An inline flexible seat flange for valves

An in-line, seat flange technology, used in valve lifts, valve devices, engine components, etc., can solve the problems of difficult on-site grinding, high waste of maintenance materials, and inability to disassemble valve seats, and achieve valve opening and closing. Flexible and reliable, good market promotion value and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

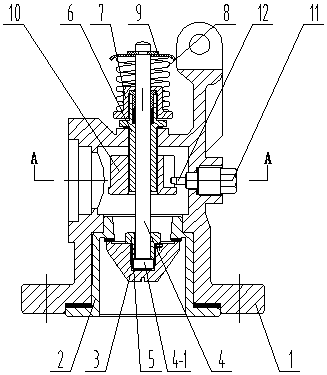

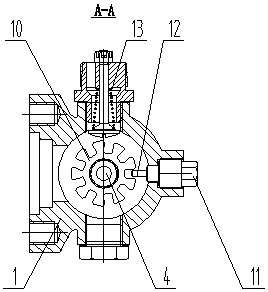

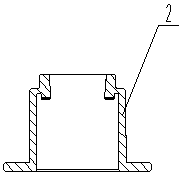

[0013] Such as figure 1 , 2 , 3, the present invention includes a valve seat 1, which also has a flexible valve seat assembly and a pressure regulating assembly, and the flexible valve seat assembly includes a flexible valve seat 2, a valve disc 3, a valve stem 4, a screw sleeve 5 and an elastic valve switching device , the flexible valve seat 2 is set at the air inlet of the valve body chamber 1, the valve disc 3 is provided with an internal thread hole, one end of the valve stem 4 is provided with a boss 4-1, and the boss 4-1 of the valve stem 4 is inserted into At the bottom of the internally threaded hole of the valve disc 3, the screw sleeve 5 is set on the valve stem 4, and the screw sleeve 5 is locked in the internally threaded hole of the valve disc 3, and against the boss 4-1 of the valve stem 4, the elastic valve The switch device includes a pressure regulating sleeve 6, a lower spring plate 7, a spring 8 and an upper spring plate 9. The upper and lower parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com