Fermented milk without food additives and preparation method thereof

A food additive and fermented milk technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as impure flavor, complex production process, rough taste, etc., and achieve the effects of reducing water separation, increasing viscosity, and restoring texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

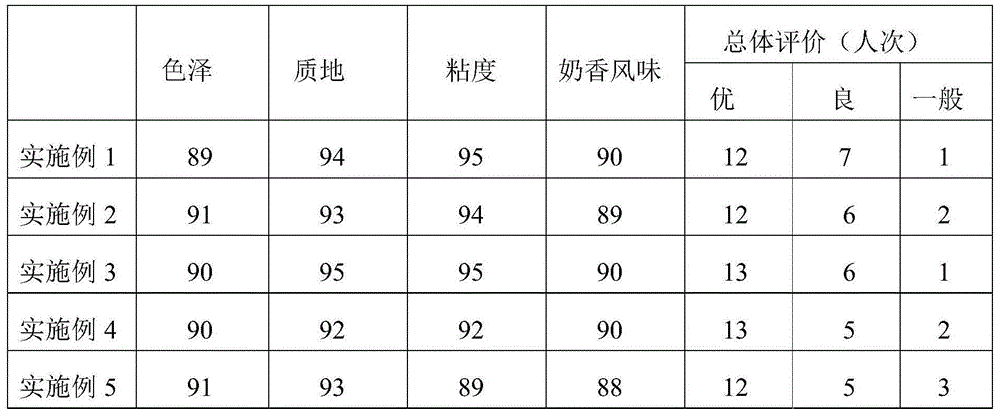

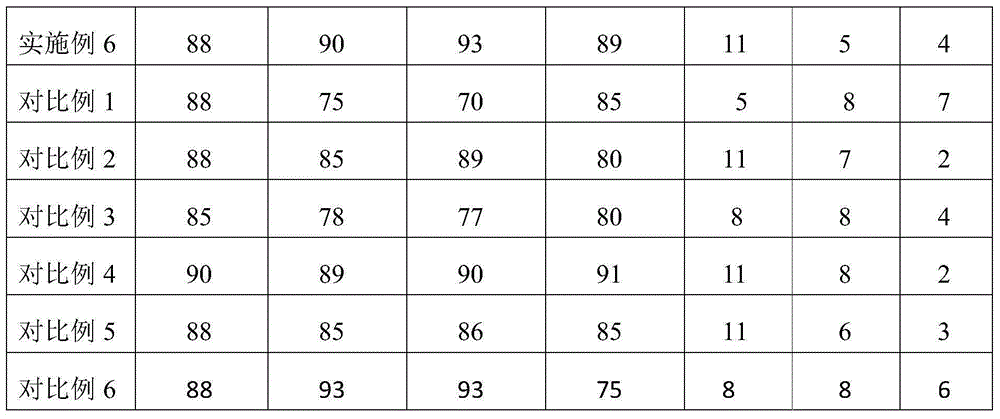

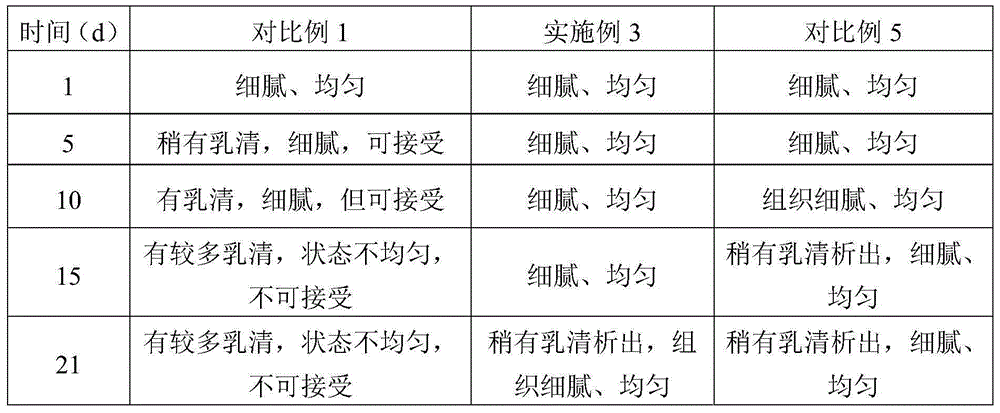

Examples

Embodiment 1

[0022] 1) Ingredients: Preheat 937g of fresh milk to 50°C, add 2g of milk protein powder (80% protein mass percentage), 60g of white sugar, and 1g of cream, mix well and stir evenly to obtain a feed liquid;

[0023] 2) Homogenization and sterilization: Heating the feed liquid to 65°C and homogenizing at 18 MPa, holding it at 95°C for 10 minutes, and cooling to 25°C to obtain the cooled and sterilized feed liquid;

[0024] 3) Primary fermentation: under sterile conditions, inoculate 1×10 Streptococcus thermophilus 6 cfu / g, Lactobacillus bulgaricus 2×10 6 cfu / g and Lactococcus lactis 1×10 6 cfu / g is fermented as a fermentation strain, and fermented at 25°C for 5 hours to obtain a primary fermentation product;

[0025] 4) Secondary fermentation: the temperature of the primary fermentation product is raised to 37°C to continue fermentation until the acidity at the end of the fermentation reaches 70°T, and the secondary fermentation product is obtained;

[0026] 5) Cooling and p...

Embodiment 2

[0029] 1) Ingredients: Preheat 860g of fresh milk to 60°C, add 10g of milk protein powder (50% protein mass percentage), 80g of white sugar, and 50g of cream, mix well and stir evenly to obtain a feed liquid;

[0030] 2) Homogenization and sterilization: Heating the feed liquid to 65°C and homogenizing at 20 MPa, holding it at 90°C for 5 minutes, and cooling to 35°C to obtain the cooled and sterilized feed liquid;

[0031] 3) Primary fermentation: under sterile conditions, inoculate 2×10 Streptococcus thermophilus 6 cfu / g, Lactobacillus bulgaricus 2×10 6 cfu / g and Lactococcus lactis 1×10 7 cfu / g is fermented as a fermentation strain, and fermented at 35°C for 3 hours to obtain a primary fermentation product;

[0032] 4) Secondary fermentation: the temperature of the primary fermentation product is raised to 45°C to continue fermentation until the acidity at the end of the fermentation reaches 80°T, and the secondary fermentation product is obtained;

[0033] 5) Cooling and ...

Embodiment 3

[0036] 1) Ingredients: Preheat 900g of fresh milk to 60°C, add 5g of milk protein powder (70% protein mass percentage), 70g of fructose, and 10g of cream, mix well and stir evenly to obtain a feed liquid;

[0037] 2) Homogenization and sterilization: Heating the feed liquid to 70°C and homogenizing at 18 MPa, keeping it at 95°C for 5 minutes, and cooling to 33°C to obtain the cooled and sterilized feed liquid;

[0038] 3) Primary fermentation: under sterile conditions, inoculate 1×10 Streptococcus thermophilus 5 cfu / g, Lactobacillus bulgaricus 1×10 5 cfu / g and Lactococcus lactis 5×10 7 cfu / g is fermented as a fermentation strain, and fermented at 30°C for 4 hours to obtain a primary fermentation product;

[0039] 4) Secondary fermentation: the temperature of the primary fermentation product is raised to 40°C to continue fermentation until the acidity at the end of fermentation reaches 75°T, and the secondary fermentation product is obtained;

[0040] 5) Cooling and post-rip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com