Environment-friendly energy-saving heating system for hot press

An environmental protection, energy saving, heating system technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high equipment price and pollution, and achieve the effect of improving equipment safety, reducing safety hazards, and solving the problem of heat transfer oil expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

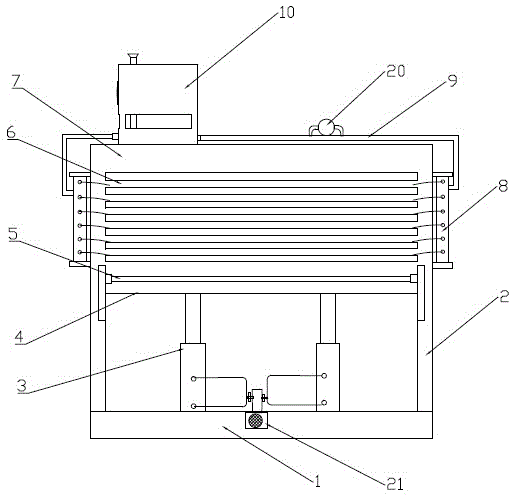

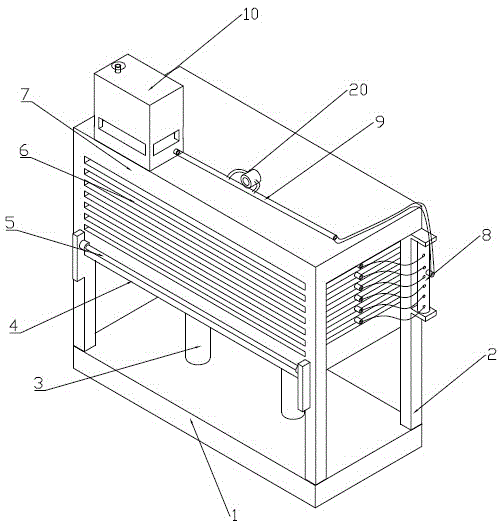

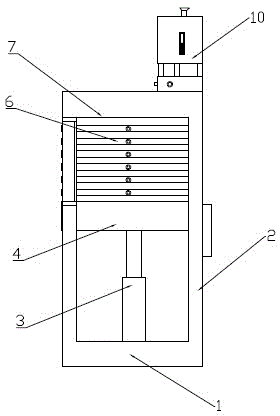

[0028] Embodiment one : see Figures 1 to 6 , an environmental protection and energy-saving heating system for a hot press, including a hot press and a heating device. The hot press includes an upper pallet 7, a lower pallet 4, a hot press frame 2 and a Between the heating plate 6, the two ends of the heating plate are provided with heat transfer oil inlet and outlet 14, 19, and the heat transfer oil inlet and outlet 14, 19 are connected with the heat transfer oil shunt pipe 8 fixed on both sides of the hot press frame, and the heat transfer oil is provided by the heating device. 10 The heat transfer oil outlet 19 enters the heat transfer oil distribution pipe, and after passing through the multi-layer heating plate 6, it merges into the heat transfer oil distribution pipe at the other end. Driven by the circulation pump 20, it returns to the heating device 10 from the heat transfer oil inlet 14; The heating box 11 and the telescopic bag 12 are formed. The heating box is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com