 It is the front view of a typical open part 1, the material is LC9CGS3 (free forging) aluminum alloy, the bottom surface and the web surface of the part are curved surfaces, there are many ribs in the inner cavity of the front end of the part to strengthen the part, and the tail of the part is an open structure.

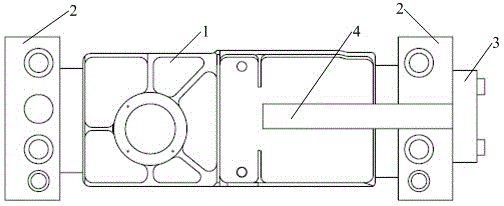

[0031] The key to the processing technology of open structural parts is to find the most obvious deformation part of part 1 and effectively control the deformation amount of this part during processing. Refer to attached figure 1 It can be seen that the part with the largest deformation of the part lies in the opening of the tail of the part, and the process patch is redesigned according to the structural characteristics of the part. The patch overlapping method is to place the patch in the length direction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com