A method of grinding and magnetic separation

A magnetic separation and dry grinding technology, applied in the field of grinding magnetic separation, can solve the problems of water pollution and high energy consumption, and achieve the effects of simple separation method, high energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

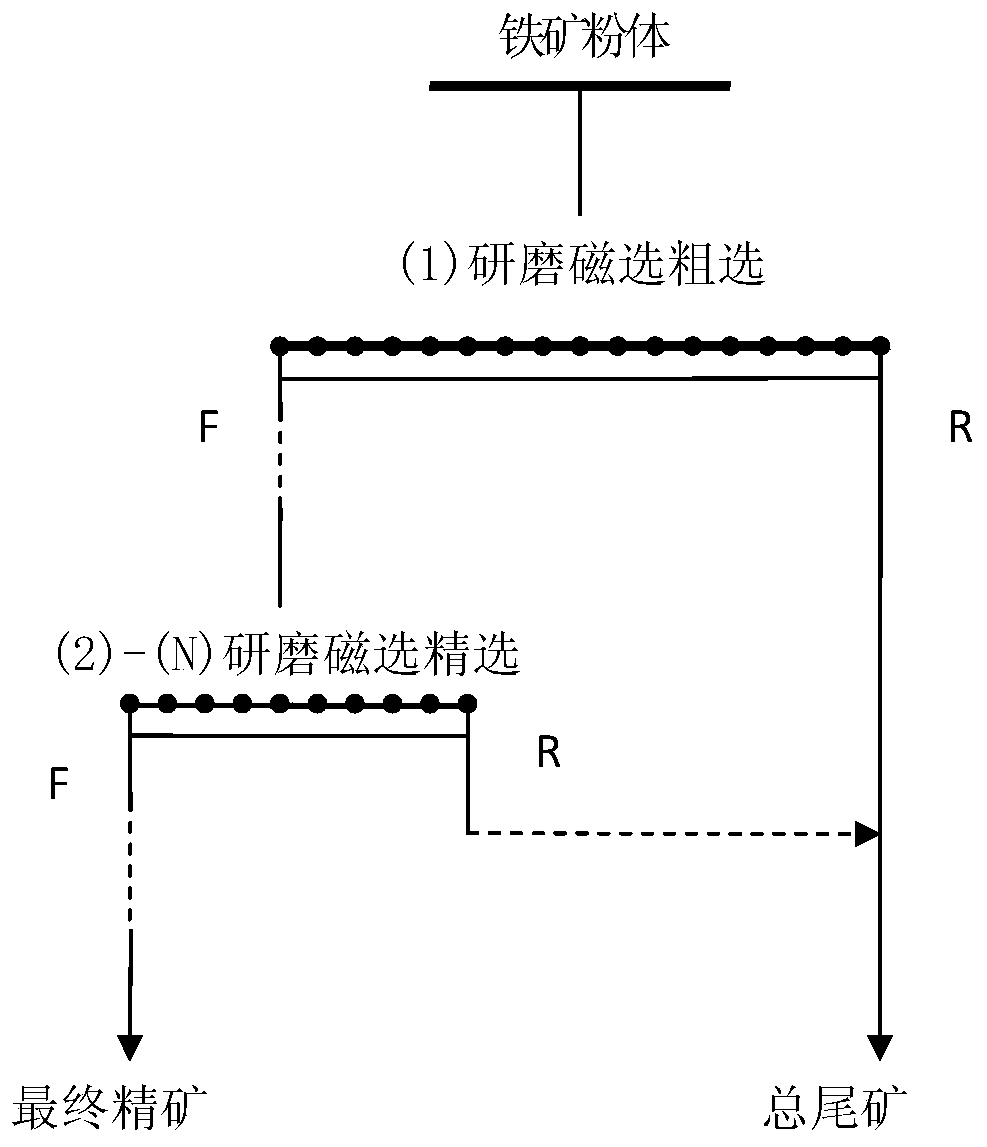

[0019] Such as figure 1 As shown, a method of grinding and magnetic separation, the ore powder to be selected is 67.15% iron grade, of which magnetic iron is the main one, and 89% of the iron ore has a particle size below 71 μm.

[0020] The steps of a grinding and magnetic separation method are as follows: (1) dry grinding and magnetic separation of raw material powder to obtain concentrate 1F and tailings 1R; (2) wet grinding and magnetic separation of concentrate 1F to obtain concentrate 2F and tailings 2R; (3) Wet grinding and magnetic separation of concentrate 2F to obtain concentrate 3F and tailings 3R; (4) wet grinding and magnetic separation of concentrate 3F to obtain concentrate 4F and tailings 4R; (5) Wet grinding and magnetic separation to separate concentrate 4F to obtain concentrate 5F and tailings 5R. Concentrate 5F is the final concentrate with an iron grade of 69.62% and an iron recovery rate of 99.00%. The combined tailings 1R-5R are the final tailings, and...

Embodiment 2

[0024] The iron concentrate to be selected has an iron grade of 66.02%, mainly composed of fine-grained magnetic iron. Press as figure 1 A method of grinding and magnetic separation is shown.

[0025] The specific separation steps are: (1) Dry grinding and magnetic separation to separate raw material powders to obtain concentrate 1F and tailings 1R. The iron grade of concentrate 1F is 67.40%, and the iron recovery rate is 99.23%.

[0026] The involved dry grinding magnetic separation method is the same as in Example 1.

Embodiment 3

[0028] The iron concentrate to be selected is the same as in Example 2. Press as figure 1 A method of grinding and magnetic separation is shown.

[0029] The specific separation steps are: (1) wet grinding and magnetic separation of raw material powder to obtain concentrate 1F and tailings 1R; (2)-(8) wet grinding and magnetic separation of the concentrate obtained in the previous step to obtain Concentrate 8F and tailings 2R-8R. Concentrate 8F is the final concentrate with an iron grade of 68.91% and an iron recovery rate of 98.33%. The combined tailings 1R-8R are the final tailings, and the water in the separation process is recycled.

[0030] The wet grinding magnetic separation method involved is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com