High-conductivity thermal-treatment type medium-strength aluminum alloy conducting filament

A technology of aluminum alloy monofilament and high conductivity, which is applied in the direction of metal/alloy conductors, root rods/rods/wires/strip conductors, etc., can solve the problems of high cost, complicated production process, and low conductivity of products, and achieve improved intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

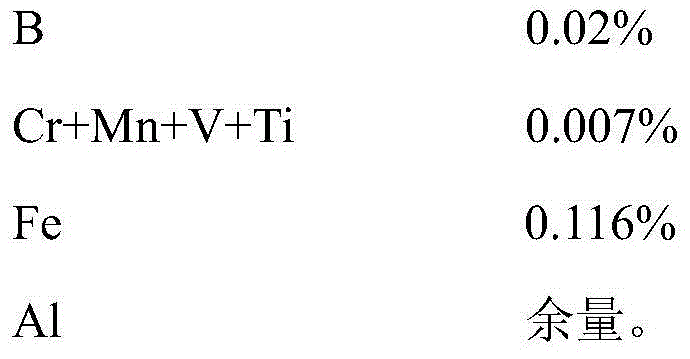

[0044] The composition and mass percentage of the heat-treated medium-strength aluminum alloy conductive monofilament with high conductivity are:

[0045]

[0046]

[0047] Each alloying element is added to an industrially pure aluminum ingot with a purity of 99.7%, so that their final contents are as shown above. Alloying elements B, Si, and Cu are added in the form of Al-B, Al-Si, and Al-Cu master alloys, and alloying element Mg is added in the form of pure metal Mg. The aluminum alloy ingot is formed by casting in a copper mold; the aluminum alloy ingot is hot-rolled by a rolling mill, and the rolled aluminum alloy round rod adopts a conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the wire is drawn on a high-speed wire drawing machine. The aluminum alloy monofilament has a diameter of 3.60 mm, an electrical conductivity of 59.26% IACS, a tensile strength of 245.2 MPa, and an elongation of 4.4%.

Embodiment 2

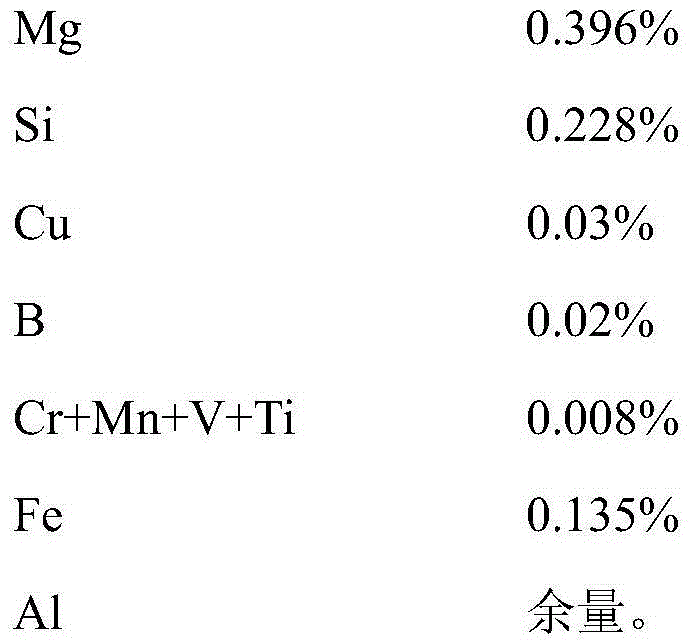

[0049] The composition and mass percentage of the heat-treated medium-strength aluminum alloy conductive monofilament with high conductivity are:

[0050]

[0051] Each alloying element is added to an industrially pure aluminum ingot with a purity of 99.7%, so that their final contents are as shown above. Alloying elements B, Si, and Cu are added in the form of Al-B, Al-Si, and Al-Cu master alloys, and alloying element Mg is added in the form of pure metal Mg. The aluminum alloy ingot is formed by casting in a copper mold; the aluminum alloy ingot is hot-rolled by a rolling mill, and the rolled aluminum alloy round rod adopts a conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the wire is drawn on a high-speed wire drawing machine. The aluminum alloy monofilament has a diameter of 3.60 mm, an electrical conductivity of 59.42% IACS, a tensile strength of 248.4 MPa, and an elongation of 4.2%.

Embodiment 3

[0053] The composition and mass percentage of the heat-treated medium-strength aluminum alloy conductive monofilament with high conductivity are:

[0054]

[0055]

[0056] Each alloying element is added to an industrially pure aluminum ingot with a purity of 99.7%, so that their final contents are as shown above. Alloying elements B, Si, and Cu are added in the form of Al-B, Al-Si, and Al-Cu master alloys, and alloying element Mg is added in the form of pure metal Mg. The aluminum alloy ingot is formed by casting in a copper mold; the aluminum alloy ingot is hot-rolled by a rolling mill, and the rolled aluminum alloy round rod adopts a conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the wire is drawn on a high-speed wire drawing machine. The aluminum alloy monofilament has a diameter of 3.84 mm, an electrical conductivity of 59.49% IACS, a tensile strength of 246.3 MPa, and an elongation of 4.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com