Double-shaft rack opposed engine

A technology of engines and shaft teeth, which is applied in the field of engines, can solve the problems of complex structure of crankshaft engines, unstable power transmission, heavy weight, etc., and achieve the effects of compact structure, high work efficiency and small vibration

Inactive Publication Date: 2015-10-14

孙书伟

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the shortcomings of the old product crankshaft engine with complex structure, heavy weight, large volume, large loss, low efficiency, and unstable power transmission

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

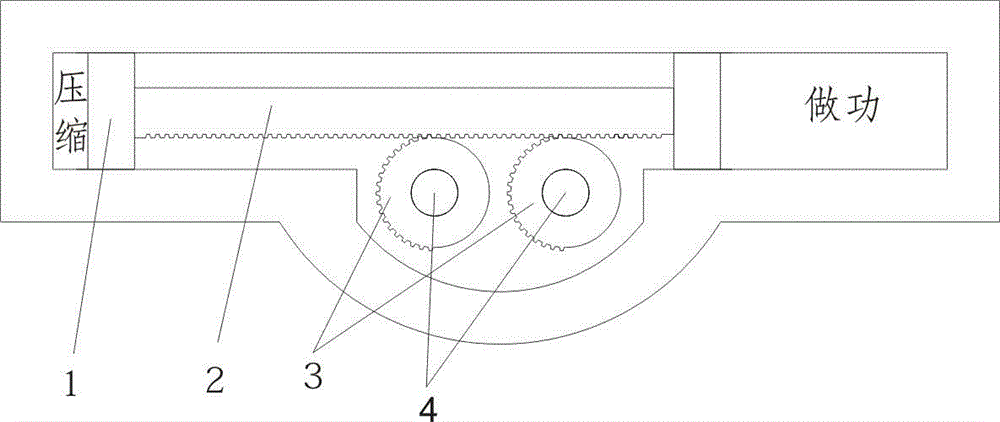

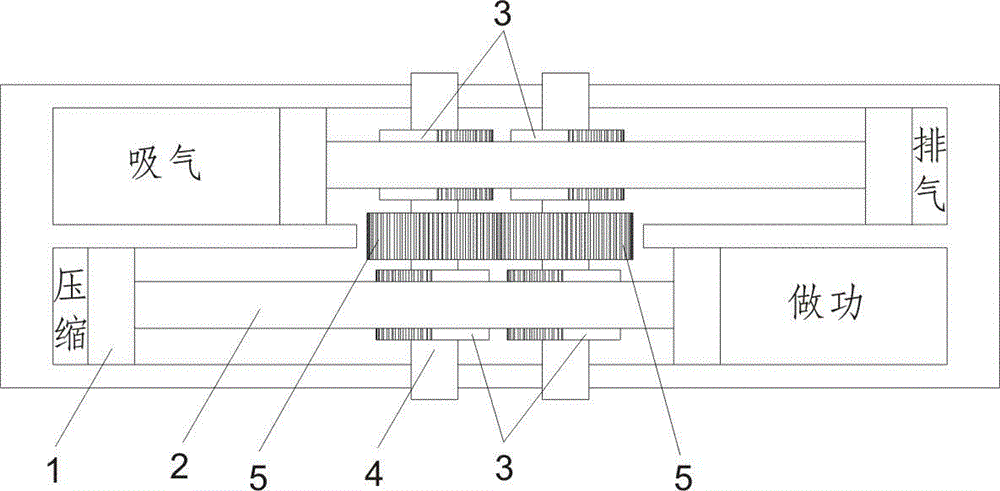

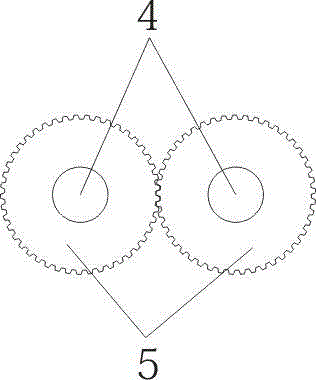

[0007] Double-shaft rack-and-rack engine, the four combustion chambers run the intake, compression, power, and exhaust strokes in sequence. Under the constraints of the double-shaft gear set, the two half-circle gears are alternately connected to the racks of the connected pistons. , convert the back and forth movement of the rack into a circular motion, and output power.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a double-shaft rack opposed engine which is used for providing power for automobiles, ships and the like. The double-shaft rack opposed engine aims to overcome the defects that old product crankshaft engines are complex in structure, high in weight, large in size, large in loss, low in efficiency and instable in power transmission. According to the technical scheme adopted by the double-shaft rack opposed engine, a crankshaft and a flywheel of a traditional engine are omitted, and innovative racks, pistons, gear sets and semicycle gears are adopted. Movement of the pistons is transmitted to a gear structure through the racks, the semicycle gears and the racks / gears work alternately, and back-and-forth movement of the racks is changed into circumferential movement. The structure is simplified; the weight is lowered, and the size is reduced; friction is reduced; the service life is prolonged; vibration is small and noise is low. Particularly, power arms of the gears are equal, the power, torque and speed are output linearly, in this way, the stability is extremely high, and the acting efficiency is high. The double-shaft rack opposed engine overcomes the defects that the power arms of the crankshaft of the traditional crankshaft engine change continuously, the power, torque and speed are output in a pulsed mode, in this way, the stability is extremely poor, and the acting efficiency is low.

Description

technical field [0001] The present invention relates to: a kind of engine, is used as the power device of automobile, ship etc. Background technique [0002] At present, the engine used is the crankshaft engine invented decades ago. Although the technology is mature, it is too old and there is no room for improvement. The structure is complex, heavy, bulky, difficult to process, and the friction loss of the crankshaft is large. Because the crankshaft power arm is constantly changing, the output of power, torque, and speed is pulsed, which is very unstable and has low work efficiency. Contents of the invention [0003] In order to solve the shortcomings of the old product crankshaft engine with complex structure, heavy weight, large volume, large loss, low efficiency, and unstable power transmission. The technical solution adopted by the invention is: the crankshaft of the traditional engine is canceled, the structure is simplified, and the weight and volume are greatly re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02B75/32F02B75/24

Inventor 孙书伟

Owner 孙书伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com