Heat-preservation heat isolation panel with VIP

A technology of vacuum insulation board and thermal insulation board, which is applied in the directions of heat preservation, heat preservation, and protection of pipelines through heat insulation, etc., can solve the problems of high thermal conductivity and cannot meet the actual use requirements, and achieves low shrinkage deformation, enhanced mechanical strength, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

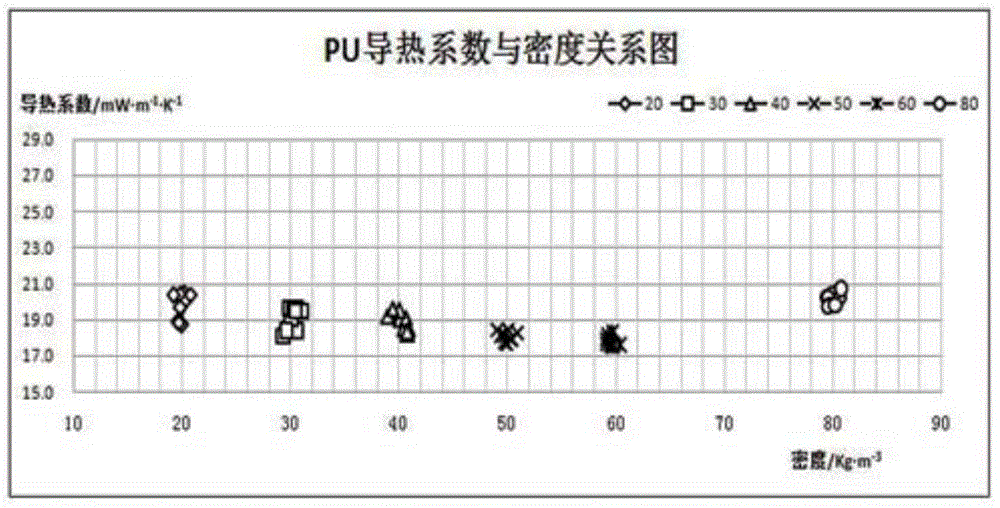

[0040] The cross-sectional structure of the first embodiment of the thermal insulation panel with the vacuum insulation panel of the present invention, as Figure 5 As shown, the thermal insulation panel is composed of a vacuum insulation panel 1 and a porous foam body 2 . The present invention does not limit the type and specification of the vacuum insulation panel 1, and the thickness of the vacuum insulation panel 1 is 5-30 mm. Vacuum insulation panels 1 can be selected from all types commonly used on the market. The porous foam 2 is a rigid polyurethane foam with a density of 40 kg / m3, and the porous foam 2 is in direct contact with and bonded to the main surface 12 of the underside of the vacuum insulation panel 1 and all four sides during the foaming process. In one body; while the main surface 11 on the upper side of the vacuum insulation panel 1 is flush with the upper surface 21 of the porous foam body 2 and exposed to the outside. The lower surface 22 and sides of ...

Embodiment 2

[0044] The cross-sectional structure of the second embodiment of the thermal insulation panel with the vacuum insulation panel of the present invention, such as Image 6 As shown, the thermal insulation panel is composed of a vacuum insulation panel 1' and a porous foam body 2'. The porous foam 2' is a rigid polyurethane foam with a density of 53 kg / m3, and the porous foam 2' is directly in contact with the upper and lower main surfaces 11', 12 of the vacuum insulation panel 1' during the foaming process. 'and all four sides are in contact and integrated; the upper surface 21', lower surface 22' and all sides of the porous foam body 2' are exposed. The closed cell ratio of the porous foam 2' is greater than 90%; the thickness of the porous foam 2' outside the upper and lower main surfaces 11', 12' of the vacuum insulation panel 1' is 5 mm.

[0045] In actual production, the rigid polyurethane porous foam 2' can be either mechanically foamed or manually foamed, as long as the ...

Embodiment 3

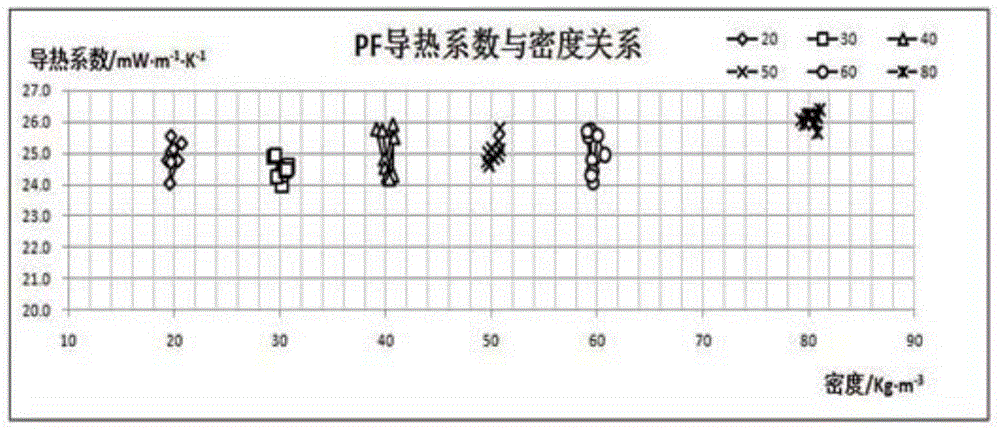

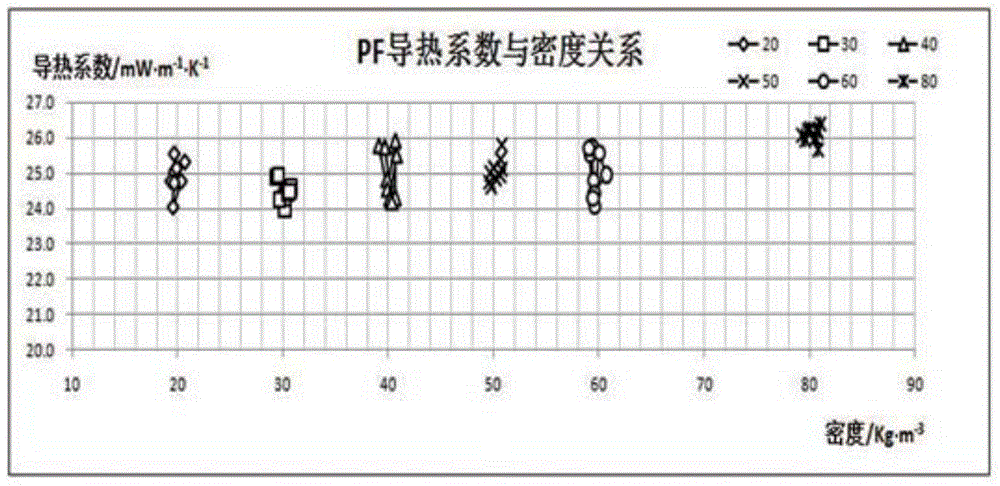

[0048] The present invention has the sectional structure of the thermal insulation panel embodiment of vacuum insulation panel, as Figure 7 As shown, the thermal insulation panel is composed of a vacuum insulation panel 10 , a porous foam body 20 and a rigid decorative material layer 30 . The vacuum insulation panel 10 can be selected from all types commonly used in the market, and the thickness is 5-30 mm. The porous foam 20 is a phenolic resin foam with a density of 35 kg / m3, and the porous foam 20 is directly in contact with the lower main surface 102 and one side of the vacuum insulation panel 10 and integrated into one body during the foaming process; the vacuum insulation panel The upper major surface 101 of 10 is flush with and exposed to the upper surface 201 of the porous foam body 20 . The lower surface 202 of the porous foam body 20 covers the rigid trim material layer 30 . The closed cell ratio of the porous foam body 20 is greater than 60%; the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com